I wondered what the upper limit was to the “resolution” of wood when it comes to engraving, so I tried to test it.

Lessons learned:

- LPI matters. All of these pictures are the same speed and power, but higher LPI definitely yields better detail and darker contrast.

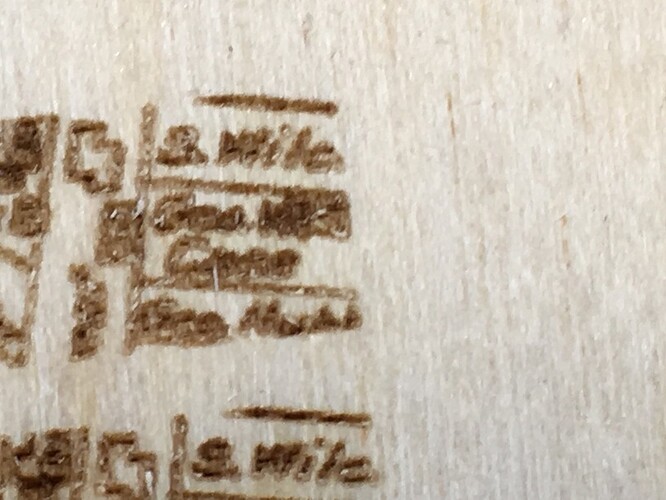

225 LPI: Note the muddy details, “Case” is almost illegible.

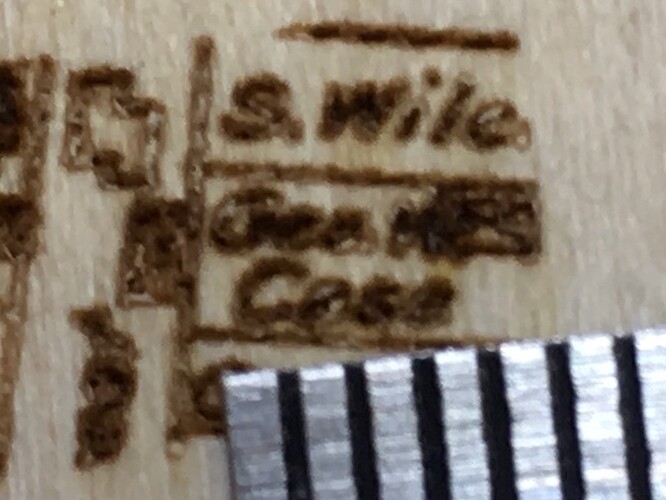

370 LPI: Clearer and crisper with darker engraving.

-

Cleaning matters. Cleaning the smoke residue from the surface will make your details much more legible. At this scale paper towel lint destroys the engrave, so be gentle. I recommend denatured alcohol.

-

There is an upper limit to the practical resolution of wood fibers, and while it probably varies by species, for birch it’s somewhere in the area of roughly 220dpi (features 0.0045" in size or larger) in terms of features that can be resolved, and a good bit larger to reliably resolve them. This is where it gets tricky, because expressing it as a digital DPI doesn’t make a lot of sense – because wood is an analog system – so I saw serious differences between LPI settings, getting a much better result up to 340 LPI.

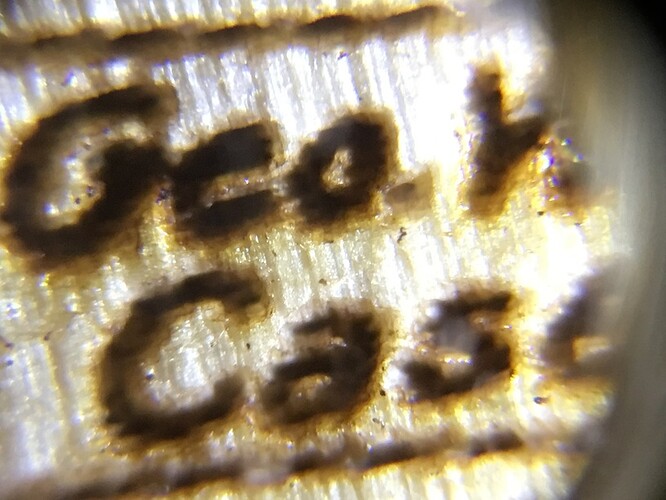

At the very smallest scale I was able to get results:

225 LPI:

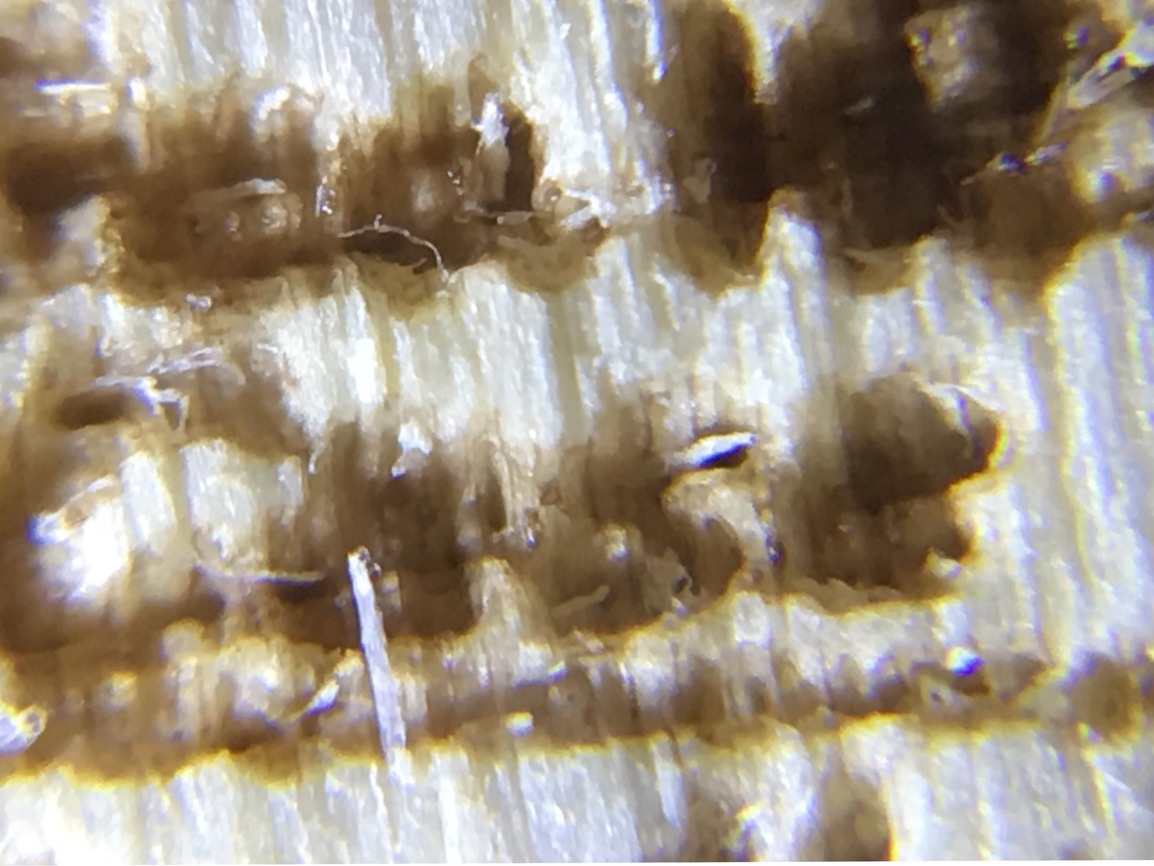

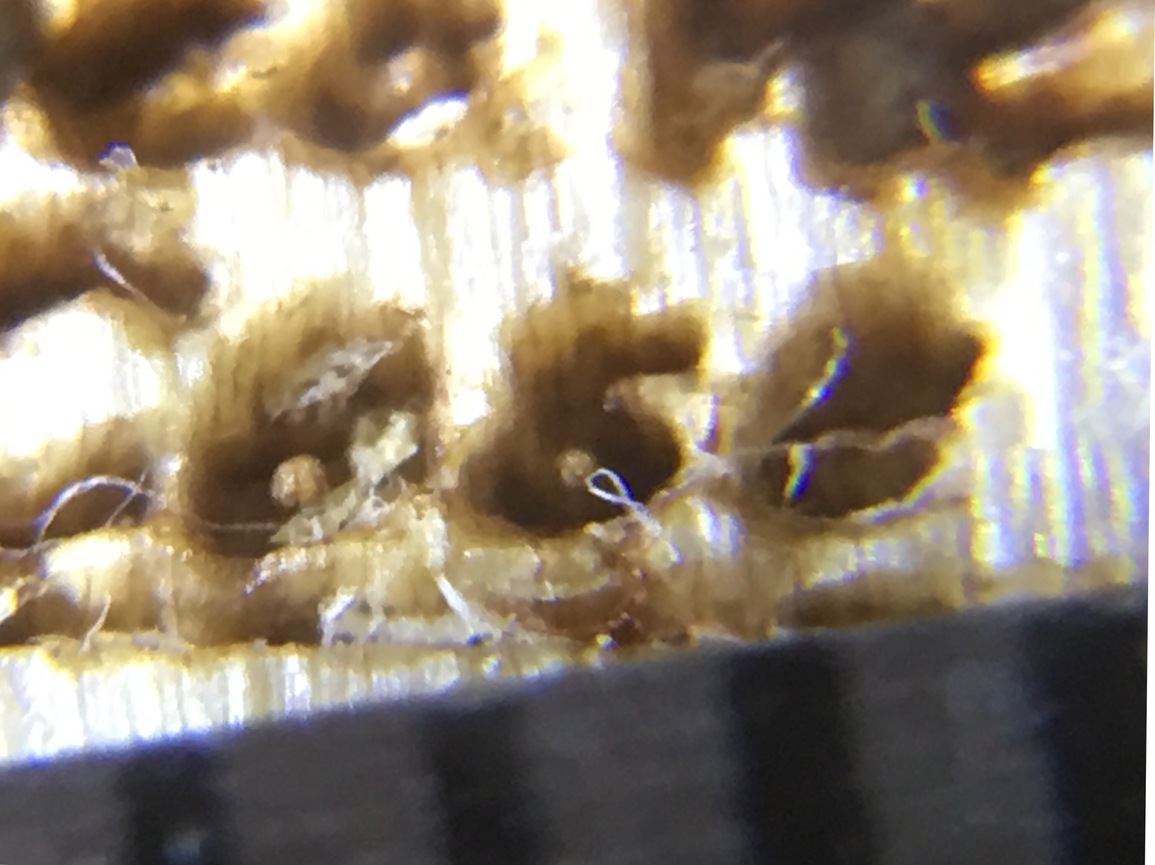

340 LPI: The fibers are from paper towels. Again, do not use them ![]()

At a much more reasonable scale (about 1.5x the previous examples) , the text differences are immediately obvious:

225 LPI:

340LPI:

Testing method:

I started with a very finely detailed source file and imported it into Inkscape, and scaled it to various sizes to see how small it could be resolved.

I used the settings 900/80 and increased LPI from 225->340.

The 340 LPI engrave is far clearer, and much more detail is resolved.

Once I had pictures I went back to Inkscape to measure the shortest dimensions of the smallest features that could be resolved. The lower part of the “e” in “Case” was it, at about 0.0045" tall. This is highly subjective, and will depend on lots of tiny details, probably down to exactly where in the wood grain you’re engraving

I’m not sure what practical stuff to take from this, except to say that the LPI and cleaning makes a huge difference, and keeping your smallest desired features to at least 0.01" across (probably 0.02) is good practice for yielding the best engraves.

Time to revisit my older engraves and see if I get similarly improved results with higher LPI. I suspect I will.