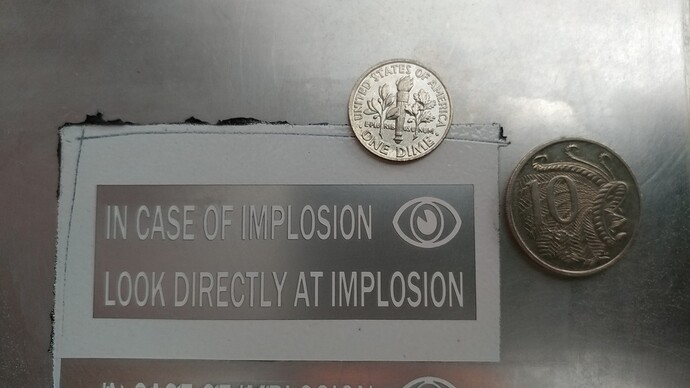

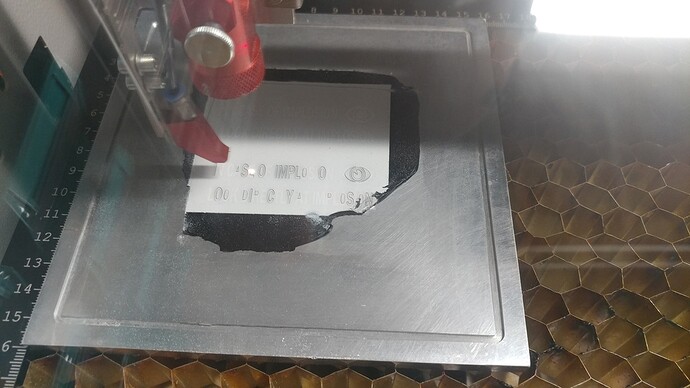

I decided to try Plasti Dip as a powder coat mask. I started with this…

And ended up with this…

I had a scrap-ish piece of aluminum that I had already milled flat. I used it to make some custom silicone gaskets a few years ago and it’s been sitting around taking up space ever since. (Very quick aside: the gaskets looked sorta OK, but I never ended up testing a single one, I got bored of the project I guess.) The plate isn’t ideal, but it was good enough to test with.

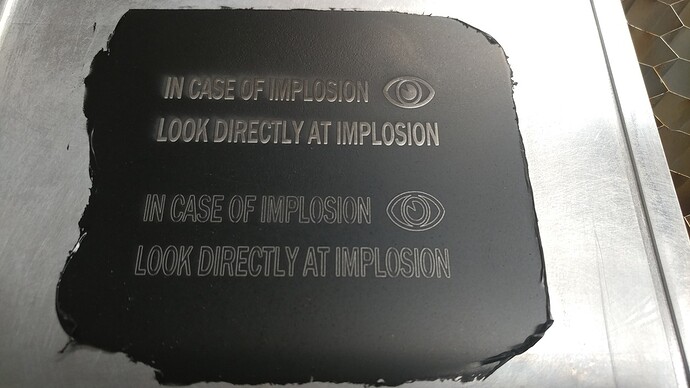

I started by spraying a couple layers of Plasti Dip onto the plate. A painter I am not, so the layers were probably pretty thick. The can recommended 3-4 layers, but I stopped after 2 because I figured that was enough, it only had to last a day or so.

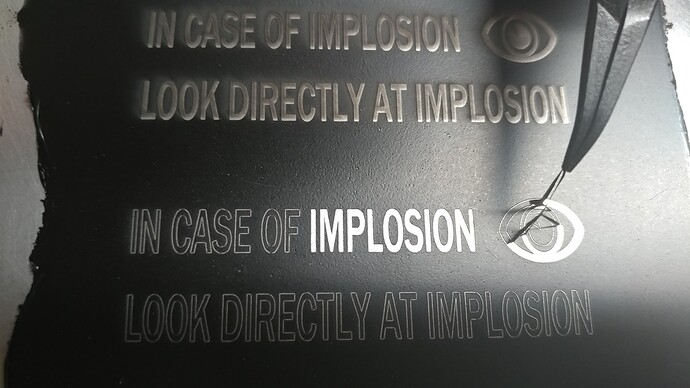

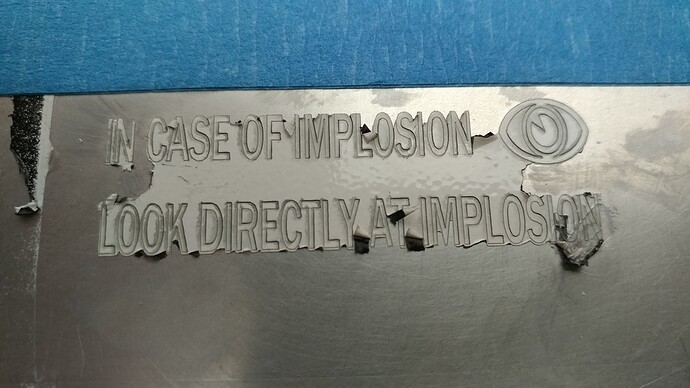

I put the plate into my laser cutter and cut the message in two different ways. I vector image raster fill through-engrave blasted one (top) and vector cut the other (bottom).

Then I weeded out the vector cut letters.

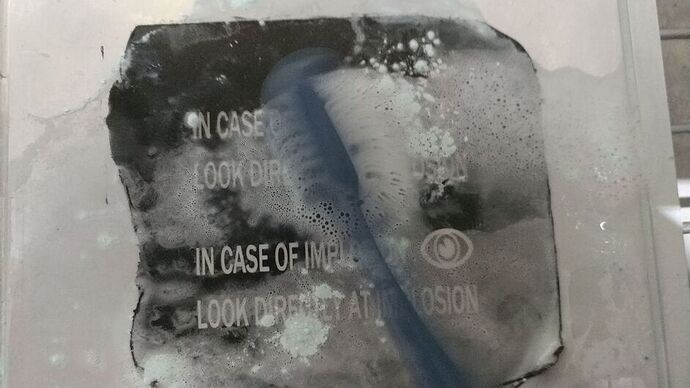

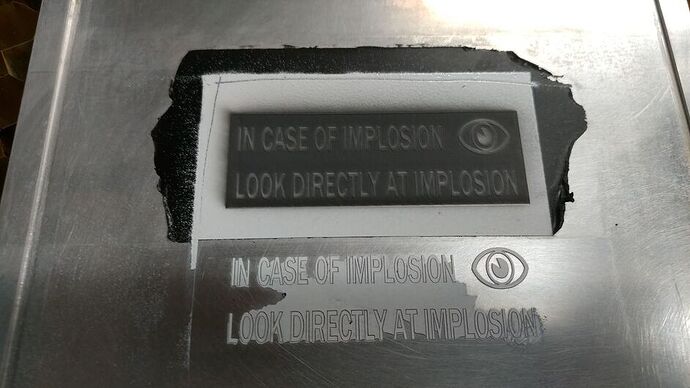

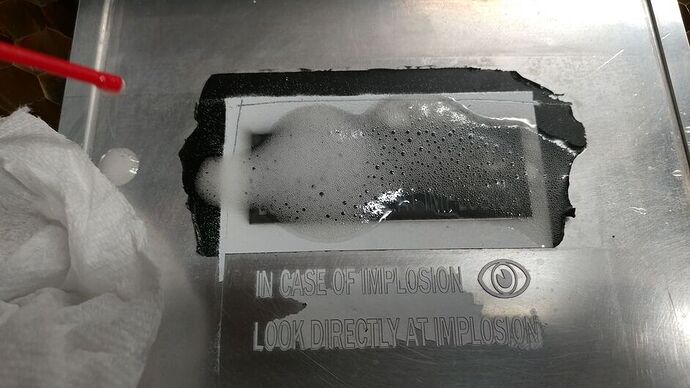

The engrave left a bunch or residue, so it needed to be cleaned up. I would have cleaned it anyway, but the residue from the engrave made it imperative. Here’s an action shot of scrubbing the letters with a tooth brush and some Comet (kitchen cleaning powder).

Next, I masked it some more and powder coated it. I wear this gas mask-lookin’ thing when I powder coat. I don’t know if it’s necessary, but it’s not really all that uncomfortable and it protects both my lungs and eyes. I’ve used other masks, but I wish I went directly to this instead of trying the couple other options beforehand.

The painter’s tape (probably) needs to be removed before it goes into the oven. Unfortunately, it was sticking pretty good to the Plasti Dip and I ended up messing up the bottom right corner a bit.

Oh well, good thing this isn’t an important. I put a couple slices in the Plasti Dip to stop that from happening again.

After baking, I put the plate back in the laser cutter to cut the letters out again. I only did the bottom one at this time.

The adhesion of the Plasti Dip went into overdrive when it was baked. It would no longer peel off easily. The stuff covered with powder coat was even worse. I tried a variety of cleaners/solvants on it, but none seemed to be able to soften up the Plasti Dip + powder coat layers. I tried isopropyl alcohol, WD-40, mineral spirits (which might have worked, but it probably would have taken off the powder coat that I wanted to keep as well), nail polish remover (acetone), Pre painting prep (from Eastwood), Simple Green, and Smith & Wesson Lubricant and Protectant. A couple of those might not have been good for the powder coat, so even if they worked I might not have wanted to use them anyway.

After all that, I was basically left with this.

No good.

Next I took a step I didn’t want to, but since I was running out of things to try, I decided to try to engrave the mask away. I tried it on the eye of the bottom one first, and then did the whole top section. The engraving basically took away the powder coat, leaving a layer of the Plasti Dip.

Thankfully, when I was testing all those chemicals (and through doing some internet searching) I found that WD-40 basically melts the Plasti Dip on contact. It’s also supposedly OK to use on powder coat. So I sprayed some on.

And wiped it off - this is just a single wipe very shortly after spraying the WD-40 (maybe 15 seconds later).

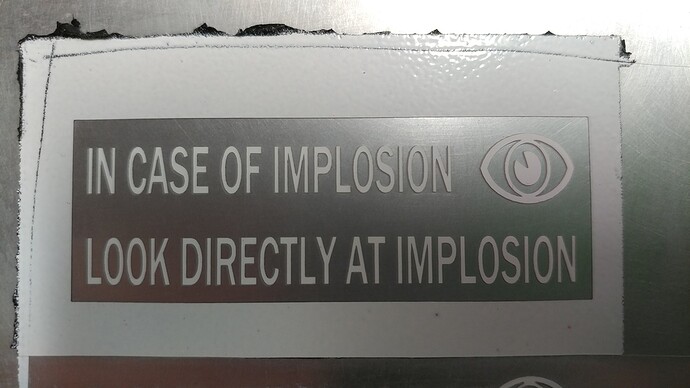

I gave it one more WD-40 bath and then a final scrub-down with the toothbrush and Comet. This is the end result.

Not too shabby, if you ask me.

And here’s a couple super-macro shots of the eye.

And, since I like to complain and since my soul is black and I’m a troll and who knows what else people might think (or maybe because I’d like problems to be solved instead of ignored): there seems to be some kind of residue left over on the aluminum. It’s most apparent in the macro shots. It seems to mostly be below and to the left of the powder coat, but the direction it’s in in relation to the powder coat isn’t consistent. I don’t know what it’s from, but it’s worth looking into. Those marks might just be from the way I dried the plate after the final cleaning - I used an air hose and blew it off. Those light areas might just be places where there was a little bit of Comet left over, and it dried there instead of being blown away. (nope, I cleaned it again and the marks are still there and look exactly the same) I dunno.

Thanks to @mad_macs (for starting this thread), @jkopel (for the Plasticote recommendation, even though it didn’t actually register with me the first time around), @kids_a_pistol (for starting a Plasti Dip thread that I’ll link to below, and @cynd11 (for checking the Plasti Dip FAQ and finding that it doesn’t have PVC).