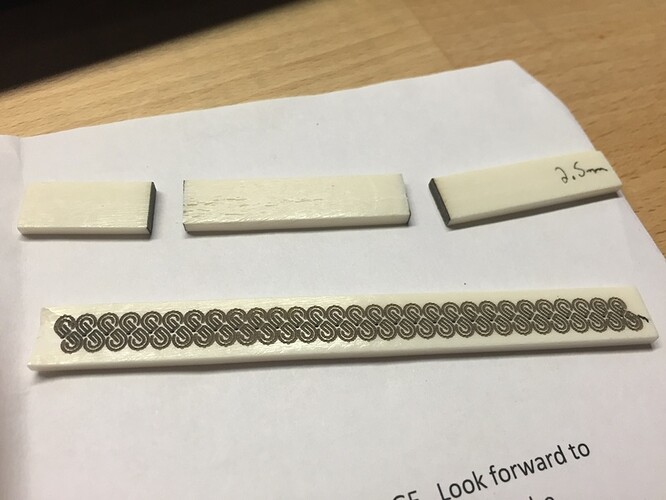

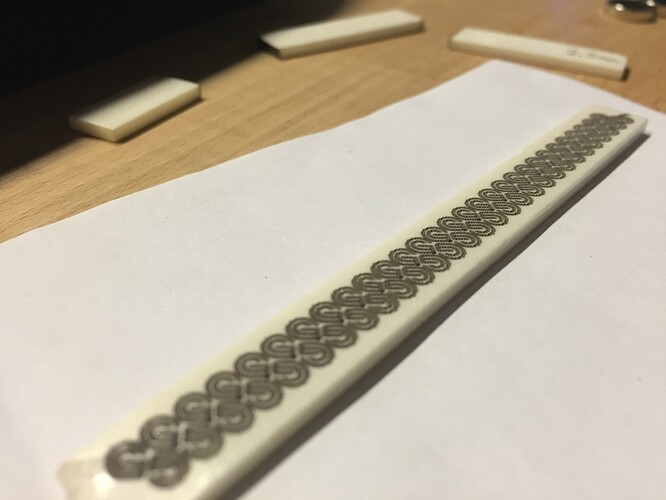

@jdodds sent me some bone to test and after a long journey and some procrastination, I finally got to testing it! I engraved it at pretty high speed to great results - the etching is very high contrast and looks absolutely amazing. I also was able to cut through at a much lower speed. Folks here are excited about the implications this has for jewelry making, but as the token vegetarian I’m not sure this will be a medium I work in much ![]()

Wow. This is so cool. Be great for engraving bone in handles for things and above all buttons.

This will be so useful for so many things…custom knife making, for example…

Very cool. Are there bad oders when cutting bone like this? @aeva

I didn’t notice any while it was cutting and the filter was running, but afterwards you could definitely smell some bone-ish odors

Will my skin grow back?!

This looks very promising.

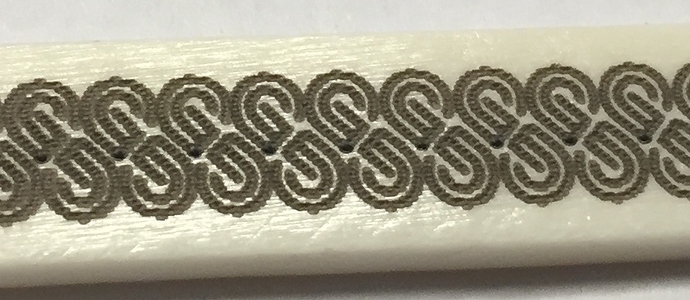

@aeva Are the pixelated edges a result of low resolution artwork, or an artifact of cutting bone?

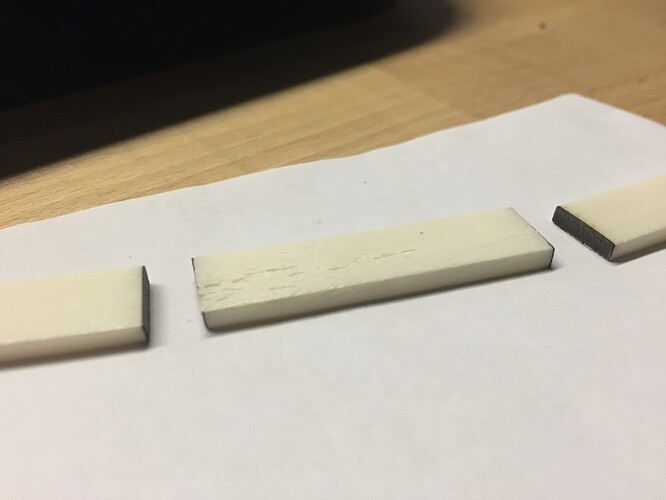

The bone was just raw cut and therefore very porous. My guess is that polishing the bone before laser processing would have different results.

I thought so too, but then noticed that the pixellation seemed to be very regular:

Certainly that’s not the smoothest edge we can expect with the Forge, is it?

I think @fan-of-glowforge has a valid question.

Take a look at this:

Looks like rastering marks. Or that’s where the laser is powering up, makes a deep cavity then powers off.

Multiple passes maybe?

Looks like the edge roughness corresponds to the fiber grain of the bone surface…

Dunno the ‘dimples’ are symmetrical between all the logos

Isn’t bone built like a honeycomb? Therefore you have a calcium wall - air pocket pattern. With a laser delivering constant energy to a regularly-irregular structure I could see a pattern manifesting itself of which a pixelated effect could be one. Looking at the reflections the material certainly has a series of ridges in it. I’ve always figured engraving woods with wild grains will be an act of frustration. Dan has said the less uniform your material the less precise the result, which only makes sense. Plus, aeva only had a short amount of time for fine-tuning power and speed. I wouldn’t grow too worried at the the moment that we’ve all bought an 8-bit laser cutter (ok - technically we did from the 256-greyscale point of view, but that’s not what I mean.)

Nothing from these pictures indicate to me that there was any power adjustment used. Probably still using the original power supplies on the demo unit without 256 levels. On or off only with speed adjustments. The rastering is more likely the resolution of the raster stroke. We’ve seen other demos where it was stated they were only using about 1/4 of the final production resolution. This might not be representative of production capability. Though it’s much easier to get the stated precision with continuous curves that it will be using this raster technique.

That’s a good question and one I don’t have an answer to right now. I’ll do some digging to investigate.

Wow, where would one get bone to work with?

Easy to find bone blanks. Luthiers and knife makers use it a lot. Large pieces are harder to get. It’s bone after all. Guess you might dig up a Mastodon. Try ebay (Bone blanks)

or walk into the woods or down a country road!

Too bad this racoon skull that my mom found by the creek is taller than 1.5"

It’s just too easy to clean up the edges with a vector line. I do not see this as a problem.

Very cool sample!

Custom butcher shops have them. You might be able to get a good bovine femur, although generally they are sliced. Make some beef stock first though. I know a few folks who butcher their own and they give me tubs of bones for stock come January. I can it. You could also go the beetle route to get really nice clean bones. Find a taxidermist and they might help you there.