Some thoughts on design, assembly, and what I’d change for next time:

I had considered using 1/4 material, and wanted to find the engraving setting that would produce a depth of 1/8" to fit the magnets in, but couldn’t find just the right settings for this to be consistent, so I just went with 1/8" material and more layers. I picked a 1" hex (flat-to-flat) based on measuring some dice, and then decided to also make the pocket 1" – 4 layers on each half. During assembly, I discovered 7 layers, even with the foam padding, was sufficient, so I went with one fewer layers on one side of each dice vault.

Some other project posted here used brass rods to align multiple layers, which seemed like a neat idea, so I decided to incorporate that into my design. The brass rods I selected are 2mm diameter. Some test cuts determined that a 0.034 radius circle gave a reasonably tight fit, but still insertable by hand, so I made my alignment holes that size. (I craft my SVG files both by hand (in a text editor) and in Inkscape – the SVG file format defines circles with their radius, so that’s what I think of them as, not diameter.) Interestingly, 1mm (radius) is 0.03937 inches, and the laser kern is reported as 0.005 inches, so my test fit of 0.034, plus the kern of 0.005, matches up to my calculated expected value. I had several problems related to these brass rods. I engraved a ring with the alignment holes along this ring. Because the holes were a tight fit, the top layer of plywood often chipped off between the engraved ring and the edge of the board, as I was pushing the rod through. This could have been fixed by using a slightly larger hole (ultimately I used a 3/16" drill bit to open up the holes). Having the rods come through exactly where I was engraving made it very difficult to get the end of the rod flat and even w/ the work. I used a combination at times of a Dremel w/ a cutoff wheel, tin snips, and a vertical belt sander to deal with the rods. The rods also bent easily, if I wasn’t careful. Next time, I’d consider using 18ga finishing nails instead, making the holes loser, using fewer alignment pins, or even none at all.

I used 1/8" Baltic Birch instead of proofgrade plywood because it costs less than half the price, and is available locally. Using it, however, does not have as nearly as nice of a finish, so I decided to add a polyurethane coating. This looks good, but adds significant time (several layers are needed), smells terrible, and requires ventilation. Next time, I’d consider using proofgrade for the top layers, or just add a single veneer layer instead. It might be possible to just use a veneer layer as the top layer without a solid plywood layer. I’ve never actually worked with veneer, so I’m more guessing here.

When gluing the layers together, I rotated each layer by 60-degrees (one step along my alignment pins), so that the grain of the wood would be crossing rather than aligning with the previous layer, thinking this would make it stronger. Ultimately, this was probably a bad idea, causing more problems than it solved. First, I’m not sure that the dice vaults really need this “added strength”. Secondly, plywood already rotates the wood between layers, so my rotating at the macro level didn’t really add much. Most importantly though, the circular disks of each layer are not perfect circles. I assume that this is due to slop/backlash in the Glowforge. They certainly all look circular, but when stacking several layers, there was as much as a 1mm difference between the edges of adjacent layers, when the hexes were as aligned as I could get them, and the brass rods were through all 6 alignment holes. This contributed to the rods bending slightly, making it all the more difficult to add the next layer. I expect that had I been careful to maintain the orientation from when they were cut, they would have fit together much better. Once together, I felt it was important to sand all the edges. Fortunately, I have a belt sander, so I did not have to do this by hand. The result of all this sanding, though, was that there were parts of the edge that still showed the black of the laser cut, and parts that were fresh sanded wood – not a good look. I could have sanded even more, but it was taking a lot of time and making a big mess of sawdust. I decided that the feel of the edges was good enough, and added a coat of black paint to hide any remaining imperfections.

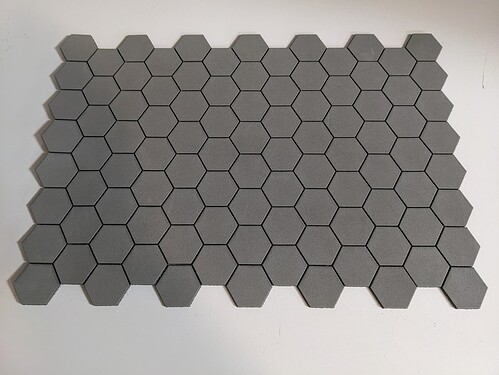

I had initially planned to line the dice pockets with felt, and ordered some sticky-backed felt from Amazon. Holidays, weather, and “global supply chain problems” means it’s been over two weeks since I placed the order, and the felt still hasn’t been delivered. I went to Joann to pick up some locally, but then found the 2mm eva foam, and decided to use that instead.