Hey everyone! I’m new to the forum, but I’ve been getting my weekly dose of inspiration from all of the projects people have been posting through my Glowforge forum digest email. I wanted to share a recent project with you that isn’t entirely “laser made,” but rather “laser-assisted.” I’m a bit of a beginner when it comes to woodworking, but I often use a laser cutter to create templates for the more complex elements. I guess first I’ll show you the jewelry box and then explain my process. The materials were walnut, oak, and marble.

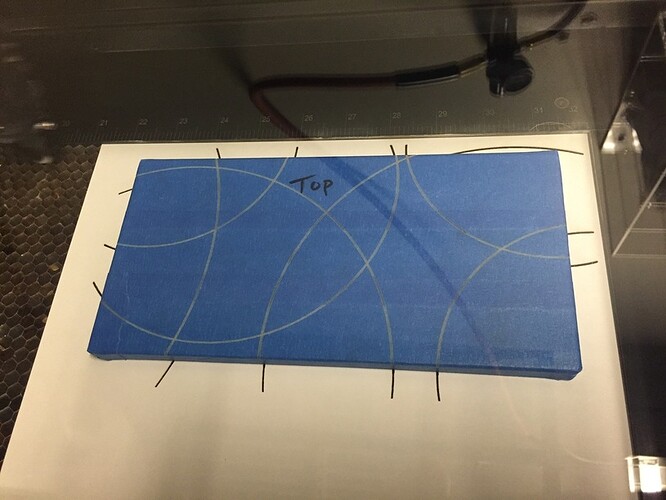

The marble is a $4 tile I purchased from Amazon (link). I had it cut to size for free at Lowe’s and then I shaped and polished it with a lot of sanding. I wanted a gold pattern on the lid, so I came up with a design I liked, masked the tile in painter’s tape, and let the laser do the heavy lifting. I etched 2 passes (100% power, 50% speed), which didn’t go as deep as I would have preferred, but it was sufficient to get the job done.

At this point, I wiped out the etched lines to clean out any residual marble dust and sprayed a couple of light coats of primer before applying two coats of gold spray paint. Once dry, I carefully peeled off the painter’s tape and applied about 5 light coats of clear spray polyurethane to help protect the gold from getting scratched off.

The other detail that was templated with a laser was the cutout on the top of the box. I drew the pattern and laser cut it from scrap 1/4" plywood. I used double-sided tape to adhere it to the panel, rough cut the majority of the waste with a fret saw, and then used a flush trim bit on my router to trace the pattern perfectly into the walnut.

I use this technique quite a lot to make more complex shapes in material that’s too thick to directly laser cut, particularly when I need repeatable parts. The sides of the beer caddy and litter box bench below were done this way. If the shape is too big for the bed, I simply split it into multiple templates which I connect after the fact.

I’m not great at photographically documenting the process, but I’d be happy to provide more details, templates, etc. Anyone else do laser-assisted manufacturing?

Thanks,

Prem

http://www.premblog.com

It’s far from an original use of the tool. I haven’t yet explored the forums in depth, but I’m excited to see what others are doing in the realm of clever laser cut jigs and templates that don’t get directly used in the final product.

It’s far from an original use of the tool. I haven’t yet explored the forums in depth, but I’m excited to see what others are doing in the realm of clever laser cut jigs and templates that don’t get directly used in the final product.