I’ve been immersed in another GF related project, so I haven’t had much time to finish the fine tuning.

I did get it motorized:

The gear connected to the motor is the same one from the plans that is used to drive it manually.

I purchased the motor from McMaster-Carr. I picked up both the 5 and 7 RPM versions. The 5 RPM has more torque, which aids in smoother running, but the 7 RPM is more visually appealing. If I was only going to purchase one, I would get the 7 RPM - but you will need to fine tune the mechanism to be smooth as silk.

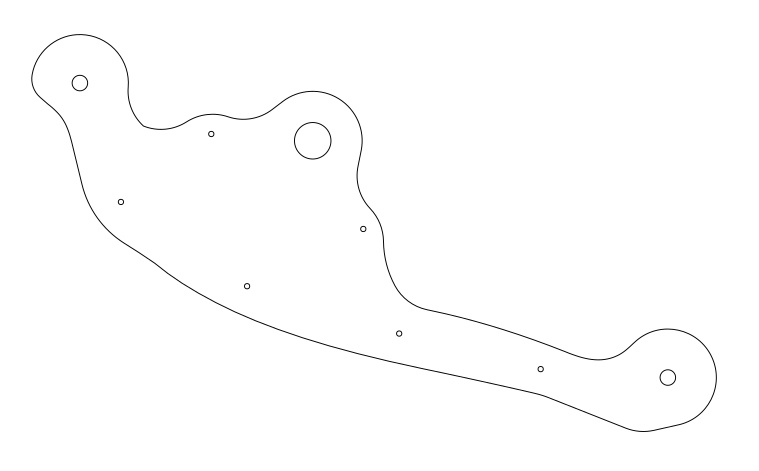

This is the motor bracket design I whipped up:

Discourse Friendly ZIP’ed SVG: MotorBracket.zip (4.0 KB)

The four small holes along the bottom were intended to add screws for additional strength. They don’t seem to be needed and could be omitted.

As far as construction tips…

You’re going to curse GF for not having the capability to directly import DXF or kerf compensation. Easily, one of the longest and most tedious parts of this process was manually converting and correcting the large number of parts for this project.

An open offer to anyone undertaking this project: If you want to save some time, I can send you my converted, kerf corrected, GF ready SVG files (to protect the intellectual property of the artist, you’ll need to provide me with proof of purchase of the plans, and agree not to redistribute to them to others without the same).

I had fairly good luck building up the thicker components by gluing layers of Proofgrade together. In places where it took three layers, I used draftboard for the middle piece. A quick sanding with some coarse grit on the mating surfaces before gluing is necessary to get the finished PG to adhere. In the end, they are surprisingly rigid.

The downfall to making the pieces with Proofgrade was that they don’t always build up to the exact thickness of the plywood used in the plans. You’ll find that in some places you’ll need to add and extra spacer or two. YMMV.

Also due to the thickness differences - some of the parts you need to machine will need slight adjustment. You’ll know those when you see them.

The pivot blocks for the wings will not hold up if you make them from wood. I made them from 1/2" acrylic from Inventables. See this post for details on cutting acrylic that thick - you’ll get pretty good results.

All around, this was a pretty enjoyable build. It was the first real project I took on with the GF, and it helped me to develop my workflow.