A person brought me back a sign that I carved for them asking for a border. It’s the tiniest bit too big for me to work on in the GF. I’m talking a fraction of an inch. I’ve messed with taking the tray out and bringing it down as low as possible and I’m almost positive that I’m SOL but the sign itself is only 12 inches high. The border needs to be at roughly 11.7. Width I can squeeze in but before I give up I figured I’d take one last stab and ask here.

Some people have cut the bottom out of their machines.

Mine is still under warranty so that’s a no go right now but I’ll look into it once I can. It’s so frustrating because if I remove 1/8 of an inch I can get it. I’m so close. This dude is driving me insane!Yes, the customer is always right but his original plan was for a 10x16 sign on 1/4 plywood. Then he changed his mind and wanted it 12x19 on cherry. I told him some design elements would change due to the size and he said it was fine. Now he’s upset because I couldn’t fit the border on there. I agree a border would look great but the sign is just too darn big now. I was hoping I could squeeze it in. I may try to freehand it but the sign overall is beautiful so I’m bummed he doesn’t like it. The camera on my phone is cracked so it’s hard to tell but I think it came out great.

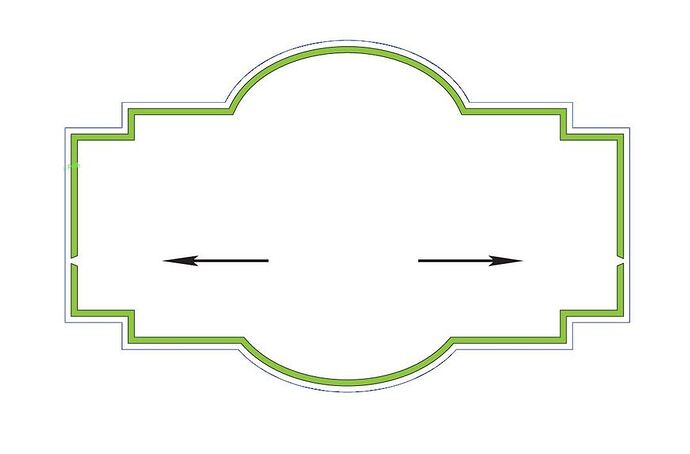

Make a broken border. (Put a swirl or something where it does not meet at the sides.) Or break it at the arrows.

Then do half. Flip it over and do the other half.

So your meaning is not lost on misconstrue what dimension is fighting you? Thickness or Y?

That’s a good idea! The original had the full border in the same shape as the sign but maybe I could convince him to go with a different one.

I think it would look good if you broke it at the arrows…might look like they were piercing the border. (Would look deliberate.)

I’m having a hard time picturing it but my brain isn’t working anymore. I had 130 orders to get out today and I’m still working so trying to do anything creative right now is a challenge. I may be able to think of something in the morning though. This is the first time I’ve ever had a complaint so I was pretty upset. Totally my fault because I should have been more specific but I was still pretty bummed. The arrows don’t go all the way to the edge. They have the same distance as the date but, you’re right, it may be a struggle trying to fit something in there.

Something like this…doesn’t matter how large the break is, as long as there is a break so you can flip it around.

Gotcha. I’m not having a problem with the sides as much as I am with the top and bottom. The design is too tall.

Yeah, that’s why you have to split it. Each part of the border can be handled individually.

Oh heck…let me see if I can find the description for it…it requires careful placement or use of a jig…we did it on a clock face.

Here you go:

Yeah, confusing until got thru a couple answers–it’s the X&Y, and not the Z (depth) she has issue with…

If you break the design you can print the bottom and then flip the material and separately print the top upside down.