I’m disappointed that the only material options in the drop down are the ones that are sold by GF. I have a thin flat stainless steel bracelet that I’m trying to engrave and each time that I adjust my settings it’s just not engraving. If anyone has used stainless steel and or jewelry blanks can you give me some insight on what I’m doing wrong?

You can’t engrave on metal. The laser is nowhere near powerful enough.

You can mark it by using third-party products such as Cermark, or remove existing coatings like anodization on aluminum.

Some people have had very limited success marking some metals without applying any coating, but it’s not consistent and probably related to some kind of finishing process that was applied.

Wow GF lists the ability to engrave metal on the FAQ’s?

I read in this form from other users that they used soap and a wet paper towel. I know it is my user error simply because I have the bracelet wrapped in a paper towel and it is not cutting into the paper towel either.

You can’t engrave steel but you can mark it permanently. Get some Cermark and follow the instructions.

Try doing a search in the forum using a few different search terms like ‘marking metal’, ‘Cermark’, ‘LaserBond’, etc…there are many, many posts that discuss various techniques. I myself have marked on stainless steel bracelet blanks using LaserBond 100 with good success.

Thanks!

Thank you for your help I am going to research that item right away. My other question though I think pertains to the settings since I’m finding it difficult how to create settings for materials that are not sold through glow Forge. As I mentioned previously I wrapped the bracelet in a wet paper towel after having read someone having success with that here in the community forum. My laser is not even reaching the paper so I need to figure out what I’m doing wrong when entering a material that is not on the GF list of materials.

There’s also using vinegar soaked papertowel which can work.

Seems stronger vinegar works best for this…

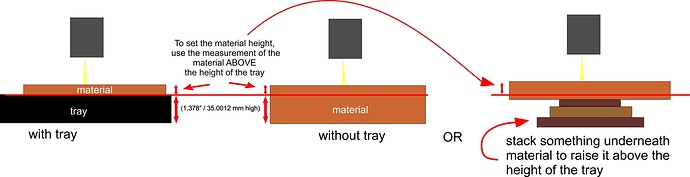

You might need to raise the item to be marked up into the correct range, especially if you are not using the tray. There is a diagram and discussion on working without the tray here:

Keep in mind, you can now use the Set Focus tool instead of doing the calculations, but you still need to prop the surface of the material up into the correct range, which measures from 1.4" to 1.9" from the metal plate in the bottom of the machine. If you are working on top of the tray it’s not an issue, but the item needs to be less than ½ inch thick to put it on the tray.

Also, if you haven’t run the Calibration Program yet, you’ll want to do that first to set the calibration for your individual machine.

Great tip about the calibration. I had not done that. I am using the tray.

What are you trying to mark? Is it something thin like silverware? That has another issue related to setting focus that is kind of hard to get around. (The automatic targeting laser has to land on it, not off to the side, and it’s hard to hit it when it’s skinny.)

Thank you so much I appreciate you taking the time to send this to me. I’ve been doing Embroidery for years and if I went through different brands of machines I could easily jump on board. Laser cutting is brand new to me and I’m finding it a bit confusing.

Thanks,

Nicole

No problem. (It won’t take you long. Very similar to how the Embroidery works, just a few different rules to learn.)

I just went back and read the specs - the only metals that GF advertises that it will work with are anodized aluminum and titanium. Anodized aluminum doesn’t engrave, the color dye in the color anodized aluminum gets removed to reveal the silver metal color under it. Titanium will do surface marking without treatment because it is such a poor heat transmission material. Some stainless alloys have been able to do some surface marking also, but they usually require some oxidizer to make the mark, like water or acid. Everything else will require a marking compound.

ben1 is correct. The only thing you’re really doing with a laser of this power on metal is marking it. This requires Cermark or another chemical as mentioned above to create an oxidation or glaze effect. Cermark is the latter. It takes significantly more power to actually engrave (etch) or cut metals.

I’m a Glowforge owner and I’m Director of Operations for a prototype company. We have a 400w CO2 laser for cutting metals. About 10x the power of a Glowforge. Even with that much power, we can barely cut through stainless steel 2mm thick.

As a point to that, on my milling machine to cut stainless I have to shift the drive to the low-range belt to get enough torque to cut through stainless. It’s tough stuff! And that’s a lot of power!

Not to pile on, but my plasma cuts mild steel about 30% faster than stainless at the same power levels. That’s with a 35,000 - 45,000 degree plasma arc ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.