Very sweet…she’s adorable! Please tell her I love the earrings she designed and printed.

You are much better at writing up the details! Here is hoping @Hirudin get’s his Glowforge soon.

It was a bunch of fun! We must do it again sometime.

Hahah… thanks! I won’t say I’ve been writing this up the entire time I’ve been back, but that isn’t far from the case.  Apparently a very nice pair of earrings were designed and “printed” in that same amount of time.

Apparently a very nice pair of earrings were designed and “printed” in that same amount of time.

Here’s a post I put up to talk about that “in case of implosion” (hey! also from Portal!) thing that I made with plastidip…

I like long posts, especially filled with details and illustrations. More please!

I’ve had success cutting .43" acrylic. I use a lower power and I think around 15 IPM and two passes.

Nice to highlight the relief cuts. I forget about those.

Please tell her that the earrings are outstanding.

Zow! You waste no, and I mean no time! I can see the talent runs in the family. My regards to your daughter; she has a bright future ahead in design.

Really surprised that you didn’t! That’s not a pot shot, you just come off as very analytical or organized. I would’ve imagined you going in with a long and detailed list in order to put the machine through its paces!

Not overly so, you had good info in there. I appreciate your insight and your honest review, given that you’re an experienced laser user and (at times) a vocal critic. Seems like you were pretty candid about the machine’s shortcomings as well as your own design and planning errors. At the end of the day, how do you feel about it? Is it of the quality that you were expecting given the price point, marketing, wait, etc?

And kudos to @chevalier_jeanpaul - it was kind of you to open your home to another forum member so that they could experience this!

You know, I’m a bit surprised by that myself.  I think the main reasons I didn’t is because I was trying to go into it with an open mind and also because I was checking out someone’s personal machine… I think it would be pretty rude to be like “thanks for inviting me over to your home so that I can nitpick the machine you bought”.

I think the main reasons I didn’t is because I was trying to go into it with an open mind and also because I was checking out someone’s personal machine… I think it would be pretty rude to be like “thanks for inviting me over to your home so that I can nitpick the machine you bought”.

By and large I was impressed by the Glowforge. I’ll come back to this thread and expand on this when I have a chance.

It is good that it can cut that deep in acrylic. It makes me think 1/2" depth 3D parts should be possible, rather than just 1/4".

Very good point!

Or even create a new one, so that you don’t steal @chevalier_jeanpaul’s thunder ![]()

Looks like @chevalier_jeanpaul and his family are making more than enough thunder to go around, right off the bat!

Just incase it is not obvious, we are having a great time!

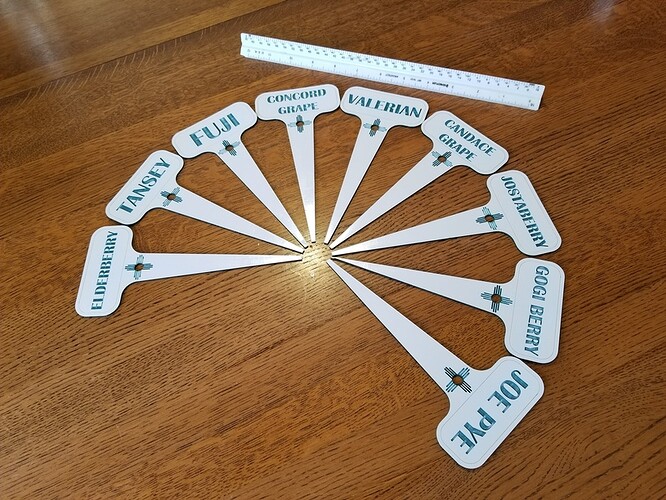

Not much time to play today. The one project I did complete was some garden labels my mother requested. I wanted a reason to play with two color so this was good timing. As others have said, lowest power at highest speed was plenty deep. I did not play with focus but I want to in the future for sure. I removed the plastic coating and replaced with vinyl transfer paper.

I have to agree with those that have said it, this stuff smells pretty bad. This was Rowmark brand.

Lovely markers!

That concerns me too!

Very cool!

I envy your mother her elderberry and sweet joe pye

One small correction (not to be rude!) I think it’s spelled “tansy”.

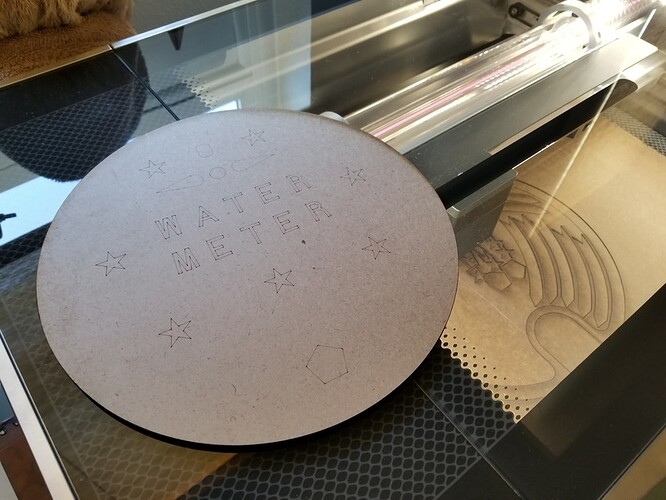

I work in the Civil Engineering field (I am actually a graphic artist, not an engineer) and there is not a lot of opportunity to offer up my digital fabrication tools in my day to day. Every now and then my employer asks me for some 3D printed parts for prototyping or to have something physical to show clients but not nearly as often as I would like. I have not been mentioning the Glowforge I had ordered because with the delays I never knew when I could commit and I did not want to find myself in a bind. Just after I received ‘The Email’ I was asked if I could fabricate a specific historic water meter cover to be given to clients that would appreciate it. I thought 3D printing was not the ideal approach for this and asked if they could wait until I had the Glowforge and a bit of time to learn my way around it. They were fine with that.

Today I printed the first prototype as a starting point for discussion on design and finishing. This initial version was made from 1/4" MDF and hardboard. Even though this is far from the final version, I wanted to share.

Wow, the final painted version looks very convincing! That’s awesome