im sorry, I just took it out of the cutter. I can lign the material up again tho. I always put it up against the bottom edge of the tray and the ruler wasn’t moved.

So sorry to see this. My alignment is also all over the road, and most of the responses I have seem to think it’s because I can’t use calipers. I wrote to support and got the stock useless response. Currently I am trying to make a file as described here: Lid Camera Alignment Examples FTW but the sad thing is my alignment is so off (but you know, totally within acceptable tolerances) that I’m not even sure how to set up the file with the wood to line it up.

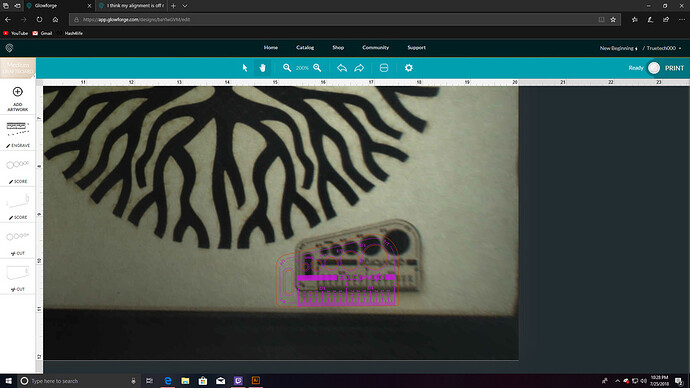

see, that is exactly what I mean, his IS actually a satisfying alignment. Dont get me wrong, I love this machine, but I feel that I deserve an available fix for this rather than people telling me that I AM IN THE WRONG!!! look at mine vs his! it is pretty clear it is not even close.

One of the things I really don’t like about this forum is that it’s always the fault of the user. Plenty of times it is user error. Heck, it’s often my fault, and I appreciate being corrected, but I hate posting things here because of this reason. I have a friend over today hoping to engrave on some cut wood. It’s not proofgrade. Too bad for me.

Yeah, I know that it is technicaly "Within accuracy " with yours but seeing as the guy in your link has that as his margin of alignment, we are not able to use it like this. what you show here Has alignment changed in a recent update? is not ok! if is really a software issue then stop working on glowforge app on IOS and adding features and fix the alignment issues so that people like us can actually use their machine. it is near impossible to do anything worth doing with this the way it is! Our warranty clock is ticking! Step up Glowforge and help your customers.

I’m frustrated too, I get it. My machine is just grinding in the corner now, after all the artwork I spent an hour on disappeared and I rebooted.

how is it fair that our warranty is going down and we are unable to use our machine! not because we dont have anything to print but because we genuinely have a problem that is being blamed on us.

Keep writing to support, I feel the same way. It is an unreliable machine, and I really hope someone helps us both out.

I can’t even sell mine - as it straight up doesn’t work. It’s not a question of I don’t want it anymore. If support can help me make it work reliably, I’ll be thrilled, but if they can’t, I would really like a full refund.

I am sorry to hear about the grinding btw. I am not saying it is un reliable but I do think that if a thing like this is fixable then it should be quite a bit higher than an app. this makes it un useable. I love this machine and generally love this forum and all on it but we should not be blamed for an issue we have even with proofgrade.

I mean to say my unit is totally unreliable. Ideally I’d like it to turn on, not grind, and be predictable in the positions where things are printed. This must be working for a lot of people, just not for me.

yours seems well away from normal. I would assume that GF is going to have you send your machine in. also, I was wondering, is your alignment getting worse and worse or is it off by the same amount each time?

It appears to be random. When I sat down to do some tests and really nail it down today it started grinding. That said, the first week I had the machine it worked much better.

Feels bad man. In my opinion, the solution to my issue with alignment would be that the release a calibration tool that lets you line up 4 corners with the corners of a piece of proofgrade draftboard or any 12x20 piece of material and the bases the fish eye fixing algorithm off of the location of the corners you place.

The majority of the first advice you’re going to receive on any issue is steps that you can use to diagnose the issue further or potentially fix the issue.

Most of the time, the initial post of a problem is very limited in information.

That’s going to be the same from Support or from just regular users.

No one has a clue to what anyone’s knowledge is about the machine. No one has a clue to your technical aptitude.

Some things aren’t EUE, a lot of things are.

or even better have us place the corners up to the corners of our tray so that we dont need a piece of material to do it.

Yup, there are lots of variables, but IMO this forum is unique (and not in a good way) in the manner that people with problems are piled on.

because if it knows what the size of the tray of the machine is and we place the corners where we “SEE” the corners of it at then it should be able to calculate where to base our print area.

I’d be happy with a workflow that includes a step with a beam of light that shows the center of your design, like a zero toolhead feature. It’s possible to do this with a low power pass but the workflow is really slow to do this way.