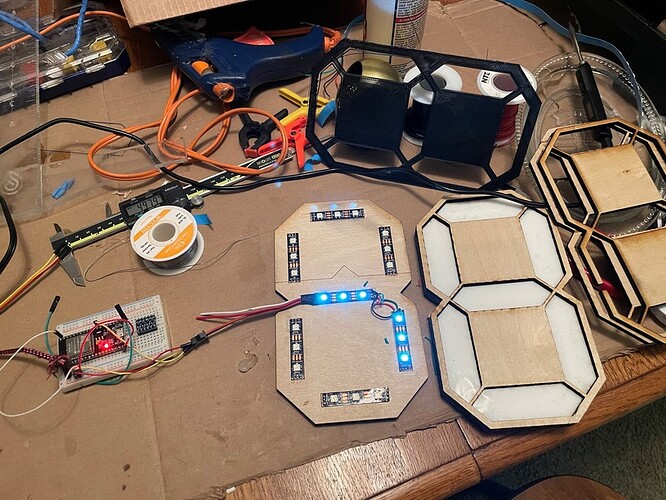

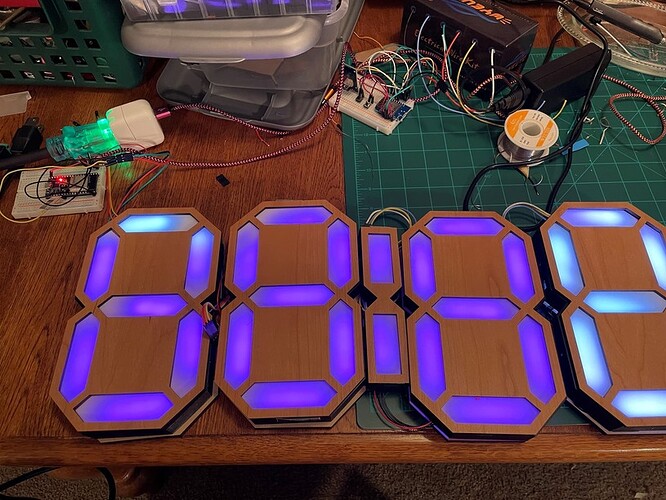

I have been inspired by Ivan Miranda and many others. I figured I would do the word clocks like @ben1 does, (whoops. I mean @mark14) which use LED matrixes, but ended up getting strip LEDs first to figure it out. I started out with four digits and was so happy with them that I made two more.

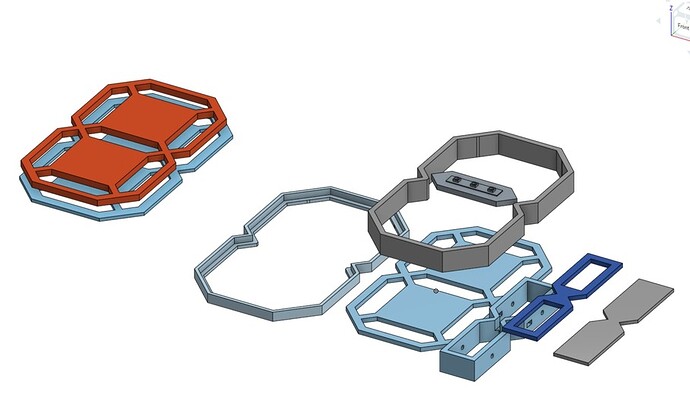

It was a great experience. Learned a few trick in Onshape. Got my maker card punched a couple times like first perf board circuit, first time using a circuit design software, KiCad. First time using ws2812b LEDs. First time using ESP 8266s (before had used ESP32s). The most libraries loaded to the Arduino environment. First time frying a microcontroller. First time de-soldering a board. First time using an RTC and switches to control a program other than blinking a light. Got to learn about WLED to control the individually addressable LEDs. Wow. It’s an amazing program and easy to use. First time using a logic level shifter (although ended up not needing it for this run). Already thinking of version 2.0 which would get dimensioned to use Proofgrade better and not use 3D printed parts, so all laser cut.

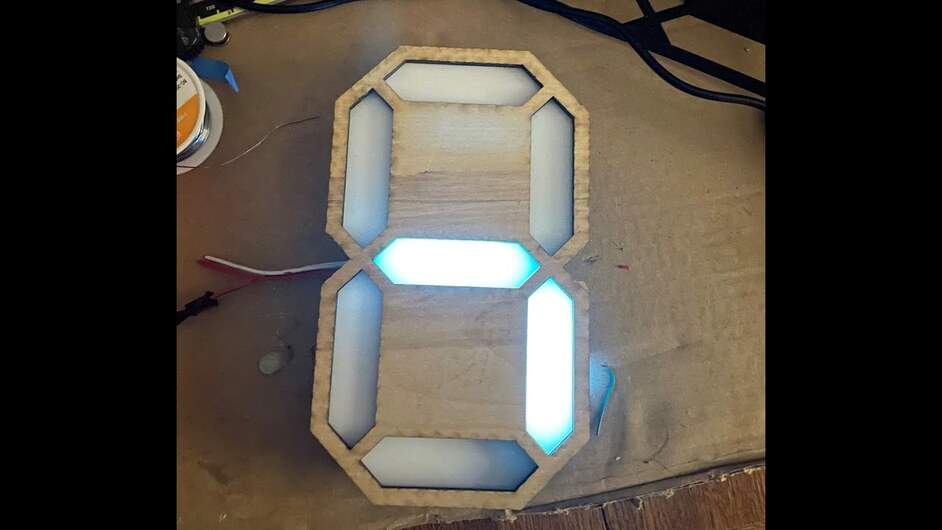

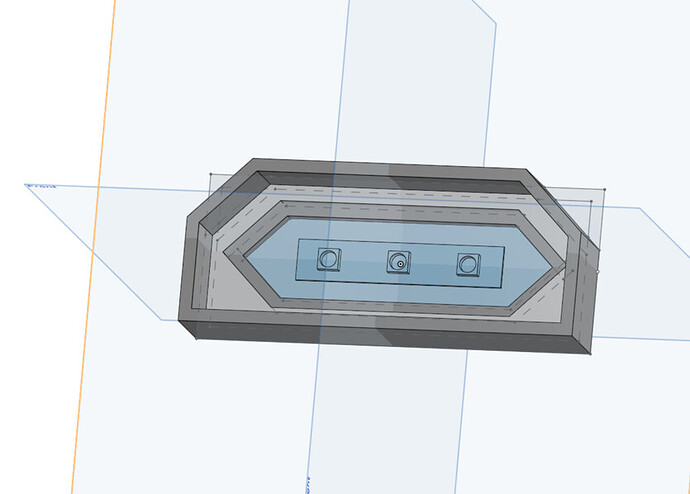

I love Onshape and Kiri:Moto. It makes these project so much easier. Started with a test piece to see how the white acrylic I have would work and how bright the LEDs would be. Also to see how I big the sections would be. You can make a 7 segment with all the same lenses, but there are models that have a couple different shapes which make the digits a bit easier to distinguish.

One of the goals was to make it as easy to make as possible. I could have 3D printed the letter housings, but that would take a lot longer. I have found a happy medium in printing sides with the 3D printer and bases and tops with the laser. I used cardboard to prototype.

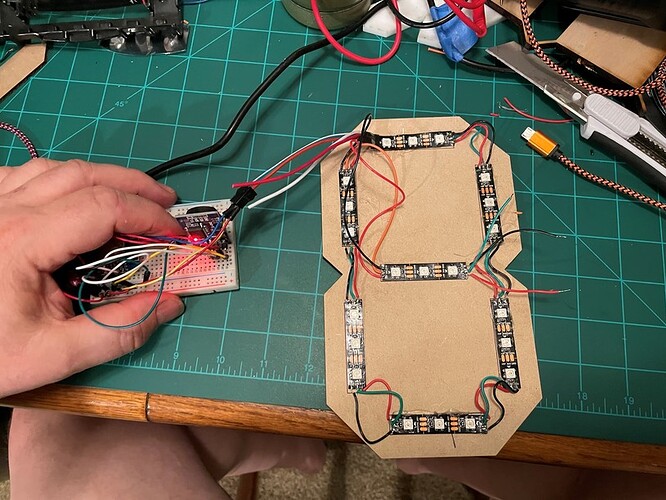

Several layers were needed. The top layer to trap the lenses. A second layer to align the lenses. and then a third layer to isolate the lenses so that there is minimum bleed from segment to segment. Then a bottom layer for the LEDs and the back. Next version will add one more layer in the middle for the LEDs and then move the wiring to the back of that layer. The conundrum is encountered. If the LEDs are on the back layer, how does one attach them to the side of each digit and then join them with a three prong dupont connector?

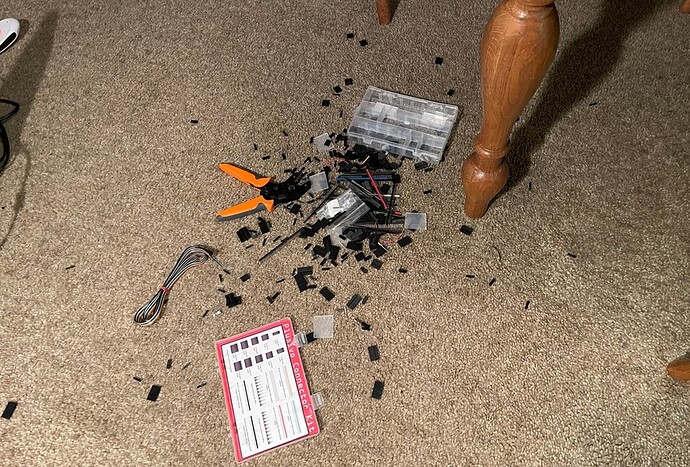

One of the decisions I had to make was how to join each digit. I had a box of dupont connectors and a crimper and had the wire on hand. I’m still learning.

I don’t have a proper workbench at the moment. I use the dining room table. Things fall on the floor all the time. I would like to talk to a watch maker and learn some techniques on how to handle dropped items: tools and parts. It’s maddening.

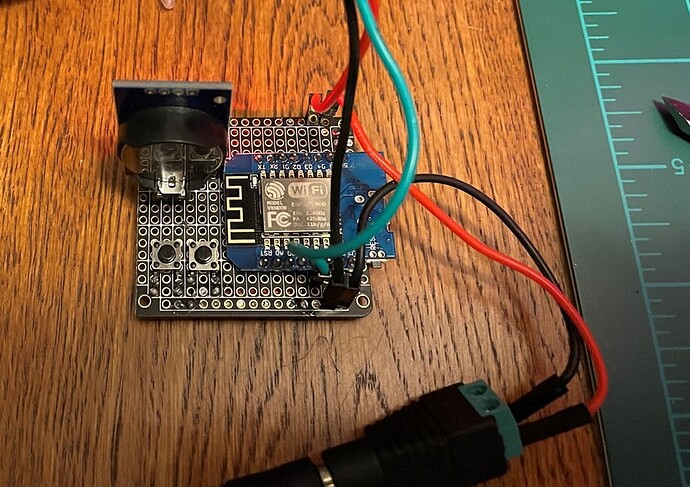

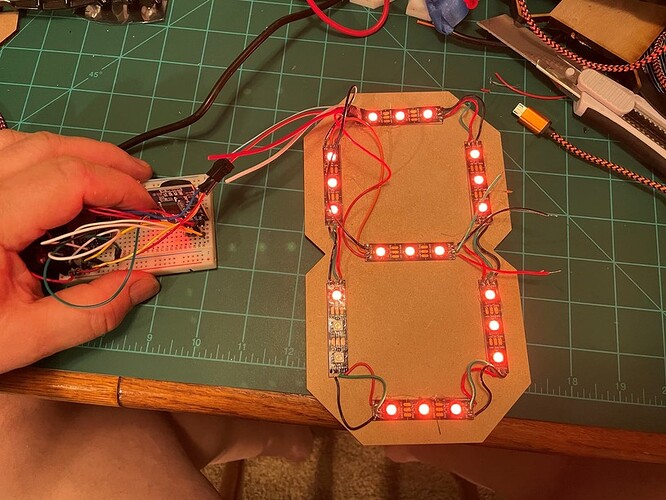

The WLED control environment is absolutely amazing. It was good to test the digits as I made them before I had enough to run the clock and get the clock controller set up. Once I got to four working digits, I started on the clock controller. I am so indebted to all the folks who freely share their code.

The code worked right off the bat once I figured out the pinout for a D1 mini controller.

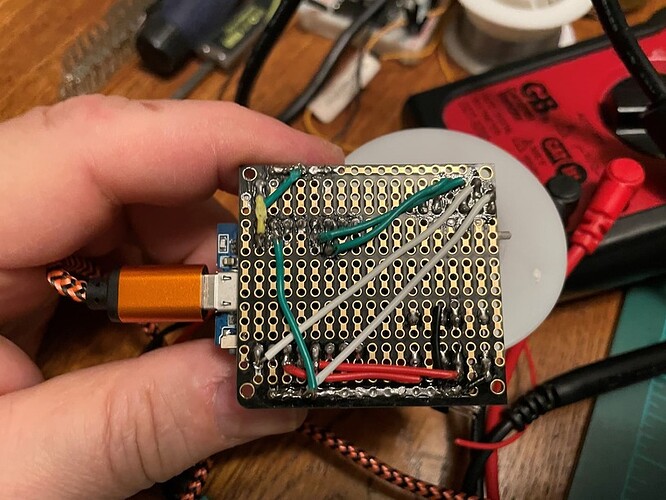

So I added two more digits. It was working great. That’s when I started transitioning from the breadboard to the perf board. First time. I spent a while getting the circuit down and did some one on KiCAD for designing the board. Lots to learn there, but at least I got my feet wet. It drives me nuts that all these guys shell JLPCB and the like for making boards for cheap. Sure, easy for you to say. You actually know how to design a board that works.

It may not be the prettiest, but it’s mine and it worked. Well, first time it didn’t. Forgot the main ground to the microcontroller. Easy enough to fix.

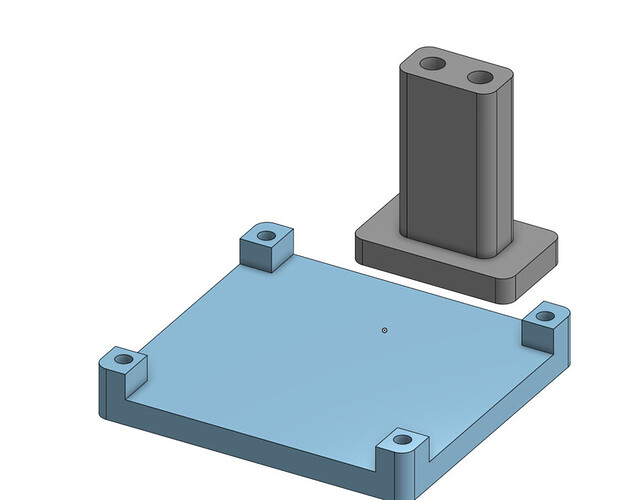

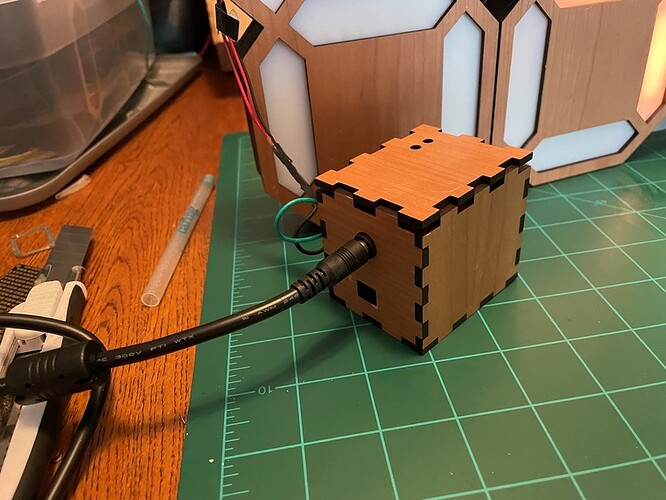

So I went on to making the control box. Used the Glowforge for the enclosure and 3D printer for a base.

The silo looking things are for guiding some type of pin/rod down to actuate the push bottons . It’s sized for a ballpoint pen ink canula. Used some threaded inserts for the base which work great. Hot glue to fix everything else.

So everything was working perfectly. Just needed to put some glue for the backs to set them first and hook up the project box. Whoops. Something was in backwards. No magic smoke but I did fry the D1 mini.

I had a conundrum. I had extra for all the parts except the real time controller. Do I try to desolder the D1 mini and use the the old board, or start from scratch? So I ordered solder wick and a solder sucker. Was not able to detach the D1 mini, but I did manage to free the RTC. In the meanwhile I got three more RTCs so I can make a word clock or two and another 7 segment,

So a few days of waiting. Did the final connection and put some hot glue where needed and shrink tube as necessary. I am very pleased with this project. I do think I’ll make the next version so that it is all laser cut though.

I used Proofgrade Cherry medium plywood for the faces. Used thick Draftboard for the lens brackets and back of the digits. Used some 6mm white opaque chemcast for the lenses.

Joined the digits together with small nuts and bolts through the sides.

By the way, I love my Glowforge. It works as I need it. I can’t imagine not having one.

Another personal note. I was the athletic director for a high school once upon a time. We needed a new scoreboard because our gym scoreboard didn’t have all the necessary feature. I had to hustle some sponsorships to come up with $8,000 for a board that used incandescent mini bulbs that we had to replace a few regularly before games. Of course it drives me nuts to think that with a bit of help, we could make a good scoreboard for much less these days.