yes and yes

I unfortunately cannot run the calibration  . Machine is in a ready state, I begin calibration. It says it’s centering. Then the machine says it goes offline. The physical machine has the bar even with the lid camera and the laser head moved all the way to the left. It’s done this to me several times.

. Machine is in a ready state, I begin calibration. It says it’s centering. Then the machine says it goes offline. The physical machine has the bar even with the lid camera and the laser head moved all the way to the left. It’s done this to me several times.

@Cole looking at the logs for your Glowforge, this may be a WiFi connectivity issue. Can you try turning your Glowforge of then turning your router / access point off and back on again, then turning your Glowforge back on and try again?

Thanks for burning the midnight oil  . That worked.

. That worked.

Looks to me like the head got bumped. That much off is a classic sign. If it were me I would power cycle the machine and then check the calibration again with the target graphic. You might not need to redo the lid camera calibration.

Were you getting an error that said “The process was interrupted, so no changes were made to your calibration” while it was trying to take a picture?

I’ve run it three times now and still failing each time on that step. Wondering if I should give it another go after clearing the cache, cookies, etc.

Omgomgomg I loooooovvve this feature! Camera alignment is now virtually spot on. This is going to save me soooo much time, which is something I do not have much of. This made the machine go from ‘cool’ to ‘awesome’!

Guess I better order some draftboard. I never use it, so I don’t have any, and not sure I want to burn a whole sheet of acrylic here…

No, I wasn’t getting any errors at all. Just the misalignment of the target vs the burn on the wood after it was complete. Honestly, if you FULLY shut down your computer (full 30 seconds at least, to clear the memory) and pull the power on the glowforge for 30 seconds… That MIGHT help you. Shot in the dark, I don’t really know. But I’m in IT and shutting anything down for 30 seconds or more usually clears up quite a few issues.

When I worked in IT that fixed a lot of stuff for me. If all else failed, as a last resort I’d stick it in the big XL diesel Ford company van they gave me to drive, and just drive around with it for a day or so, and then try it again. That almost always worked! ![]()

If you have a 20x12 piece of 1/8" ply that should work too. If it’s not light colored you probably want to mask it too.

Any super flat material…

Genius. It’s amazing the things we do for tech. I had a laptop that would only boot if you popped it in the freezer for at least five minutes.

The laptop was probably using that as an excuse to eat your ice cream without your consent. Sneaky little buggers…

There is a lot of communication going on between the GF and the cloud for this process. Whereas on a normal print the unit uploads a lid image and the design, and receives a motion file, the majority of normal print operations can be performed if the connection is dropped after the motion file is received. I’m thinking this calibration process needs a far more stable and consistent connection. In addition to the printing of many fiducial marks the head camera needs to move to, locate and measure each of these marks. I suspect that the connection needs to be stable through the entire process. Support would likely be able to check the logs to see if this was a problem. Just guessing of course.

Ran the recalibration, And while I can now see further to the left of the workspace than I could before, the alignment is way off (over 1/4 inch after recalibration). Prior to this my alignment was off by about 1/8th of an inch (which is why the snapmarks were so sweet, since I had no alignment issues with those). Never bumped the GF or touched the head or carriage prior to, during or after calibration.

Looks like it was a big failure for me. Can’t say this is any better, probably worse. I’ll try to run the calibration again but…

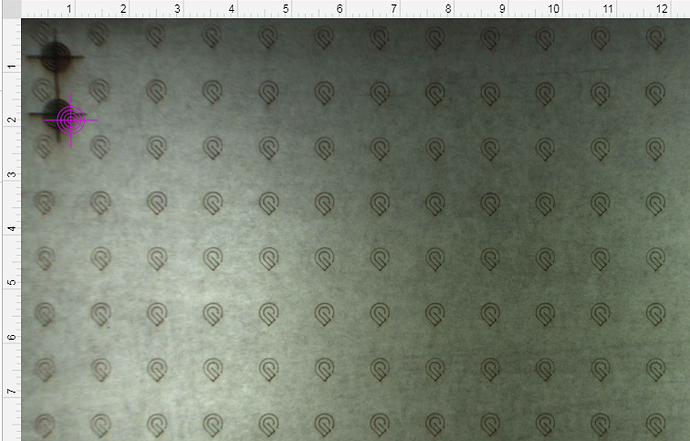

Here’s a shot of the first score to check the calibration.

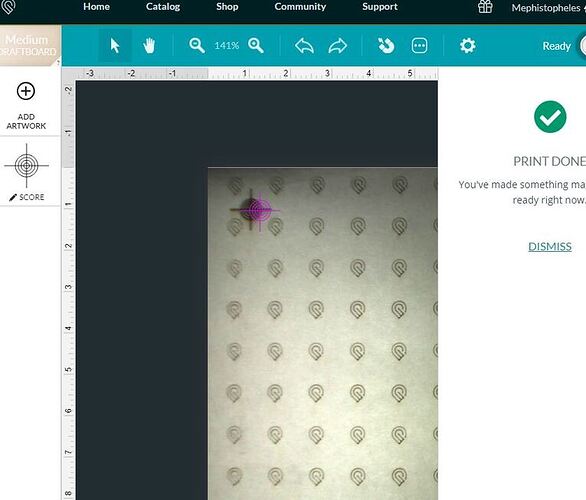

here’s a shot prescore on the 2nd try

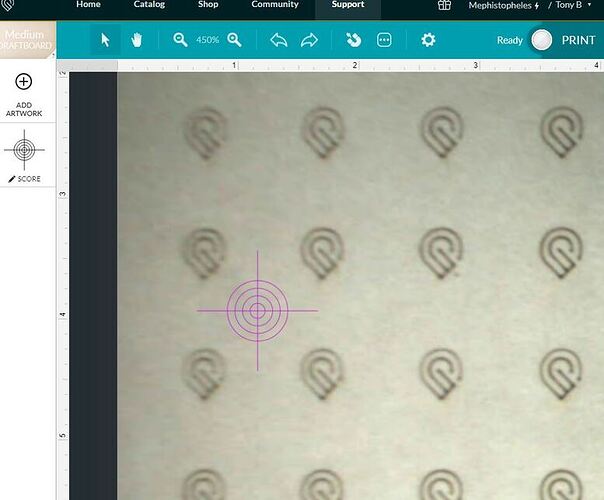

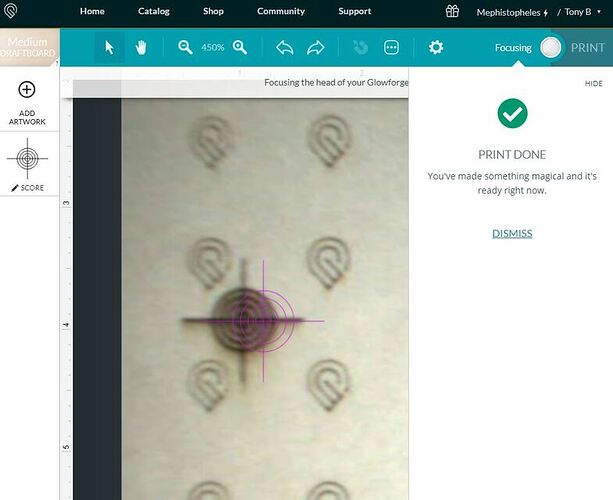

and after the score and screen refresh…

![]()

Edit: after removing the Draftboard to turn it over for a second try at calibration I noticed the board was not flat. It had the very slightest warp to it.

I’m running another attempt on a new piece that I verified is flat.

If the second try doesn’t work how do I revert to the original? I am not seeing that.

Ah yes, the fresh air cure.

Agreed. That’s usually my standard response to people when they’re having issues too (and one I should have thought of). I just hate doing it since I’m one of those 40+ tabs open people.