The simple trick of cutting out a rectangle and flipping it, to align a double-sided engrave, is an essential technique.

What if the rectangle doesn’t fit when you flip it over?

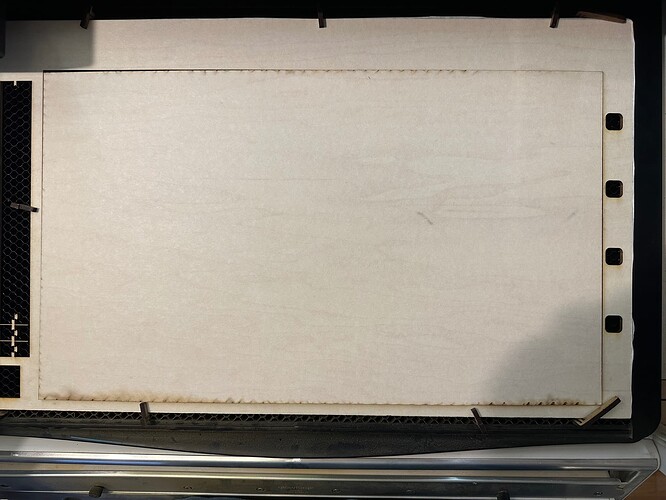

I ran into this problem. This rectangle wouldn’t fit, no matter what I tried. It was a parallelogram, not a rectangle! You can see a 2mm gap on the top left. (On the bottom left, it overlaps the frame by 2mm.)

The cause was that the Glowforge’s horizontal arm was slightly askew, not at perfect right angles to the side rails. I had just spent 5 hours engraving the first side, and a 2mm error wasn’t within my tolerance. A disaster!

What to do?

For my project, the slight distortion of shape was acceptable, but I needed precise alignment of cuts on the second side to the engraving on the first side.

First, I didn’t touch anything. I didn’t turn off the Glowforge, and I didn’t realign the horizontal arm (yet).

Next, I placed the rectangle as you see it above: The right-hand edge was set flush with the frame, and the left-hand edge was out of place. I used calipers to measure the error (2mm).

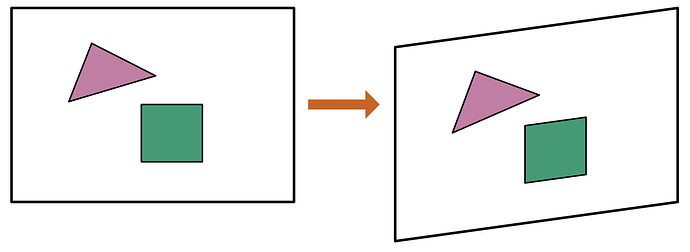

Then, I reopened the vector file in my editor (Affinity Designer), and applied a compensating skew to the design. I dragged the left-hand side down by 2mm, like this (exaggerated):

Consult your editor’s manual for how to do this.

I saved the change, opened it in the Glowforge interface, and aligned the right-hand edge to its original location. It worked out fine; the cuts on the second side were aligned with the engraving on the first side. (The slight distortion of shapes was within acceptable limits.)