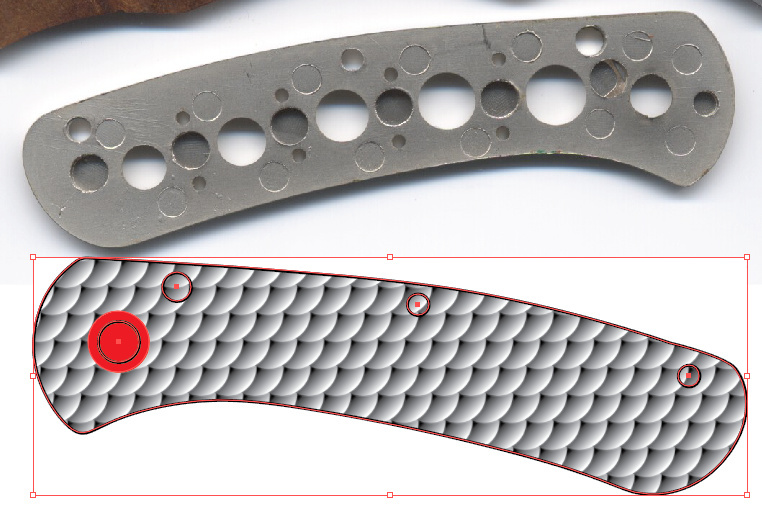

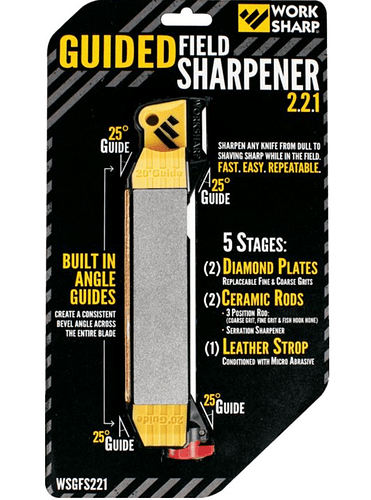

Since I was able to get some practice in with creating 3d textures via deep etching I decided to try making something more practical with them. I had an old knife that I wanted to dress up a bit. First I took the existing side plates off of it so I could scan them into the PC with my scanner.

On my first try I had the countersink etch set a bit too high in power so it actually etched all the way through making a giant hole. The second try I was able to get it to work much better. The holes all lined up the way I had hoped and I was able to install it on my knife pretty easily.

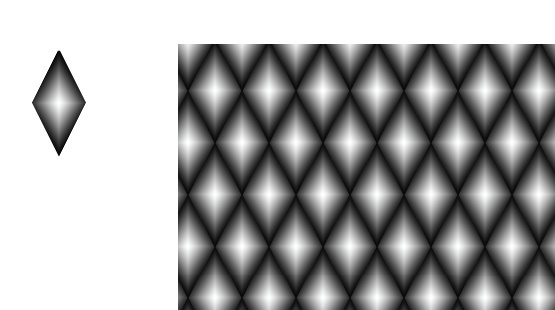

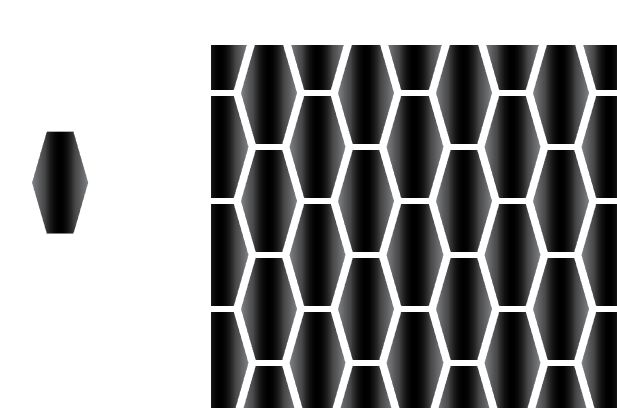

I was pretty happy at this point. The texture was comfortable, grippy and looked nice as well. However, I wanted to try making some more textures to test so I made two more. A traditional checkering and a hexagonal one.

I was pretty happy at this point. The texture was comfortable, grippy and looked nice as well. However, I wanted to try making some more textures to test so I made two more. A traditional checkering and a hexagonal one.

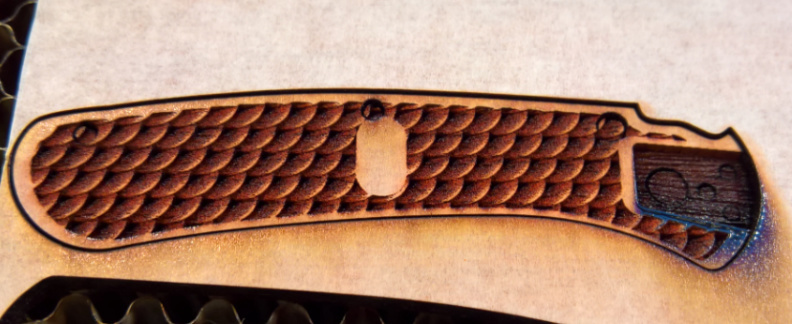

They etched pretty well too.

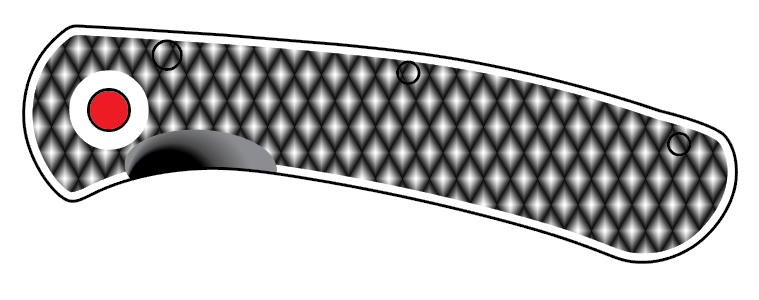

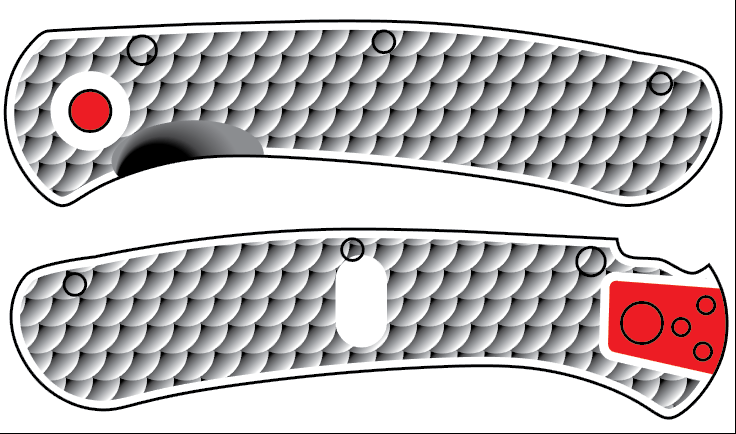

I decided to try and add some thumb relief to the design as well so it’d be easier to open the knife and a border to smooth out the edges of the handle and ended up with this.

so I tried the different designs on different woods to see how they’d look.

as you can see, sometimes the etched thumb relief was just too deep and burned through. I decided I liked the fish scale in Padauk (?) best and updated it to have a ridge around the edge. I also had to design the back side of the knife which was a little different, but fairly easy to model giving me this:

The texture etches about halfway down into the wood, so around 1/16" deep grooves. This was one of my earlier tests, but shows how deep I was going with it (single pass with room to go deeper if I wanted).

Even right off the laser it’s pretty much fit to go other than needing a bit of cleaning.

Washing it with a toothbrush and some scrubby soap and it looks pretty good.

Some quick work with a screwdriver and it mounts nicely.

The main screw countersinks nicely and the smaller ones fit flush without countersink etching.

I may need to enlarge the main pivot hole on the back plate because the nut doesn’t sit flush on the back which props the clip up a bit when I screw it down.

But, overall I’m pretty happy with how it turned out. I think I’ll try the other two textures in the other woods later and see how they look as well. I may also just sand/file the thumb relief, but not sure yet.