They’re a good start for sure!

I think some of these jigs can be optimized a bit — they all use the maximum amount of material to make the jig, and the wooden pen jig in particular has excess dead space between the pens.

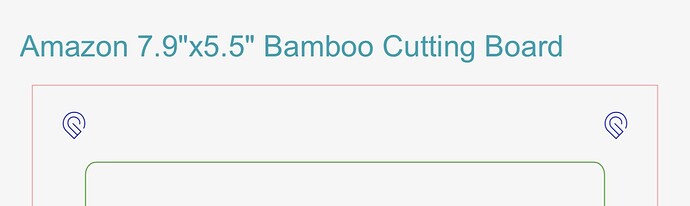

Taking the cutting board jig as an example:

Even if we make no other changes to the jig, you simply don’t need the bottom half. This becomes an edge jig at this point:

Pretty much every one of these examples could save a great deal of material on the jig by using edge jig techniques.

I’m also not a fan of full encapsulated jigs like this because if you’re off by even a little bit on your measurement you won’t be able to fit your item in it. Edge — and especially corner — jigs have the advantage there because you just slot the target item into it. In the cases of pencils or watch bands it might make sense to make an encapsulated jig that would prevent the air assist from really getting at your item and moving it around, but I think those things are the exceptions, most items are fairly heavy like a cutting board or a coaster.

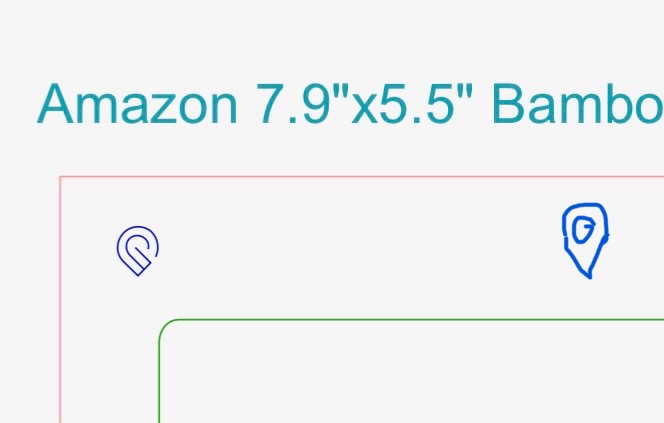

So our cutting board jig can become a corner jig, something more like this:

(Complete with my terrible hand drawn snapmark  )

)

This would save around 90% of the jig material in the process. (And really you could make it even thinner, probably saving another 30% of the small design.)

You could go even smaller but you do need separation on your snap marks so overall width has a lower bound. I forget what the guidance is but the distance between them helps with accuracy and I think there’s actually a minimum. Maybe pubultrastar or someone can help us out here with official guidelines?

Anyway thanks to @pubultrastar for giving us so much inspiration here, snapmarks are some users’ white whale killer feature, I hope snapmarks deliver on their promise.

Side note. I dictated this post and Siri had one really funny mistake: Bob Ultrastar :). It was so good I almost left it in. Hah I just didn’t edit and it came up as vulture star. I must be mumbling this morning lol)