I’ve thought of that, as well. Maybe some engraved acrylic to make it look as pretty as possible. My vent is going out of some very old, sliding windows…which are my favorite windows in the whole house…so the nicer looking, the better.

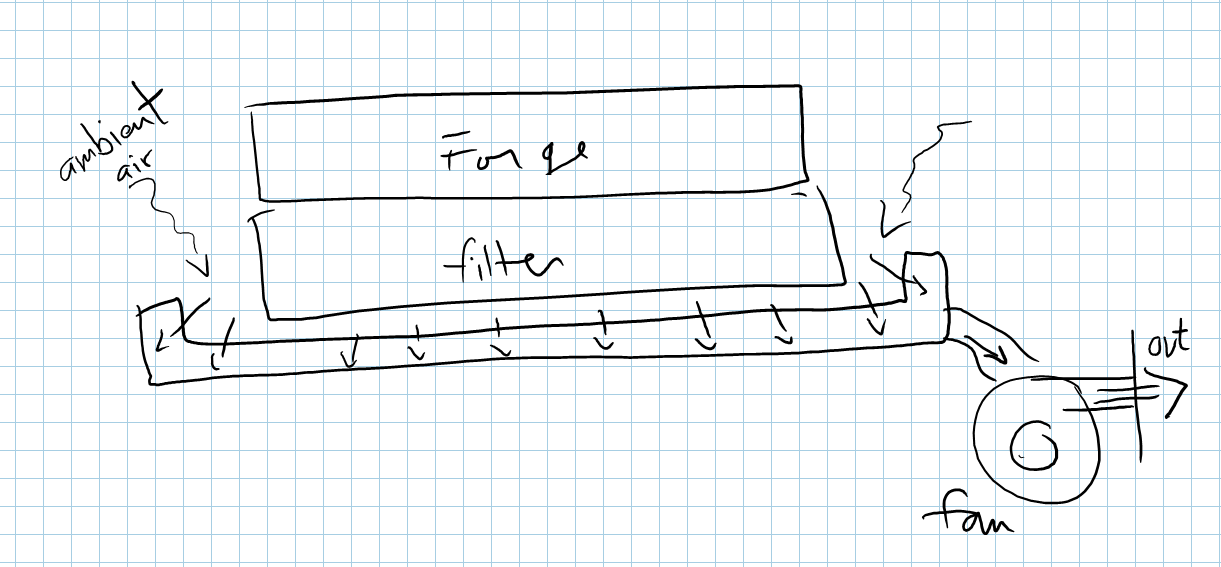

You could construct a base for the Forge/filter combo that would actively draw the exhaust air into an exhaust fan and out a window. Might not catch it all, but it would get most of it, I bet.

If you did that, you’d want to make sure that the exhaust fan was interlocked to the GF so that it wouldn’t run without it. Otherwise back pressure could be interesting.

I’m just thinking of a base that captures the air around the filter, not connected directly to it. So if it ran while the Forge was off, it would just draw air in from the room. No back pressure.

Oops, sorry, I was unclear. I meant so the the GF wouldn’t run without the exhaust on. Because then the GF filter would be exhausting into a mostly-enclosed space.

I wonder if I can vent the Pro w filter rather than use the filter if I have a 4" vent available?

@dan has said that the filter unit is separate. (as in ships separate) and that it can be used with or without. I assume using it without would require the separation of the two and setting it up for venting. Not sure how much that would entail.

From what I understand, there is going to be some sort of connection going form the exhaust of the Glowforge to the intake of the filter. To bypass the filter we should be able to swap that connection with a dryer hose without having to fully separate the forge from the filter.

I didn’t mean to imply you would actually have to separate the units but thanks for clarifying. I believe you are correct.

here is some exchange about this:

[quote=“dan, post:41, topic:626”]

Correct.[/quote]

Vent on the back of the GF.

No filter on-site at Maker Faire to check it out… I think. I’ll run back through and make sure.

What are you guys brainstorming for a design - without using passthrough?

I’ve got one on the backburner which I’ll have to fine-tune when I get my 'forge… but it just relies on a standard automotive filter and raw carbon.

http://community.glowforge.com/t/sketching-out-a-diy-filter/1492

The advice here is spot on - you can use either the filter or external exhaust. Ideally you could have both and choose whichever worked best.

We will notify you in the UI if the filter needs to be changed. In the hopper is emailing you as well.

I was just curious since a standard single hang window is a 2020 (24"x24"), meaning construction something 24"/23.5" wide.

Most of the window-based screens/filters/birdfeeders/etc I’ve used have the main part and then adjustable side panels.

Looks like another great exposure for Glowforge. To all of the glowfolk who gave up their weekend, well done!

Regret not being able to attend.

I’m curious how does the machine sense the filter needs replacement?

You could do a 4 panel approach with some fancy joinery techniques to show off with.

Or if you just want quick and done, simple joinery. Make some molding style covers to place over the joins and keep the window more airtight even.

Will it give some warning ahead of time, or failing that, still allow use for some time after said warning, to allow us to continue using it while we await the new filters?