I used a blow dryer to heat mine up until I could slowly bend it to fit the curve of the back of my head…maybe that will prevent them from snapping and making the ear saver more comfortable

I already found someone on ETSY selling these. I have printed “Made and Donated by” (insert my shop name) to discourage the jerks that would do that.

Profiteering in a time like this is just disgusting.

What material are you using? We haven’t had any of the 2000 we’ve cut fail.

I’m using 1/8th clear acrylic. Thinking about switching to 1/4”

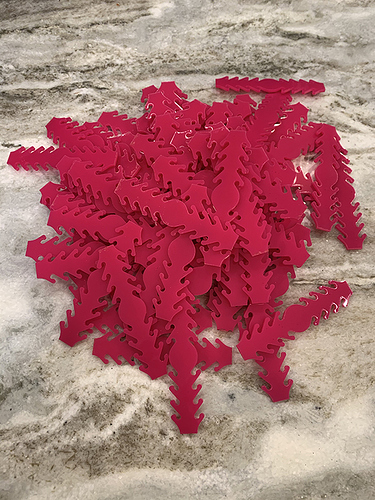

Just printed my 2nd sheet of them.

It takes just about as much time to remove the paper backing as the printing! However, I found that a strip of duct tape, rolled backwards around your fingers, does just the thing to lift off the paper backing.

at a minimum, you can unmask the top so you only have one side to peel after cutting. and you can pull all masking off and use a sacrificial sheet of paper underneath to take care of the flashback. much faster than peeling each individual clip.

I used my proofgrade medium acrylic, and found that some didn’t cut all the way through. I used 145 speed, 100% cut on th 1/8. I peeled the masking off the front and had the autofocus hit a small piece of painters tape on the corner of the acrylic. I left the back masking on to prevent flashing. All cut free and virtually no flaming…

Nice work! The demand is high. My wife and I are printing round the clock and we have donated over 5,000, with another 3 thousand being cut right now.

Made 24 and delivered to my brother who works at Layton hospital. He said they had 12 already and had been washing them between shifts. Its a small hospital so that should be enough for them. I just received my acrylic order and of course realized I never used the code for a discount🤦♀️, oh well.

Just waiting now to hear if anyone else needs any.

What settings do you use for the .060 acrylic? I’m new to GF Pro. I tried 400/100 and 1 pass isn’t cutting all the way through

is that just 1 pass?

yes, one pass. i need to do a cleaning on my machine, i’ve actually slowed it down a little on the more recent sheets to 205 after a couple didn’t cut thru.

thank you

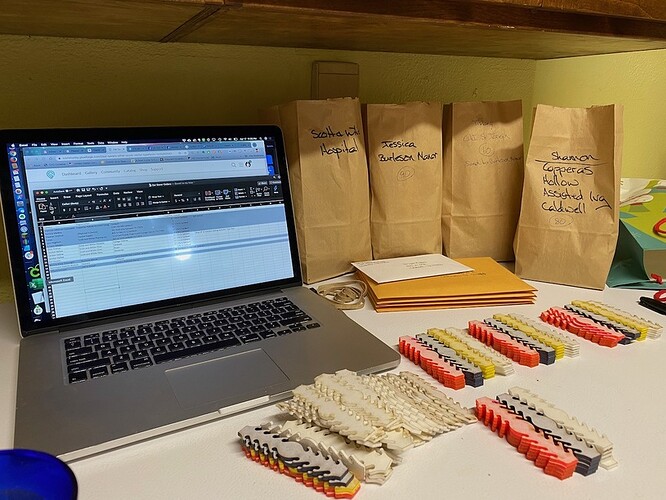

I’ve been posting a link to the Glowforge site in the local FB groups for the past few days. Got a few “likes” here and there, but nothing else until this afternoon, when the deluge suddenly hit. They’re all messaging me instead of filling out forms on the GF site, but I’ve got the only GF I know of in the area, so they’d have made their way to me anyway.

I spent the whole evening printing and packaging – 418 of them going out in the morning, and my laundry room is now a manufacturing and shipping center. (Gotta figure out a better way to organize, though, or we’ll eventually starve, 'cause all our food is in the freezer that’s providing my work surface!)

Smaller scraps might be used to cut buttons. I’ve been browsing for a button headband and almost every shop is saying something about buttons being hard to find.

I’m kicking myself right now for not taking care of my broken laser when we weren’t on lockdowns.

It is consistently not cutting all the way through for me, and tearing up my hands trying to force it. I’m using proofgrade acrylic. What should I change on my settings so that it will cut cleanly through the first time? I’m printing these out by the sheets and it takes too much time to cut them out with an exacto knife.

Dear All,

We have had a number of enquires in the UK from people wanting Ear Savers in the US who are yet to receive a reply. Although we would be happy to ship, shipping out of the UK at present is very slow and unpredictable. Is there anybody who could help with one particular enquiry. Supply required for an address in Jackson Heights NY ?

To Dan and the Glowforge Team, we have been getting great feedback from your design in the UK, we have sent out approx 1000 in 2 days and have a further 1000 to despatch tomorrow.

I am in New York City. I can take that order. Get a new supply of material on Monday. I would need to ship as I don’t have a car (typical new yorker). Feel free to share the info via my email. Wade@idoeventdecals.com

if you’re having trouble cutting through proofgrade, two thoughts.

first, have you cleaned your machine recently? if you’ve been cutting a lot and the lenses are getting dirty, you’re getting less power.

second, you can always slow down the speed a little to cut through. proofgrade acrylic is generally cutting at full power, so slowing down the speed a little will help cut that last bit.

In addition to @waders I can help too. I’m in CT so would mail it (even though I do have a car, unless it was a critical “we need them right now!” situation). I can make a few thousand with the acrylic I have on hand.