@rubbersoul79 found a sewing box design on Thingiverse she mentioned wanting to try. The designer noted that it was a work in progress and updates are forthcoming to correct stability and construction issues. But, it’s been a couple of years since the posting so I’m not sure they’re actually coming.

I volunteered to take a crack at it and fix any issues (I’ll post a remix on Thingiverse). Also one of the forthcoming additions was a top cover of some sort. So I added one of those too. My wife is into needlepoint and can use something to keep floss and tools handy without getting everywhere.

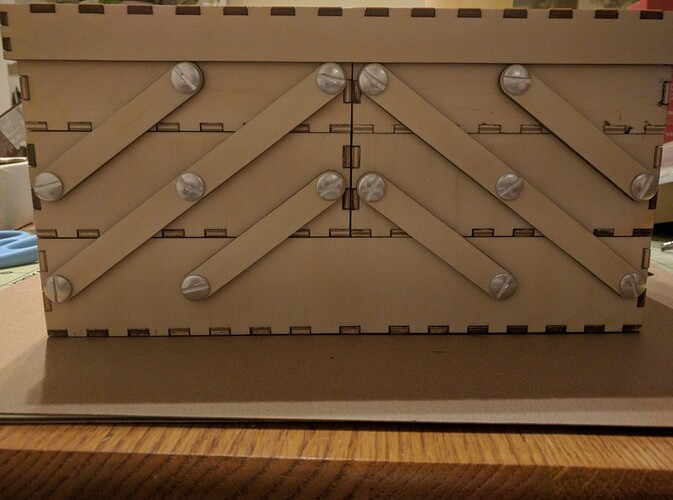

Enter sewing kit redux @rubbersoul79 style.

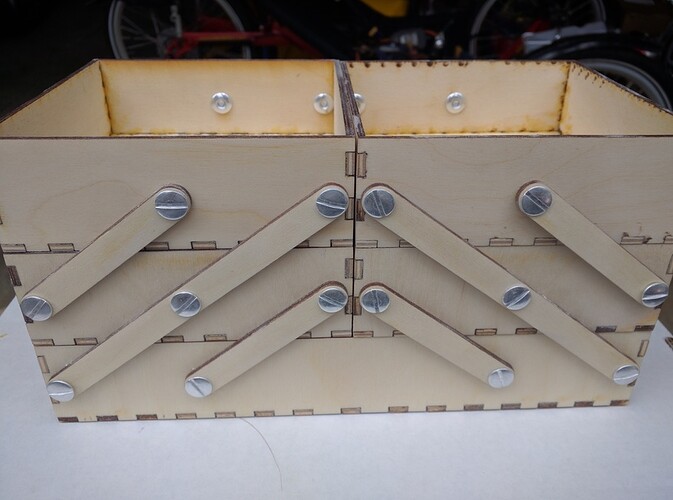

And opened up.

The Thingiverse files are all on one sheet that won’t fit into the Glowforge. First thing to do is break it up into groups that will fit. I decided to put the parts for the bottom and the side arms in one file and the 2nd and 3rd row boxes on another. I ended up creating a 3rd file for the top. Once the full bed is available I think this can be condensed into two files. For the not-faint-of-heart the parts could be done in layers in a single file with different colors for the parts on each layer - then in the GFUI just tell it to ignore the colors for the layer you’re not cutting. That would let you load a single project file and just replace the material on the bed as you “printed” layers.

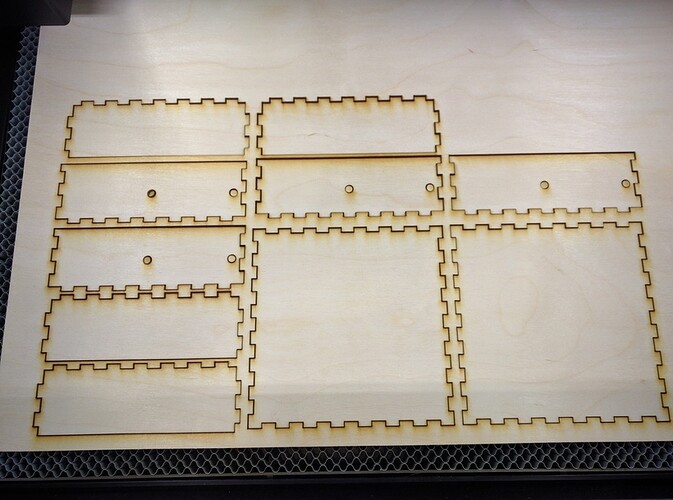

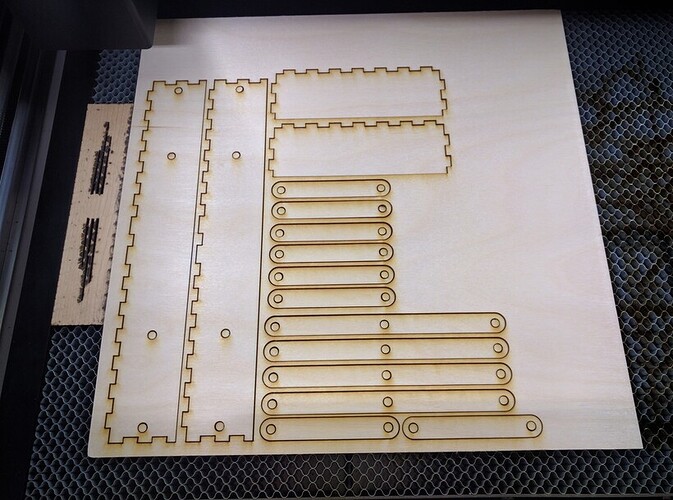

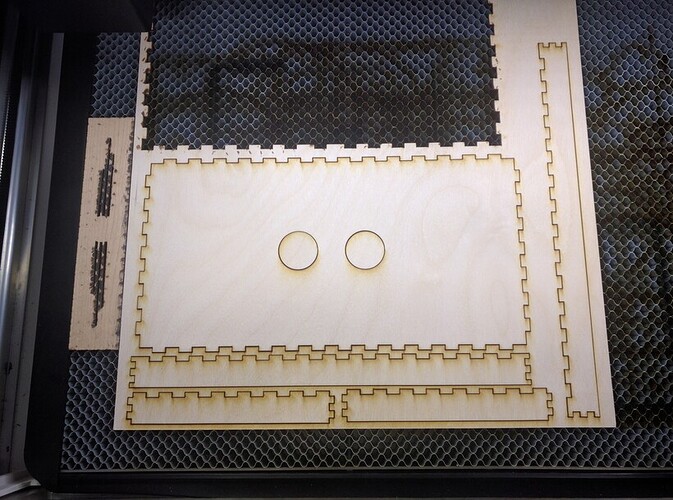

Here’s what the different files looked like after cutting. This is on Baltic Birch and unmasked because it’s my trial version.

Those are the individual boxes on the top two layers. You’ll need to do two of the middle and two of the upper boxes. Instructions are in cyan in the file so just tell the GFUI to ignore that color.

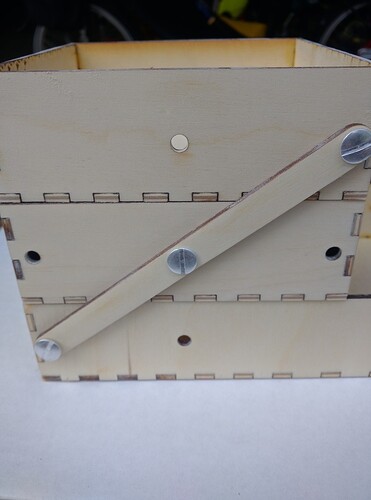

This picture is the base pieces and side arms used to keep everything together.

And the top.

The side arms are attached using sex screws. Okay, I knew them as Chicago screws or binding posts. But several people (& the original designer) referred to them as sex screws for obvious reasons.

Because the threaded screw fits inside a cylinder it allows the arms to rotate without binding but stays secure. When I have used them in the past I finish off by dropping a bit of super glue in the exposed barrel end to lock the screw in place. I didn’t do that yet because I’m going to be taking it apart to put a finish on it - a big benefit of Proofgrade is that step isn’t needed since they’re already finished.

I don’t usually mask because a quick 30 second hit with the random orbital sander will take care of the smoke staining and flashback burns. Except there are 38 pieces here. The half hour I spent sanding would have been 5 minutes of masking/weeding. Proofgrade of course is already masked taking care of that time as well.

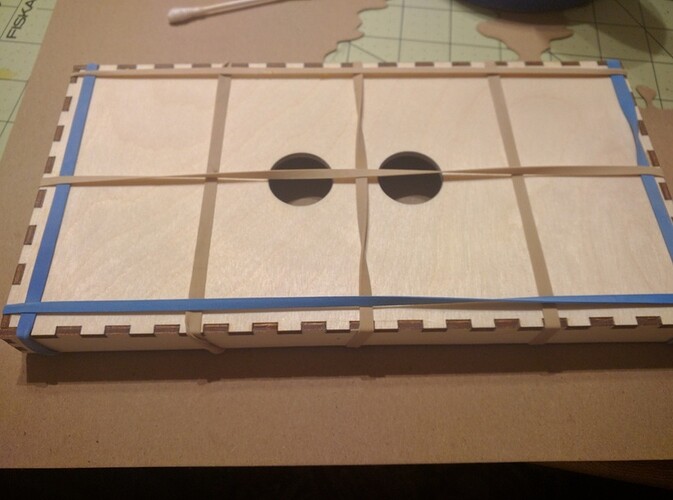

After sanding is done it’s time to assemble. Standard finger joints to make the boxes. Glue on the tabs and rubber bands to hold them together while the glue dries. I would have used my air pinner with 23ga pins but the smallest I can drive are 1/2" which are too long for the 1/8" plywood I’m using and is difficult to get precisely placed in the finger tabs. They will often shoot out a side vs driving straight into the ply. Glue and rubber band clamps for this project. Quarter inch materials or thicker get pinned as well.

Starting with the base I began attaching the side arms to the boxes with the Chicago screws. The female barrel half is inserted from inside the box and through the arm. I used 1/4" ones from Amazon.

https://www.amazon.com/gp/aw/d/B003O5GPHU/ref=sr_ph_1?ie=UTF8&qid=1493520540&sr=sr-1&pi=AC_SX236_SY340_QL65&keywords=100+chicago+screws#

$11 for 100 of them. Or $0.88 per screw at Lowes. You need 28 for this. Do yourself a favor go straight to Amazon. I got silver colored aluminum but they also come in stainless steel, black painted or brass. You should be able to match any finish you’re applying.

As you can see the 1/4" ones fit flush with the two layers of 3mm plywood.

The trick is to get the hole size correct. The designer had problems with this and ended up with a rickety construction that caused the boxes to rack and not open & close smoothly. The Lowes versions of these are 3/16" posts ad Amazon’s are 1/4" but they have the same diameter barrel. The Lowes 1/4" have a slightly larger barrel so get the screws before you cut your parts - you can modify the hole diameter as needed.

The holes in the files I’m attaching are 5mm which are perfect for the screws I got from Amazon. One of the files has 3 sizing holes you can cut before committing to the whole file - I tried 0.2", 5 and 4mm. 5mm was spot on - a hair larger than the barrel so the posts don’t bind but not so large as to allow the arms to wiggle which the 0.2" holes did.

Fits well and things move without binding. Moving on to the others.

Which brings up another point - you can do an arm at a time like this or you can do all arms & screws for a box like this:

I did one side of the kit arm first and the other side all arms by box. Doing all the arms for a box was easier to get the female sides of the screws inserted into the plywood holes as there isn’t a box above it getting in the way of your fingers.

A few minutes fiddling with screws and this is the result.

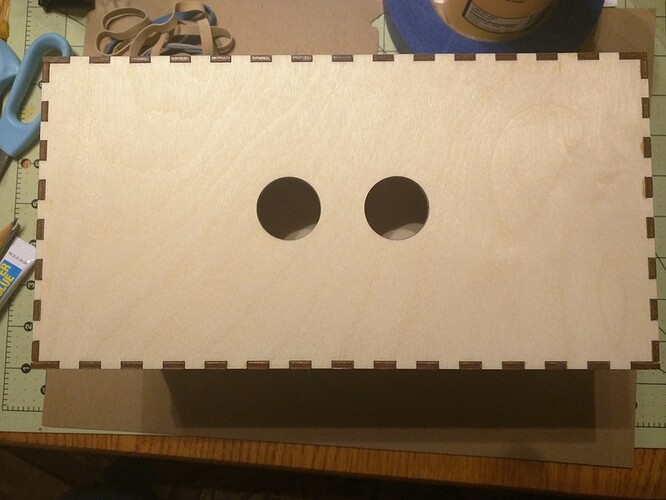

Last piece to do is the new cover I made. I measured length, height (keeping it so the top doesn’t hit the arms), width and centerline. I used Makeabox.io to create the initial box cover remembering to tell it that my measurements were inside measurements so the box will slip on over the sewing kit.

Makeabox will generate the correct finger joint design, symmetrical so there’s no worrying about which side attaches to which other one. But it’s going for a full six sided box. So after generating the PDF and dropping it into Corel I deleted the bottom. But the sides and ends had notches for the fingers to mate with the bottom. Easy enough to fix by unlocking the PDF import, ungrouping the objects and lassoing the fingers on the bottom of each side/end piece. After deleting those I extend the remaining line and joined it to the other corner leaving me with a notched top line to mate with the box top and a flat straight cut on the bottom.

“Print” it and I’ve got my pieces.

This is a little different than the design file attached because I was using up some plywood I had cut an earlier piece out of. Just tightened the spacing between the parts by moving them closer in the GFUI and rotating on of the sides before moving it to the right side of my material.

Notice I cut 2 holes in the top to be used as finger holes to take the top off easily. These can be deleted if you want a solid top as you can take the top off easily (it’s a snug but not overly tight fit) with one or two hands. I made the holes an inch in diameter as I can use my thumb and forefinger and grip the inner box end walls to carry it like a bowling ball. These can also be reduced in size for smaller finger people.

I also glued a neodymium magnet in the upper left corner of the lid. My wife drops her needles a lot (she “puts them down & someone moves them”) so she can put the needle down on the corner of the box while she’s taking a break and it will hold via the magnet underneath the lid.

Glued and held with asparagus clamps. ![]() Actually this are rubber bands that the supermarket uses around stalks if asparagus. They’re a bit thicker and stronger than normal brown office rubber bands but really stretchy too. My wife is a vegetarian and eats a lot of asparagus so I collect them. They’re perfect for clamping small boxes like this. As a point of reference this is 9 1/2" long, 4 3/4" wide and 2/3" tall.

Actually this are rubber bands that the supermarket uses around stalks if asparagus. They’re a bit thicker and stronger than normal brown office rubber bands but really stretchy too. My wife is a vegetarian and eats a lot of asparagus so I collect them. They’re perfect for clamping small boxes like this. As a point of reference this is 9 1/2" long, 4 3/4" wide and 2/3" tall.

Fully assembled here’s the sewing kit.

The SVG files are below. One, note of interest - all of the finger joints are symmetrical but I have flipped one of the top sides so it’s cut opposite the other. That will let you use the cut face as the outside face for all of the pieces. You can see on my box I had to turn a pair around which resulted in the bottom or flashback burned side being revealed. Not an issue if you mask, but if you’re a non-masker like me then it’s harder to sand that side clean (I didn’t bother sanding the backside of the other pieces in this one because it’s only my prototype).

(Not sure why the first one shows well but the other three are black boxes. If someone can download them and see if they’re good I’d appreciate it.------ Okay I figured it out. I have a box that’s 18x10.5" on my 20x12 artboard so I know what the current usable area is in the Glowforge. That doesn’t get cut as it’s on a different layer. When uploaded it shows as a solid black box. Fixed it by deleting the box and reuploading.)

This is the original file from Thingiverse.

The base & arms ready for the Glowforge.

The two layers of boxes ready for the Glowforge.

And the top:

And for those wanting a felt lining to cushion the contents, this SVG has the basic patterns needed as well as the number of each piece you’ll need. Standard self-adhesive felt from Michaels or other craft store cuts easily with the Glowforge and will stick to the box when the self-adhesive liner is removed. It’s easiest to do this after gluing but before assembling the boxes - the screw holes are part of the pattern.

And cross-posted to the Free Plans category with some additional thoughts.

And on Thingiverse: Sewing, craft or shop expanding box by DiggerJim - Thingiverse