I made mine out of scraps of maple hardwood, work fine but eventually break off at the top - not a flaw, just wrong material!

Or maybe wrong grain orientation… If you made the grain go “lengthwise”, meaning along the length of the pin, it’d probably hold up pretty well.

That being said a plywood or MDF could be a better bet probably.

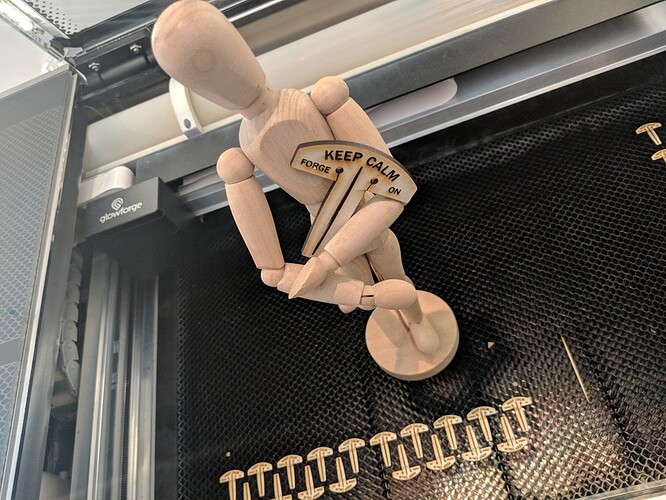

Bada BING!

One warped piece of wood, so I cut a pile of these fantastic pins out of scraps.

I’m finding it is better than my ex-hard drive magnets. Like, by a long way.

Brilliant. I love them.

I’ll send all my friends here for a free cut file, and thanks much @eljefe4.

Thank you for the file for these. I just cut some out and they work awesome. Much appreciated.

Thank you for these! One of the first things I cut with my new Pro unit and have used them for every cut since!

hahaha… love it!

(i have a few of those figures kicking around also… need to laser a face on him…hmmmm i think Ill do that!

thanks for the smile!

Thanks for posting this @eljefe4! I just made them out of .188" plywood from Home Depot ($10.98 for a 4’x8’ sheet). It was our first test with that material. A speed of 225 turned out to be the best.

Perfect - thanks

And no one but me is worried about the strain on the honeycomb? I must be being paranoid, but it just seems like the honeycomb wasn’t designed to withstand forces in that direction – it’s strong and level, but I would imagine if you jam something in there tightly enough, you’ll bend it out of true comparatively easily.

I’m probably wrong, I should just get over it.

Edit: I was wrong and am now over it. I use pins regularly.

hey there… with an expensive delicate toy like Glowforge, I can understand your concerns. i have owned a laser cutter/engraver for about 12 years and the honeycomb is far more delicate on my other unit,

then this monster… im assuming that the GF bed is made of steel and my other is made of far thinner aluminum (could never use magnets). I had originally made my hold downs by way of 3d printing and they were rounded. Those babies worked great but put far more strain on the pattern then these do. I intended to just make new ones for GF with the same design but found the pattern to be FAR more irregular on GF and thus, wanted something that had some spring to it… I also wanted to design something that the community could just make with the tool at hand. some might not have 3d printing capability.

While i can certainly not guarantee that these will not deform the bed (someone might make them too big or out of harder material) I can tell you that i have zero concern on this and also, intentionally made them “fusable” so that they will break apart, WAY before the steel deforms … if they feel too tight and you have to shove them in with more then slight pressure, scale them down a bit and get a sweet fit. your bed pattern might vary from mine… there is definitely variation in the pattern. if you have any ideas of other questions, feel free to private message me…

cheers

JJ

I worried about that. But since I started using them last week I can’t live without them.

I have to say thank you again. I started working with non-proofgrade materials and some of the ply I’m using is curved. These babies hold it down tight and I could NOT use the GF with out them. I haven’t seen any noticeable effect on the crumb tray.

They work great for curled linoleum, too.

Thank you. These work so well.

These are great!!

I’m adapting them to be bottom pins in my pegboard designs. They fit well into standard 1" in center pegpboard.

Big thanks for these. I cut a bunch of them out of scrap board, and all of my cuts have been better since. I used these pins and box of Zeiss lens wipes to “stack the deck” for everything now.

Had to use something beside magnets and remembered this.

Nice job. Worked swell with 0.20 scraps.