Thanks! I tried it and it’s working perfectly again now. Great glue!

I bought the PC7 on Amazon but it didn’t work for me. Can someone share a pic of the correct one? Thanks!

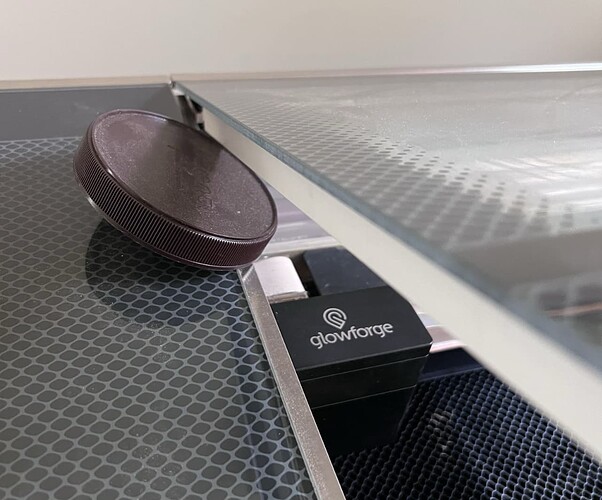

If you buy the new hing bracket you will never need to repair it again. Check the reviews on it.New GLOWFORGE Aftermarket LID Hinge Repair Bracket, All Metal Construction | eBay

Hmm, The surfaces have to be clean, and you have to be careful not to squeeze all of the epoxy out between the surfaces.

You can order a bracket that repairs the hinge permanently.

http://www.sentecheas.com/pdf/Glowforge_Lid_Repair_Instructions.pdf

Thanks for the likes

Here is my solution: Lid Saver Clips

For everyone whose lid is still attached (mine is) maybe it’s time to use my lid hinge and lid wire saving technique. I never full open the top lid. Only to clean the lenses. All the jobs that I load go thru the front flap door. It is dead easy to just lift the top lid enough to open the front, and slide the work in and out. It has the bonus of positioning items directly under the camera for extra accurate alignments.

Makes good sense, but wouldn’t work for me. The front drop down door on my dear almost-8-year-old machine falls off when you open it…so, I just don’t touch it. ![]()

![]()

No lid problems here - 4.5 years in.

I rarely open the lid all the way, I just open it partway most of the time.

I just joined the Lid Separation club. ![]() I’m also from the original crowdfunding group, so it’s been a while. I guess I’ll get some PC-7 and follow @PrintToLaser guidance and see how it goes.

I’m also from the original crowdfunding group, so it’s been a while. I guess I’ll get some PC-7 and follow @PrintToLaser guidance and see how it goes.

I’m surprised that GF won’t take your money and do the repair or replacement work. Ended up using this as an excuse to buy the new GF Pro HD. I’ll repair this one and use it as a backup and extra capacity.

I would love to hear your review of the model.

I decided to buy the bracket on eBay. Since the machine is from the first batches produced, it’s a bit of an antique and the bracket seems lower maintenance and I’m less worried about messing with the unit. My concern with the bracket is the possibility of torquing the lid and breaking the glass. The glue is a convenient give way point before the glass breaks.

The reason that my glue broke in the first place is that I had my holding pins container top (a Talenti Gelato lid) on the side glass and it slid under the top as I was closing it. The leverage was enough to break the glue adhesion without much extra pressure from me.

NOTE: Don’t put things on the side glass.

They do?

Maybe not for lids, but replacement machines are frequently the offered solution to a repair issue.

Plus they just announced last month a independent repair facility.

Yes. Of course. My comment was specific to this lid separation specific issue. I’ve been with Glowforge since 2015. Years ago, I had to send my device in for service when the lid ribbon cable proved to be too short and was damaged on the hinge area. I’m sure that they swapped the unit.

My original unit from the crowdfunding era has also just snapped from the hinge as several people above. I was able to get the ribbon back in place so it is functioning but oh my word how scary. Now off to find some PC-7 adhesive…

okay a little in the game here as my machine has begun to do the same starting from the right side. The left is still intact, however it concerns me as it seems that the glass itself is taking the load stress when we open and close the lid. I hope the glass portion of the lid will stay intact. Gonna look into that pc-7. I’m glad I found it now before I go full production again for the holidays.

Well, here I am again, about 18 months since the first(right-hand) hinge failed.

All has been well, but now the left-hand one has parted company with the glass lid.

Ho hum - at least I’ve been here, done that !

But I’d like to raise a new(?) idea. While the lid is off, I tried moving the hinges. They are incredibly stiff, probably to help keep the lid in a raised position when open, but it occurred to me that a modicum of lubrication might not come amiss.

Any thoughts, good people ? I thought a little wd40 via a cotton bud might do the trick.

What thinkest thou ?

OK, so my language reflects the 86 yo that I’ve evolved into !

John

I gave this much consideration in the past.

I relate it to a hood on a car, for example. The hinge is free to move, the support is provided either by a fixed post, or pneumatic cylinder.

The hinge itself would be a horrible way to support that weight - but that’s what we’ve got. So any time I need my lid to stay open, I use a support - a ruler, a scrap of material, whatever is handy. I’ve never lubed the hinges, but I’d choose a graphie spray myself. Anything else would attract/hold on to vaporized material.

I’ve just completed the repair, and so far perfect. I did wipe some wd40 onto both the metal pin and the sides of the plastic part, that is rubbing on a metal plate below each hinge.

It does seem to have reduced the ‘starting friction’ when lifting the lid, so I think it’s a definite improvement. Certainly makes me less nervous when opening Goldfinger !

John