Tutorial: How to cut objects too thick to have the honeycomb in place

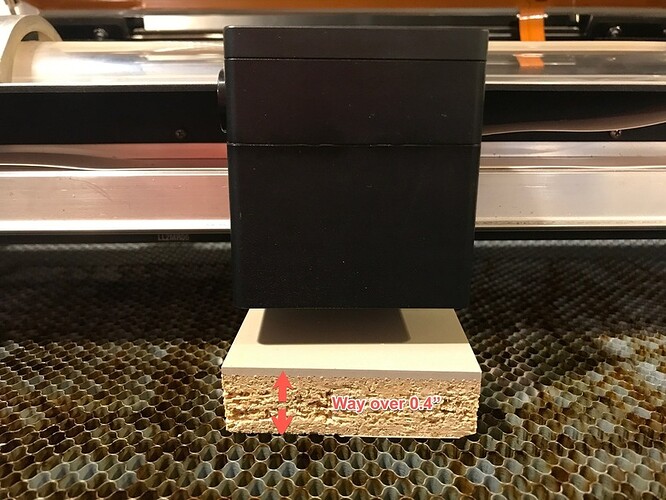

The GlowForge has a maximum material thickness it can cut through, but there is a maximum thickness you can even put on the honeycomb (crumb tray) even if you are surface engraving as the laser has a limited focus range of 0.01" - 0.4" *** above the surface of the honeycomb at the time of this tutorial. But let’s say you wanted to engrave something thicker that fits quite nicely inside the GlowForge but not with the crumb tray in place.

The process of figuring out how to cut with the honeycomb removed is pretty simple once you’ve gone through it. There are 5 steps (I will list them and then give detail):

- Measure how thick your material is

- Measure how deep your Crumb tray top is from the case (this is a 2-step process)

- Remove the tray from the GlowForge

- Find an object whose thickness is thick enough to put your object’s surface above the honeycomb and below the 0.4" limit

- Tell the software the material thickness is the height above the virtual honeycomb

Details:

Measure how thick your material is

This is pretty simple (for you non-Americans, sorry but you do need to use inches on your calipers currently - or do all the math in mm then convert at the end), just get the total average thickness. For a small item that is flat, likely one measurement is sufficient, but on a larger sheet, a few measurements of the area being cut onto is useful, and write down the average.

In this tutorial the Inventables Linoleum Stamp is 0.89" (in other words 0.49" thicker than allowed).

Measure the honeycomb surface height

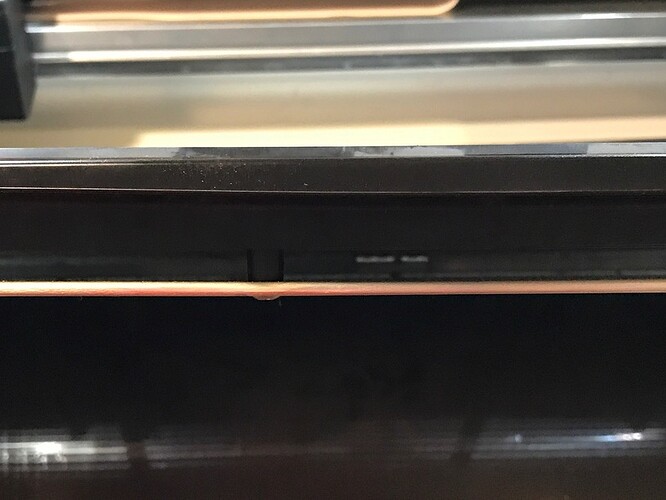

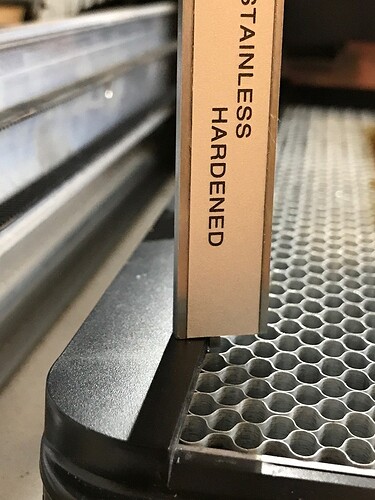

Now you might be tempted to just do this (don’t!):

(this is invalid as the honeycomb has an internal metal plate that is an actual crumb tray! You aren’t measuring the actual thickness!)

see the metal plate at the bottom sits above the case bottom.

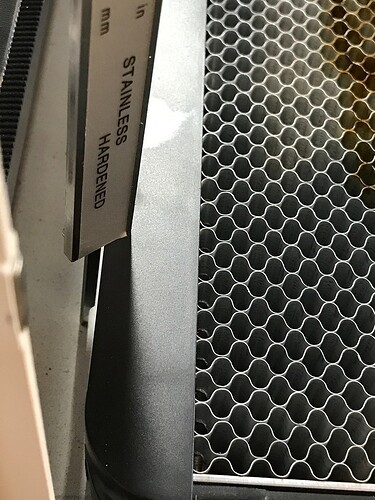

So instead we need to perform 2 measurements, since your part will be sitting on the case floor, you need to measure the height of the honeycomb surface above the case floor:

First measure floor to top of the tray using the depth gauge on your calipers (the spike that comes out the back)

(you can sort of sneak it into the corner)

On this PRU GlowForge the height to the top of the tray is 1.511".

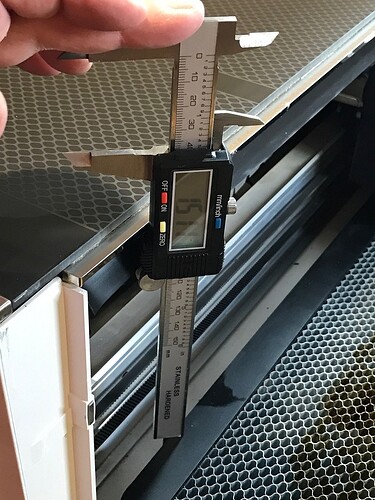

But wait, there’s more, because if you look you will note that the plastic edges form a nice square edge to place material against, but that is raised from the honeycomb.

So take your Depth Gauge and measure from the top of the plastic to the top of the honeycomb (yeah it’s thin, but you can make it work - remember you only will measure your tray once unless you change the tray out)

On this unit it yields a offset of 0.118"

So our total depth of the case to honeycomb surface is 1.511" - 0.118" = 1.393" total thickness (let’s make that 1.4" in this case for simplicity)

Removing the tray:

The manual undoubtably will have a set of directions, but it’s pretty simple:

Handy tip, make sure the gantry with the laser on it is all the way at the back.

Open the front door, slide the crumb tray out with tipping too much so you don’t bang into the laser. Note it is heavier than you remember. Close the front door.

Find an object

Remember while the object you pick isn’t going to get lasered (hopefully) you might accidentally overshoot or punch a hole through, so make sure it is laser compatible (blocks of scrap wood work great) and that it is something that you don’t care about (scrap wood again).

So how do we know the thickness? Well we need an object that will raise our material surface into the correct zone of 0.01" to 0.4" above the height of the honeycomb. Now in our case since we have removed the honeycomb physically, we have a “virtual” honeycomb in our mind of 1.4" above the case floor.

So we need the following formulas

(Tray From Case Height + 0.4") - (thickness of material) = max height of object:

(1.4" + 0.4) - 0.89" = 0.91" (max height)

Now for minimum height you need to think about how deep you’re engraving/scoring/etc, because you need to make sure that operation is within the focal range. So let’s imagine we want it to be 1/8" above the bed (0.125")

Tray From Case Height - Thickness of material + desired new height = minimum height

1.4" - 0.89" + 0.125 = 0.635"

So I need an object somewhere around 0.64"

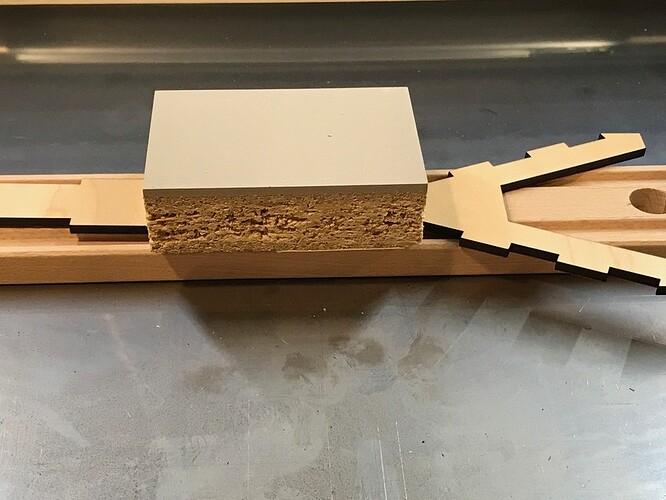

So luckily a brio train track and a piece of scrap proof grade maple ply were sitting around:

(yeah, not exactly what the example was calling for, but I just need to change the number I put into the GFUI to reflect that it is lower by 0.029")

So stack it all up like so

And in the GFUI you are going to enter the material thickness according to our derived thickness:

(Height of our object + material thickness) - Case to Honeycomb height = GFUI entered thickness

0.61" + 0.89") - 1.4" = 0.1"

(note if it comes out negative you are too thin [below the virtual honeycomb] and if it is above 0.4" you are still too thick)

***.

I’m going to add this here to @henryhbk 's excellent wiki tutorial, since it came up in another thread, and it explains just what we’re shooting for:

You have to place the top of the item to be engraved within a range that falls from 0.01" to 0.45" from where the top of the crumb tray normally resides.

A quick diagram to explain it:

The top of the crumb tray is 0.0" as far as the interface is concerned.