I had a need to made some parts out of 1/2" clear cast acrylic. I bought the material from Inventables using my GlowCredit, and after a few stabs in the dark, wound up with this mess:

And, the first fire I had to put out.

It was time for something more methodical.

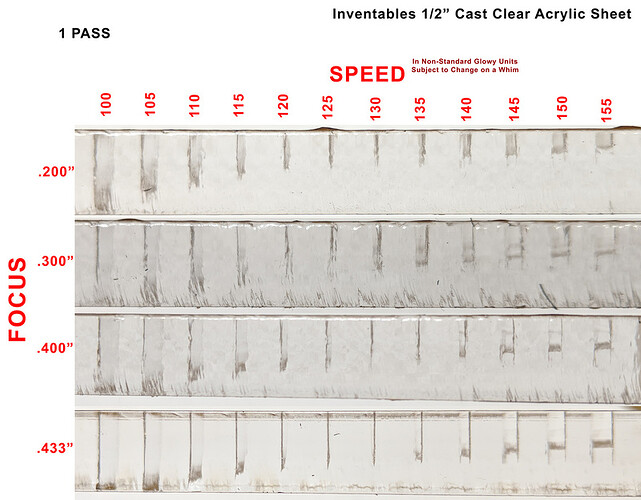

I give you:

These are single line, 1/2" in length cuts at various focal depths and cutting speeds. All are at 100% Basic Power.

.433" at 100 GlowySpeed gave fairly consistent cuts completely through. There were a couple of spots that didn’t quite make it (or melted back together, don’t know which), but for the most part it was a full cut.

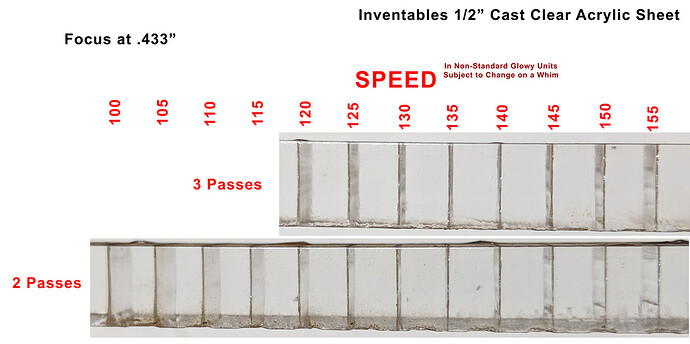

After deciding that .433" focus was giving the best results, I made the multi-pass attempts:

2 passes: 125 (barely), and slower all cut clean through. 100 left an undesirable undercut on the bottom.

3 passes: 140 and slower cut clean through.

Best bets:

2 passes at 120 was the best for a quick cut, with a kerf of .014" measured at mid cut depth.

3 passes at 120 left the cleanest looking cut, the least amount bottom distortion, and the same kerf: