EDITED - SOLUTION FOUND

TLDR: Trying to engrave a project found that random letters were dropping out of the copies of the coin across a grid of 112 iterations of a single image. Looked like possible GF failure as source file was fine.

Solution: Source was Corel Draw that was Saved As an SVG. In the save, Corel’s translator dropped random letters.

Result: For non-native Inkscape users, your source file for the GF is not your AI or Affinity or Corel file, it’s the SVG that gets saved. When troubleshooting open the SVG in Inkscape to identify if it’s file based before looking at GFUI as possible issue.

Other problems noted with preview rendering and size of usable cutting space remain unresolved.

END OF TLDR SECTION; BEGIN ORIGINAL DISCOURSE (removed superfluous processing that seemed to point to continued issues with the GF rendering of the coins so future readers don’t get hung up on the details)

Trying to make some giveaway souvenir coins for our upcoming Mini MakerFaire and had an odd failure. The coins are 1.25 inches diameter and have some vector text on each side. I setup a sheet of 14x8 coins on a 20x12 artboard. The coins take up 19.125" by 11.05" centered on the board.

The front consist of engraving the text and cutting the coins from the full sheet of PG Medium Draftboard. The coins are flipped and the obverse side is engraved only.

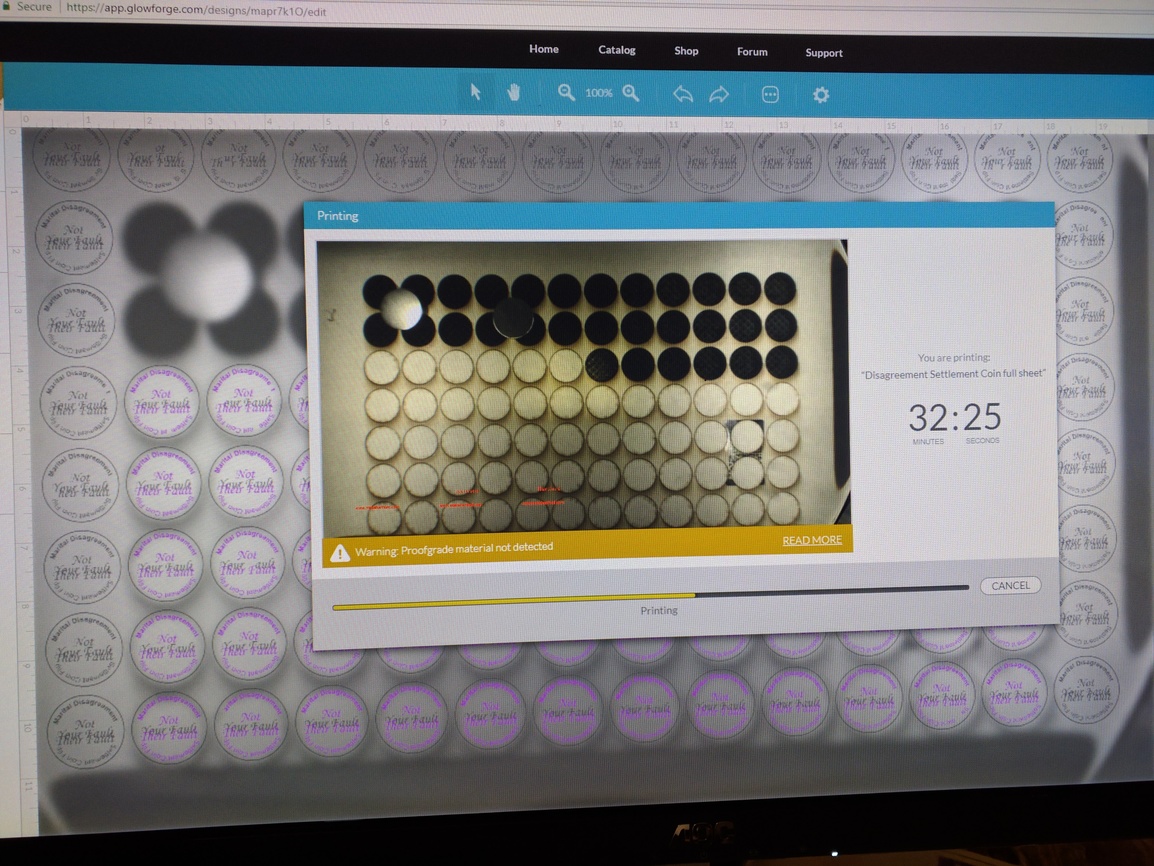

The entire project was loaded into the GFUI and all rows and columns were present. I set the engraves to “dark” and the cut was the default. I set the obverse side engraves to ignore. Pressed Print and it gave me a 2:12 (hrs, minutes) countdown. I pressed the glowing button.

After the job was done I noticed a couple of issues. Two columns - the far left & far right did not engrave or cut. They were simply disregarded. They do not show on the GFUI as being outside the permitted work zone. They just didn’t process.

The top row also failed to process despite not being shown as outside the permissible print area.

So instead of getting 112 coins (14x8) it only cut 84 (12x7).

Then random coins starting about halfway up the stack also started to randomly lose letters - not partials or skipping engrave lines but whole letters. All of the coins were simple copies of a single one and they were all grouped before saving the SVG. In the picture below you’ll see the coins that worked I’ve flipped over to do the obverse and the ones that didn’t I left to show it’s not like the laser misfired on a horizontal pass on the engraves.

The close up shows the randomness of the letter drops. I had started flipping them over before I noticed the problem so they’re not entirely lined up correctly but since it’s not a problem skipping whole raster passes but one where it skipped letters that it did not skip in surrounding coins the picture shows that.

Of the 84 that cut, 40 were misengraved and useless - nearly a 50% failure rate.

They’re also randomly placed in the rows although most are in the upper rows. The empty spots are where the bad ones were.

So I pulled the bad ones and put the good ones in the lower 5 rows hoping I’ll be able to get good obverse engravings. I reset the obverse from “dark” to reduce the LPI from 340 (default) to 270 hoping if it’s a size issue for the job I’ll be able to salvage the half that were okay on the front. I set the cut to Ignore and resubmitted it for print. I also deleted the two and a half rows that were now vacant since the fronts were bad - no sense in wasting processing on blank bits of the honeycomb. This time it came back with a 1:12 runtime.

The red progress view does not show the real progress but the coins are processing all correctly for this batch.

Temperature in the room is 72F, RH 38% and the time was approximately 1pm Eastern. No temp alerts or cooldowns observed.

The problems were:

o Failing to process 2 columns & 1 row despite showing within the cuttable zone

o Random dropouts of individual letters (not raster lines) in random coins across the top half of the bed

o Inaccurate rendering of the progress in the pop-up window