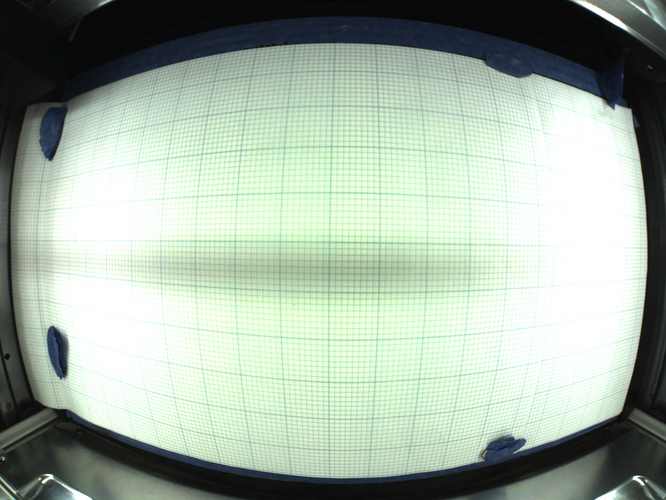

Not so surprising. The original snapshot from a lid camera is a fisheye image. It’s mathematically straight forward to remap the image to match reality but will still have significant errors at the image edges since each GF lid lens is slightly different.

Check out the original and remapped images from the link below. (@scott.wiederhold)