I tried searching a few keywords, but couldn’t find anything specifically illustrating the glowforge enclosed pathway for the laser that I had heard several people call out as a feature. How is it enclosed from tube all the way to the head? Head is removable. Where are dust seals and alignment fixed points?

Searched for @Dan enclosed path

It lacks your details but for better or worse that’s the ![]() way.

way.

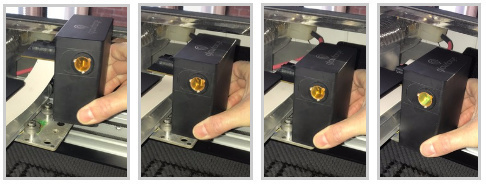

The path is open to the head, but the corner mirrors and head mirror/lens are enclosed behind windows. The windows can easily be cleaned if necessary whereas first surface mirrors could more easily be scratched. Since you don’t touch the mirrors re-alignment is not necessary. Here is a pic of the head being installed. Notice the round window.

Here’s the scoop:

- Beam exits the glass laser tube through an expensive bit called the Output Coupler (a partially-reflective window). It’s permanently welded to the laser, so it’s important to keep it clean.

- Beam emerges in a custom molded plastic tube with an airtight seal that protects the output coupler.

- Beam enters the solid machined aluminum turning block.

- Beam hits two delicate first-surface mirrors, making a U-turn.

- Beam exits the machined block through a laser-transparent window.

(this is the only point at which the beam is exposed) - Beam enters the head through another laser-transparent window.

- Beam goes through its beaming magic in the head, with another first surface mirror, autofocus, and the like.

- Beam exits head, along with a tiny stream of air to keep nasty stuff out

- Beam makes cool things for you!

We think this is a huge improvement over the standard arrangement with a bare output coupler and turning mirrors that are directly in line with the flow of exhaust.

Only bit I followed out of that was the last one. ROFL!

That one sounds real good though.

Thanks, Far more details here than we have seen. Since you had been so enthusiastic, but guarded, about that part of the design, I could only hope the full path between the laser and the last corner mirror was sealed. Didn’t know how to not say it correctly.

A fancy way of saying the beam is fully enclosed, and sealed from dust/debris, all the way from the laser tube to the very last corner mirror on the left side. The beam is exposed only between that mirror and the little round window on the head. And of course where it comes out of the head toward the material.

I experience it as fully enclosed, meaning that as I look at it I see a tube and the head where the beam hits the material. It’s like a garden hose. You only think about the two ends unless you notice a leak. All the links and folding don’t register because the water just comes out. That’s pretty interesting to me.

Brilliant design!!

Leading into a follow up question on where the laser tube ends (for replacement) and the rest of the u-shape beam redirection assembly are interfaced together… how are they sealed in some way as well?

Yes, with a custom molded coupler.