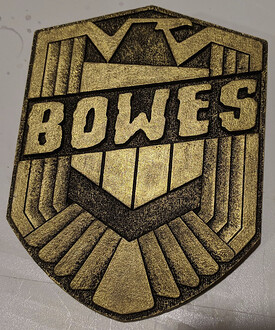

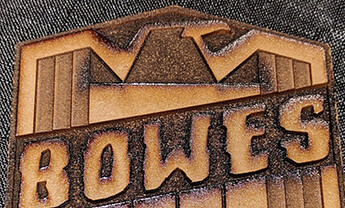

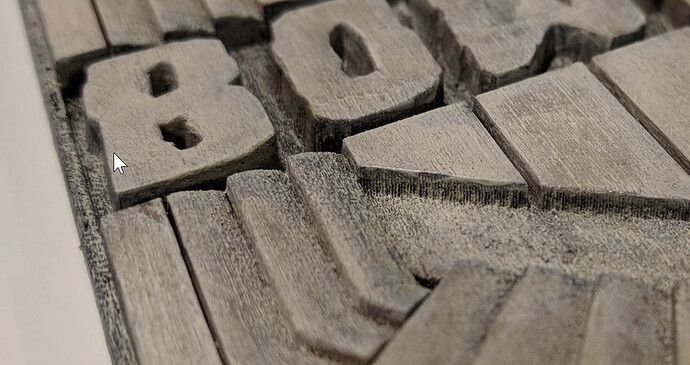

I have experimented with 3d engraves on a few materials now, and compared Proofgrade and manual “vary power” modes. I’ll put my findings below, but first, pics of a finished project. This is a replica of a Judge badge from Dredd (2012).

Judge Badge in Draftboard

Manual 3d engrave, 500 speed, Full power (Pro) (Maximum engrave depth .062")

Surface prep: 1 coat Golden GAC100 size, 1 coat Jack Richeson white gesso, 400 grit sandpaper before size and after gesso

Paint: Craftsmart Classic Gold followed by a black wash (easy as falling off a log, honest)

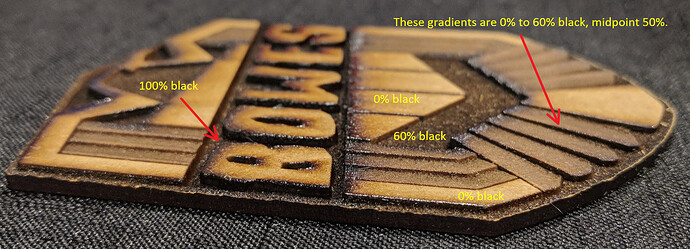

File: PNG with the deepest parts set to 100% black, mid-depth 60% black, and each sloped surface a gradient from 0% - 60%.

(You can see what the originals look like here. They were cast from metal… I’m not there yet.)

Comparison of Proofgrade and Manual 3d Engraves

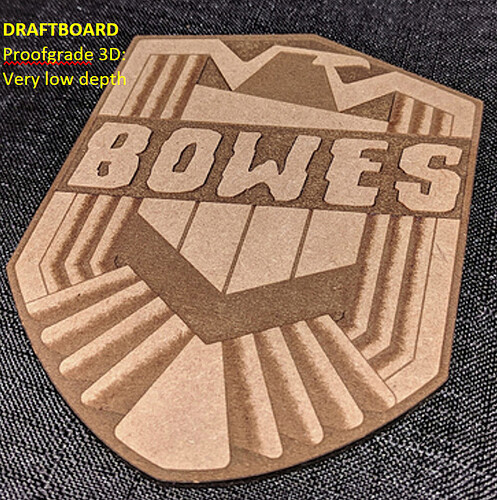

Bottom line, Proofgrade’s 3d Engrave mode does not go for depth, and it does appear to lower the contrast. If you want to make your Glowforge stand in for a CNC mill, you need to use the “vary power” Manual setting.

Draftboard, Manual 3d Engrave

Draftboard, Proofgrade 3d Engrave

Comparison of Draftboard, Basswood, and Poplar 3D Engraves

Draftboard produces a somewhat decent 3d carve, but it makes a LOT of char and sticky goop. I could not get it all off with alcohol or sanding. I painted over sticky spots and hoped for the best. It worked out, though.

When painting over the goop with size, I got a lot of brown discoloration as the size soaked up the goop and char and spread it around.

The finished item above was made from Draftboard, so it is serviceable, but basswood and poplar both are much nicer to work with.

Poplar produces much less char and goop than Draftboard. This is a closeup of 1/2" poplar, carved at speed 500 and Full power – 2 passes. There is about 0.19" of depth to this carve, and it came out pretty clean. This piece also has 1 coat of size and a couple coats of gesso on it, and it was sanded with 400 grit for initial prep and in between coats of gesso. (BTW, my Pro cuts 1/2" poplar at speed 145, Full power, 2 passes.)

Basswood is even better to carve than poplar. It carves more easily, produces less char, almost no goop, and produces a slightly less textured surface on those deep, crispy areas. Here’s the basswood version, also with size and gesso appliled. It is hard to tell from the photos, but I think the quality of the carving and residual texture is definitely a bit superior to the poplar.

(I did not try 2 passes on basswood, but I don’t see why you couldn’t do that and get a deeper carve if desired.)

One more picture, of the 3 unfinished pieces. The thick one is poplar (done at 2 passes for more depth), the skunky lower left is Draftboard, and the lower right is basswood.

And, here is a photo of the pieces with the gold base coat applied.

There is no hiding that these are made out of wood, but the laser texture sort of, kind of looks like sandcasting texture, which isn’t terrible for this item. Still, it will take a lot of work and maybe some different sealers to turn carved wood into a smooth, plastic-like surface… If it is even possible. If someone has cracked that code, please post!

tl;dr basswood ftw