It’s been a wild month! To start with the most important topic: our schedule (here) is unchanged, and we continue to deliver units of ever improving quality to our testing partners, folks like you, and a few famous customers.

In fact, every review of Glowforge to date has been by a paying Glowforge customer, including the latest by Matt Stultz, the 3D printing editor for Make Magazine:

[The Glowforge Is Almost Here and it’s Worth the Wait]

(The Glowforge Is Almost Here and it’s Worth the Wait - Make:)

and Bob from from I Like To Make Stuff (@iliketomakestuff on the forums):

At some point we’ll have press units out for review, but right now, the only folks receiving Glowforge deliveries are preorder customers like you.

Meanwhile at the office, it feels like we’ve turned a corner. This month we put an end to our most sticky problems - a batch of bad tubes that was’t able to engrave well, a bug that was causing the machine to reboot occasionally during prints, and a supplier problem with a linear system component that was causing wobbly engraves.

There’s also piles of work that just keep things out of your way. We’ve fleshed out our suite of tests that let us spot hardware problems sooner - identify subtle defects when parts arrive, and spot a wider variety of problems at final inspection. Our web service logged 4 9’s of uptime (99.997% available) last month. Boring stuff, but things that we worry about so you won’t need to.

There’s a lot more, but if you don’t have time to read through everything, let me suggest this resource:

Best of the Glowforge Community: Weekly Highlights

Our community curates some of the most interesting highlights from posts each week, including examples of what Glowforge units in the field are printing, details about process, and cool design ideas. It’s a great way to binge on a bunch of Glowforge info & get up to speed on the best of the latest.

Finally, I have a story to share. I was at a small conference last weekend in Chicago. Glowforge customer Max Temkin lives close by, so I asked him to bring his prerelease unit from his office (Cards Against Humanity) to share. Folks were printing cool stuff all weekend, but something happened that made me so happy I had to share it with all of you. (Please excuse the terrible video quality, as it was noisy and I was just recording tidbits on my phone.)

One of the conference attendees, Liz, had recently decided to learn viola and brought her new instrument to the conference. Someone at the airport was careless with it, and the bridge - the portion of the instrument that separates the strings, and holds them away from the main body - snapped in half.

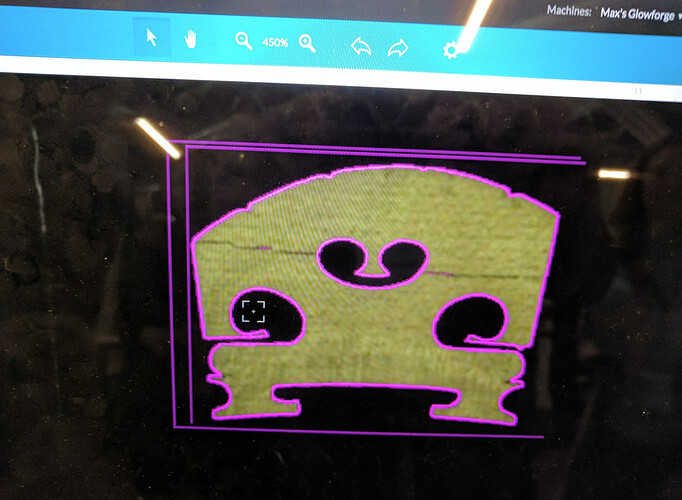

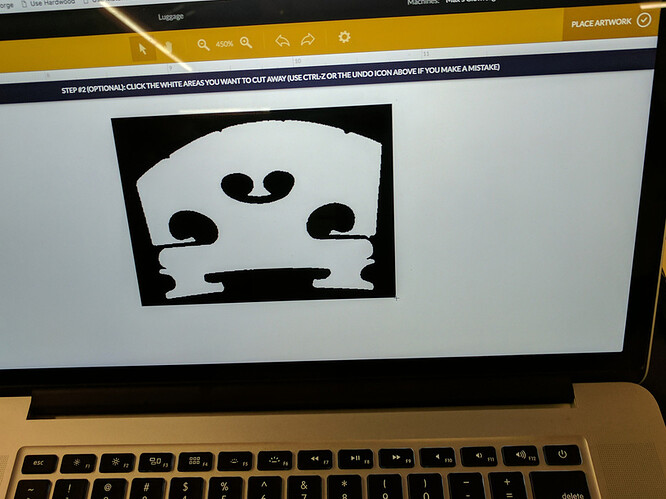

I didn’t know Liz at the time but saw she looked upset, and we asked if there was anything we could do. As luck would have it, the bridge was maple, and we had Proofgrade maple on hand. We decided to try using the Trace function of the Glowforge to see if we could reproduce the bridge - a tricky matter, since both the top and the feet had to curve at precisely the right angle. We carefully pressed the split halves together, set it on the bed of the Glowforge, closed the lid, and clicked “Trace”.

Then we put in some maple and asked Liz to hit the button.

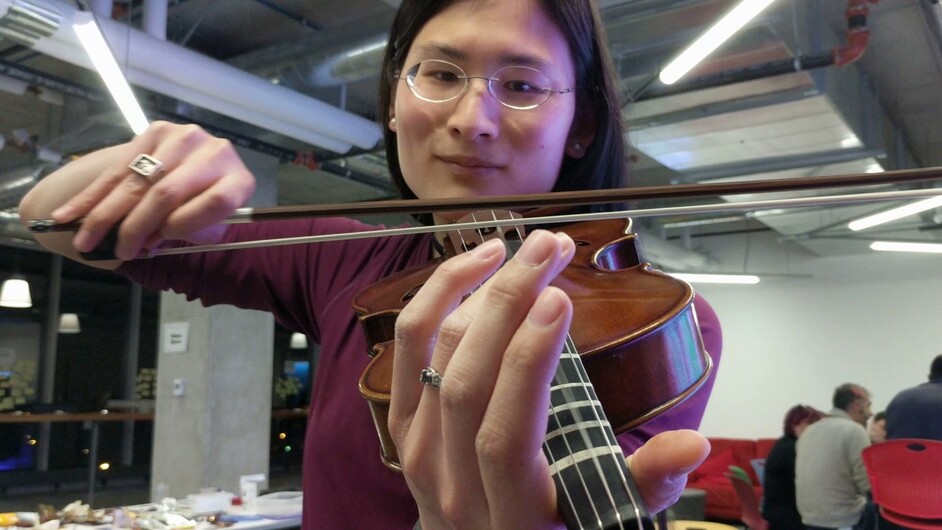

It took some fussing to get the new bridge into place. A small crowd had formed, watching as she gently nudged it into place and started tuning.

Finally, she got to try it out.

I cannot tell you how excited we all were. The whole process took just a few minutes, from start to finish. Her musical instrument was whole again.

This is what we come to work for every day - to give you this magical superpower. To make things. Beautiful things, practical things, wonderful things!

Thank you as always for your patience. We’re working long hours to make sure your we meet our schedule for you, and that your machine is as great as you deserve.

We can’t wait to ship you your Glowforge.