Greetings -

In case anyone is still interested in where this ended up, so far, here’s an update. I wanted to get all the old PLA melted into plates, and then cut into medallions, for future use. I’m also slowly working on a plan for a heated stamping mill of sorts. Anyway, here we go -

Melting station set up - with hose just in case. ![]()

You know the process from earlier in the thread, rinse and repeat - Ghost poop from The Cactus Pot project up first -

Bling - That’s pretty freaky…

Here’s some Ikea Skadis Fun pieces of scrap -

Ya, operator error on the first couple cuts, and had to move the piece to get through. Oh well, I could have just remelted the square, but the final coin stamps will remelt the surface anyway. they are colorful.

I also cut the Cactus Salsa noted above. As that material was PLA-CF (Carbon Fibre), I think the fibre inside absorbs the laser not allowing it to cut through nearly as fast. It took a lot of passes to get through, and scorched the edges. I probably won’t remelt / save that poop in the future.

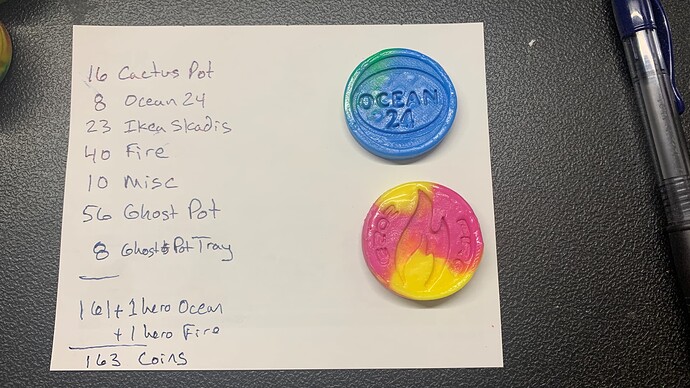

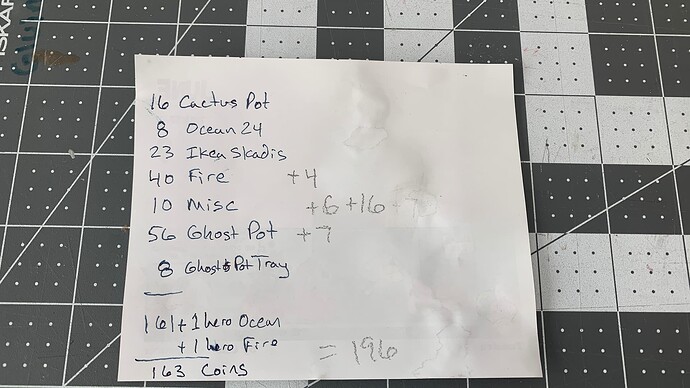

Anyway, what did I end up with - the number of coins per project, first melt. 163 total

I didn’t cut the ghost pot material as it was 9mm thick, and CF. I’m thinking I’ll cut it into smaller pieces and remelt super thin. IDK yet, so set that aside.

I then figured out, the left over ‘Square’ can be broken into pieces and remelted into the small circle mold, to yield 7 more 5-6mm (thick) coins. So (re)melt - Round two - cutting the square remnants into smaller circles.

After the PLA has melted twice, it’s starting to get brittle and the white in the ghost poop is getting brunt a little. So that going to be it for remelting. Final Total - 196 Coins.

Cool. Some were sticky and had PLA residue and such. So I washed them really well in soapy water and set out in the sun to dry. And here we are -

Some fun and usable base for another project, and another day.

HL