What a process to nail down the perfect settings for a Non-Proofgrade application. I haven’t used a lot of Proofgrade (yet) but it makes one realize the value of “click and go”. Part of what complicates the process is that I’m working with multiple substrates that are adhered together, where smoke and char just won’t work for the end product, and that I’m cheap. I don’t want to mask these if I can avoid doing so - one, because it’s an additional expense to production, and two, it’s many extra steps to weed each and every individual puzzle piece.

I finally got around to testing the .05" chipboard. The end product is significantly thinner than the .10" chipboard (duh, right?). It’s not, but it feels like it’s less than half. The final caliper dimensions, with the picture mounted, adhered and special sauce (that I’ll mention below) come to .07", which is within the realm of good/strong jigsaw puzzle pieces. I personally would like to find something that is a bit thicker though… maybe something that calipers at around .09-.10" when finished.

The .05" stuff cuts a ton better than the .10" product. Chipboard is really freaking dense. I didn’t think it would take so much to cut through the .10". For the .050", I nailed down some settings of 350/Full Power/1 pass for a good, repeatable cut.

But, I was still getting some smoke stains on the bare paper in testing. I had tried sacrificial paper below, nothing below, some masking I took from PG material (not good, too much tack for photo paper), wiping it off, etc. Finally, I went and bought some varnish thinking maybe this will help keep smoke from getting in the paper itself and I can just wipe off any remnants. It will help with puzzle pieces anyways, since they need to be protected somehow (varnished, laminated, or other ways) Varnishing is just one way to finish photos and protect them from the elements, fingerprints, etc. I have both an aerosolized spray and a pure liquid that can be applied with a roller or brush.

I sent a few test prints to the printer, mounted them up on some chipboard and went the varnish route - doing a few with the aerosol and doing a few with the liquid varnish. I haven’t cut the liquid varnish yet… and I’m thinking that’s what I’m going to do in the future since it can be purchased in quantity much cheaper than the aerosol. And it’s quite a bit safer… respirator definitely needed with the aerosol. And a warning - if you use this, make sure that it is completely and totally dry before you stick it in your Glowforge. Once dry, it’s inert and no problem but still wet… just don’t do it.

Anyways - the .05" chipboard cuts like a dream. And the varnish - wonderful. Smoke is no longer a problem, with or without sacrificial paper below (I will continue using it just to avoid potential flashback from the honeycomb).

I sent my first cut at 350/Full Power/.07" Focus Point (top of material) and it cut through great and no smoke stains! Woohoo!

I felt that I could get the kerf a little tighter yet, so I set the next piece up to process. Side now - I had varnished the back side of this one as well as the front. Set up the same cut settings except changed the focal point to mid way through the chipboard and paper (at .035"). Even better!

Here are a few pictures showing the difference. Both samples were cut face down (@paulw) with a piece of sacrificial paper below.

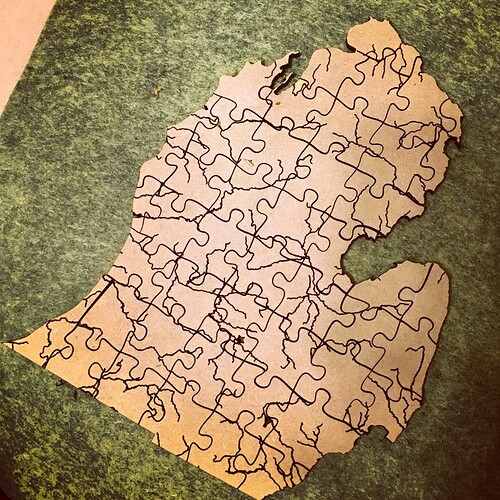

Figure 1: Cut at 350/Full Power/.07" focus point (top of material). Not too shabby. I have taken the puzzle apart and reassembled it on the Glowforge bed at this point.

Figure 2: Same cut settings but moved focus point to .035" (midway through material). Don’t mind the miscut at the top from my trimming process - hey, it’s just testing, ok? ![]() Much, much less discernable kerf on the front of the image.

Much, much less discernable kerf on the front of the image.

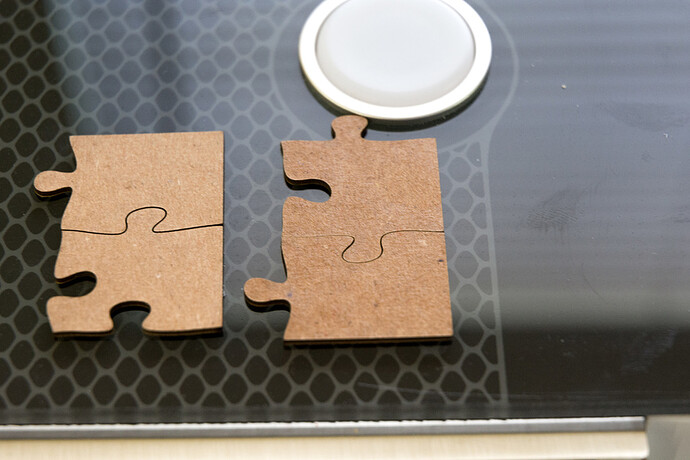

Figure 3: Comparing the cuts from the backside of the puzzle. Again, the puzzles were cut image down so the back is where the laser hits first. On the left is the first cut, focusing on the top of the chipboard. On the right is the second cut, focusing at the middle of the chipboard.

Figure 4: Naked Glowforge button! ![]() This is a top down view showing the difference between focusing on the top of the chipboard (top assembled pieces) versus focusing in the middle (lower assembled pieces).

This is a top down view showing the difference between focusing on the top of the chipboard (top assembled pieces) versus focusing in the middle (lower assembled pieces).

but for one offs, it would be a consideration! Since these will be packaged and both wholesaled and retailed, I have to keep costs pretty reasonable. It costs me about $0.95/sq ft to print (including ink and paper), so an 18x24 puts me at 2.85 for just a print to cut. The prep costs are pretty minimal per sq ft but I’m not sure what packaging is going to cost me. I need to mock up that design tonight and order some samples. The box I’m thinking of doing won’t be as cheap as others - but packaging sells.

but for one offs, it would be a consideration! Since these will be packaged and both wholesaled and retailed, I have to keep costs pretty reasonable. It costs me about $0.95/sq ft to print (including ink and paper), so an 18x24 puts me at 2.85 for just a print to cut. The prep costs are pretty minimal per sq ft but I’m not sure what packaging is going to cost me. I need to mock up that design tonight and order some samples. The box I’m thinking of doing won’t be as cheap as others - but packaging sells.