Never thought about Rockler. My father-in-law and husband have purchased a lot of woodworking tools from them. Think they do carry a fair amount of different wood species for CNCs, and I guess might be compatible for lasers too.

That’s where I get my baltic birch plywood.

Also a lot of exotic hardwoods.

So what do you typically use the Baltic Birch plywood for? If you have a choice of maple plywood and Baltic Birch do you have a favorite?

Not really. The maple (Purebond) has a nicer finish and was cheaper. I used BB before Purebond was available.

So I placed an order the other day from Craft Closet, ordered the MDF that @dan84 suggested. They had wood veneer sheets, so I ordered some white oak veneer. Do people use the wood veneer over the MDF or would I use that over something like the Baltic birch or maple plywood…or does it matter? Wondering if I do use it over the MDF it the edges look bad.

People buy veneer because they want a thin layer of wood somewhere, like a bookmark, fridge magnet, wood patch, business card, or to layer on another material. White oak veneer over MDF would be called white oak plywood and is probably cheaper to buy that way than making it yourself. There are some designs in the catalog that might be a good use for the veneer you bought:

I found some scraps of 1/4" MDF from Home Depot that I had picked up for use on my X-Carve (CNC router) - I had laser cut parts from them but it’s been many years, I can’t guarantee it would be the same material now. You could give it a try but be prepared to test your settings. It’s also not masked. Of course, 1/4" is “thick”, not medium, but it cut ok.

That’s part of the fun of owning a laser, for me. Trying out different settings to come up with what works.

Edit - can’t find any local source of 1/8" MDF. 1/4" seems to be the minimum.

Gosh, I’m learning so much here in this one post! I would have thought buying a sheet of wood veneer would be cheaper than purchasing a sheet of wood veneer plywood! Thanks for passing on the designs from the catalog! I had no idea what I’d do with the wood veneer sheets. Just saw them and though, eh, I might want to put them on something to make it look richer! LOL!

See, that’s what I’m thinking we only saw in our local HD and Lowes were the 1/4" MDF sheets. I had bought some 1/4" hardboard from one of the local stores quite a while back and was able to cut through it, but it was really dirty. We have some kind of sheets that were used for shelving in the house we recently moved into that I told my husband NOT to pitch because I might be able to cut that stuff!!! ![]() I had forgotten we had it, so I’m going to give it a shot. It appears to be some kind of hardboard (very cardboard-like, but 1/4" thick or even a little thicker type pressed board)

I had forgotten we had it, so I’m going to give it a shot. It appears to be some kind of hardboard (very cardboard-like, but 1/4" thick or even a little thicker type pressed board)

I’ve been referring to the Materials Sheet on the Google Doc link you provided and have been in and out of it a few times this last week and the link worked just fine, but today when I’m clicking on it, there’s a message saying that the Google Doc sheet has been deleted.

That doc was outdated and had many settings that were incorrect or did not apply to every sample of the material they referred to.

Just use the default settings in the UI for similar materials as a starting point, and work out what works for the material you are using.

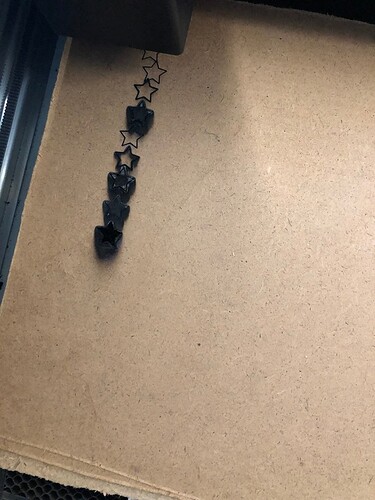

So I’ve been testing this stuff we have, and I’m not getting anywhere with it. Finally was actually able to cut through it though at 110/Full Power with 5 passes!! But then had to rush my little star to running water and dropped a hot coal on the carpet along the way that melted a tiny area of it…shhhh!!! It’s BRAND NEW, literally installed less than a month ago! ![]() But I just took a pair of small scissors and cut the area out! Felt like I was toasting marshmallows with my GF!!!

But I just took a pair of small scissors and cut the area out! Felt like I was toasting marshmallows with my GF!!!![]() Do you think I’ll be able to cut through this stuff? Any starting settings to suggest? Don’t think there’s hardboard settings in the UI, are there? Since we have so much of this lying around here, I thought they’d be a great use for the second layer for these so I wouldn’t then need to mess with three layers of chipboard and have to add sticks onto them . Thought I could just use the chipboard for the first intricate layer and then this stuff for the second layer that will have the stick already attached like the very first picture in this post.

Do you think I’ll be able to cut through this stuff? Any starting settings to suggest? Don’t think there’s hardboard settings in the UI, are there? Since we have so much of this lying around here, I thought they’d be a great use for the second layer for these so I wouldn’t then need to mess with three layers of chipboard and have to add sticks onto them . Thought I could just use the chipboard for the first intricate layer and then this stuff for the second layer that will have the stick already attached like the very first picture in this post.

I always choose the PG settings for my first test (even if my material came from somewhere else) and adjust from there. If you buy the material and have them cut down to 11X20, you will have lots of small scrap pieces on which to test.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.