Hello, I am tray.

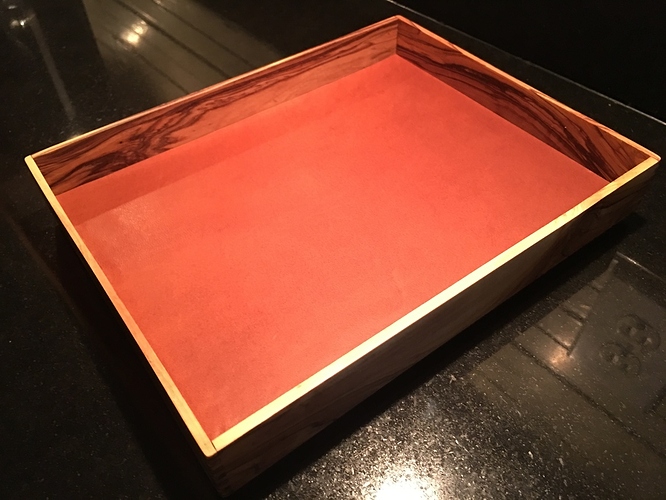

I was commissioned by a friend to make a birthday gift for her friend. She’d seem some of my laser projects and didn’t know what she wanted, just something lasered, and quickly – she requested it on Saturday and it had to be ready on Thursday. We settled on a valet tray, 7 x 9" x 1-1/2" (178 x 229 x 38mm) in size. Trays are really simple, but you can make an impact even with a project this easy if you take the time to get the details and materials just right.

Notes:

- All woods used are 1/8"

- All “hero surfaces” (that is, not the bottom) are sanded to 1500 grit

- The finger joints were standard fingers but fairly thin at 0.1" (2.5mm)

- The bottom was sanded to 600

- All woods are finished with clear Danish oil.

- Hidden detail: there is a middle layer (of baltic birch) on the base, between the backing and the leather. This gives it a bit more heft and rigidity.

- No proofgrade was harmed in the making of this tray, as such, please don’t ask for settings.

I started by choosing the wood from what I had on hand. I’d been looking for a smaller project for these olivewood pieces I had gotten a while ago from a small company in Jerusalem. I had a 2 quare foot piece of cow leather that has an excellent finish on it, I decided it would be a perfect match, and add some elegance. It’s a really soft leather to the touch, feels very luxurious.

Olivewood, Cow leather

Lighting is tricky, it can make the wood look very different from shot to shot. In reality, the wood is a honey gold color with dark brown veins. It’s really striking, but surprisingly consistent to cut. So many woods that have variety like this are hard to deal with (I am talking to you Ambrosia Maple and Zebrawood), but olivewood was surprisingly compliant.

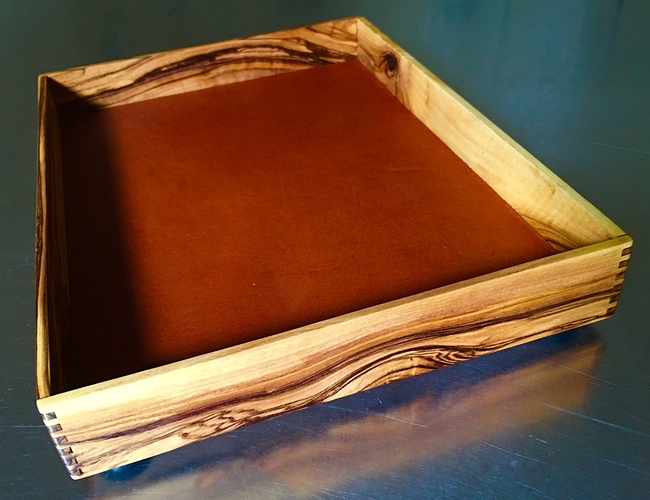

Olivewood, Cow leather

A very similar shot to the last, but turned 180 degrees. You can see the variety in the wood, it’s a really impressive and interesting species. One note of caution: It sands very easily. I wouldn’t call it a softwood exactly, but it’s easy to oversand it and make thin spots if you’re chasing a surface imperfection. As always, I found this out the hard way and wasted 2 “sides”.

Olivewood, Cow leather

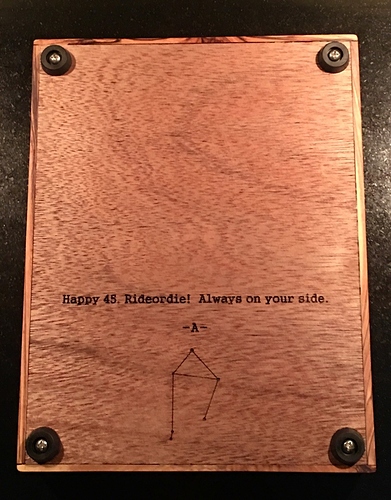

The bottom is engraved for a touch of personalization. Typeface and inscription were the client’s choice, I added the star chart for Libra – The client is into astrology, so it seems apropos. Client loved the idea, and here we are. You may have noticed the rounded corners, they were manually done with a sanding block by eye. See the previous note about the olivewood sanding very easily, these corners weren’t difficult to shape, only taking about 2-3 minutes each.

Meranti Lauan, Olivewood, Rubber screw-in feet with stainless steel screws

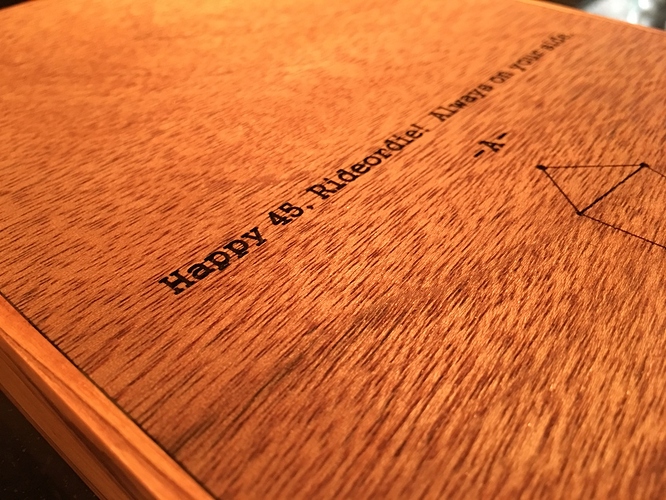

A close up of the engraving. The surface quality of the meranti is interesting, not exactly porous, but definitely textured. I thought the darker color would complement the darker tones in the olivewood, moreso than BB ply which is my usual go-to.

Meranti Lauan, Olivewood

Overall, I love the olivewood, and will be ordering more, but it does have its challenges.

- It’s a bit soft

- it has so many strange grain lines that it sometimes cracks ( I didn’t crack any pieces, but 2 or three already had cracks in them, and I had to cut my pieces around those).

- I can only source it by the pound in 1/8" with no guarantee of dimensions. This means I was limited to a sort of “find the right project for the material” mindset. I’ve reached out to the seller to see if they’ll do a run of properly dimensioned 1/8", they already sell 1/4" in proper sizes. Will update if I get a reply.

But wow does it make an impression. Worth the small drawbacks.