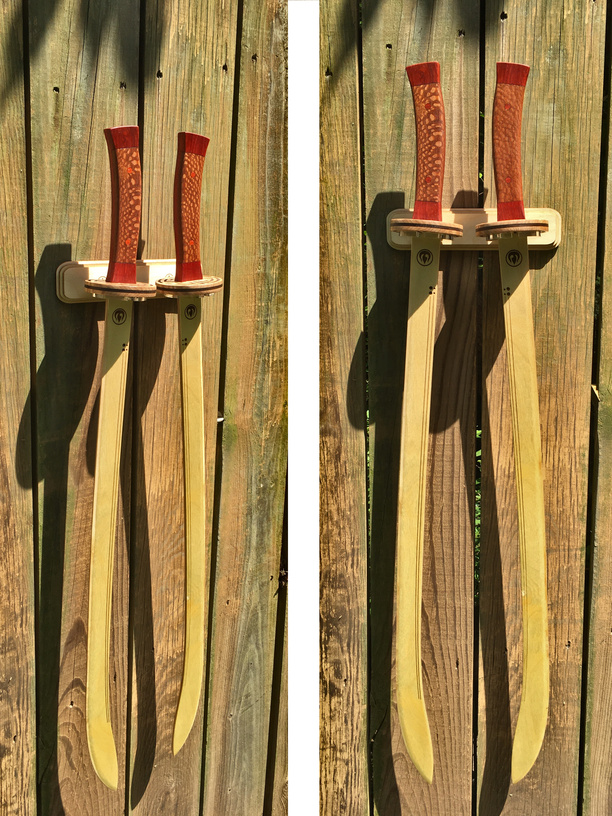

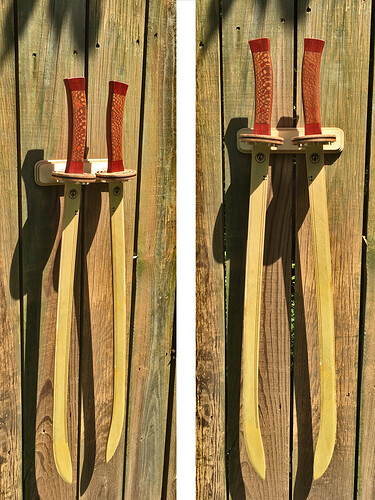

Hey, maybe you’ve seen us hanging around?

My niece has been into a TV show lately, one of the main characters carried a pair of dao swords. Seemed like a good gift idea, so I went for it.

The mount was a fun experiment. More on that later, but I wanted them to hang parallel, more or less.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

The handles are clearly the star of the show. I have had this leopardwood from Kim Oberlin hanging around for a while and could never find a project for it. It’s really striking when you polish it up.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

The bigleaf might look familiar, it was the same piece that I used to make the blade to my bowie knife. The dao is a chinese sword, so I went with a good luck themed engraving on the grossguard.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

The crossguard is engraved front and back, the design is slightly modified to make room for the blade or the handle, depending on which side. The walnut is sandwiched in the middle for some flair.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

The edge grain of the maple makes for a pleasing “herringbone” look.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

Another look at the handles, the leopard pattern is either very pronounced or quite subtle, depends on the angle of the light.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

Speaking of lighting, here’s a more true look at the color when you’ve got better conditions.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

The handle has a spine of padauk, enhances the strength of the assembly.

(Baltic birch plywood, padauk, leopardwood, walnut, figured bigleaf maple)

I did say we’d come back to the mount. The blades slide into the slot and then twist and lock into place. I’m pretty pleased with that design, it keeps the blades secure in one easy mount point.

(Baltic birch plywood, 0.2" cast acrylic)

Overall, I’m happy with how it came out. I don’t think I’d do it the same way next time, but that’s neither here nor there.

BTW, bonus fact, this was based on a 18th century dao in the “oxtail” style. It can be found on wikipedia:

I based the sword’s geometry on this almost exactly, and made an educated guess on the overall dimensions. Oh also, this is still a secret, so nobody tell my niece, k?

Check out my Pai Sho work if you’re interested!

Check out my Pai Sho work if you’re interested!