TLDR; This is not a feature. This is a suggestion on using a physical target to assist the Glowforge UI in auto centering / aligning designs on small one off materials. This is a THEORETICAL idea on how to do it. NOT AN ACTUAL FUNCTION.

This is a continuation to this thread. But this thread is mostly for single, one off ops.

Has the same idea- But used to recover failed ops.

As it sits now you have to manually align things in the UI. If you are doing a large batch- @takitus link has the best approach. Read it.

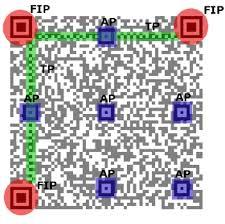

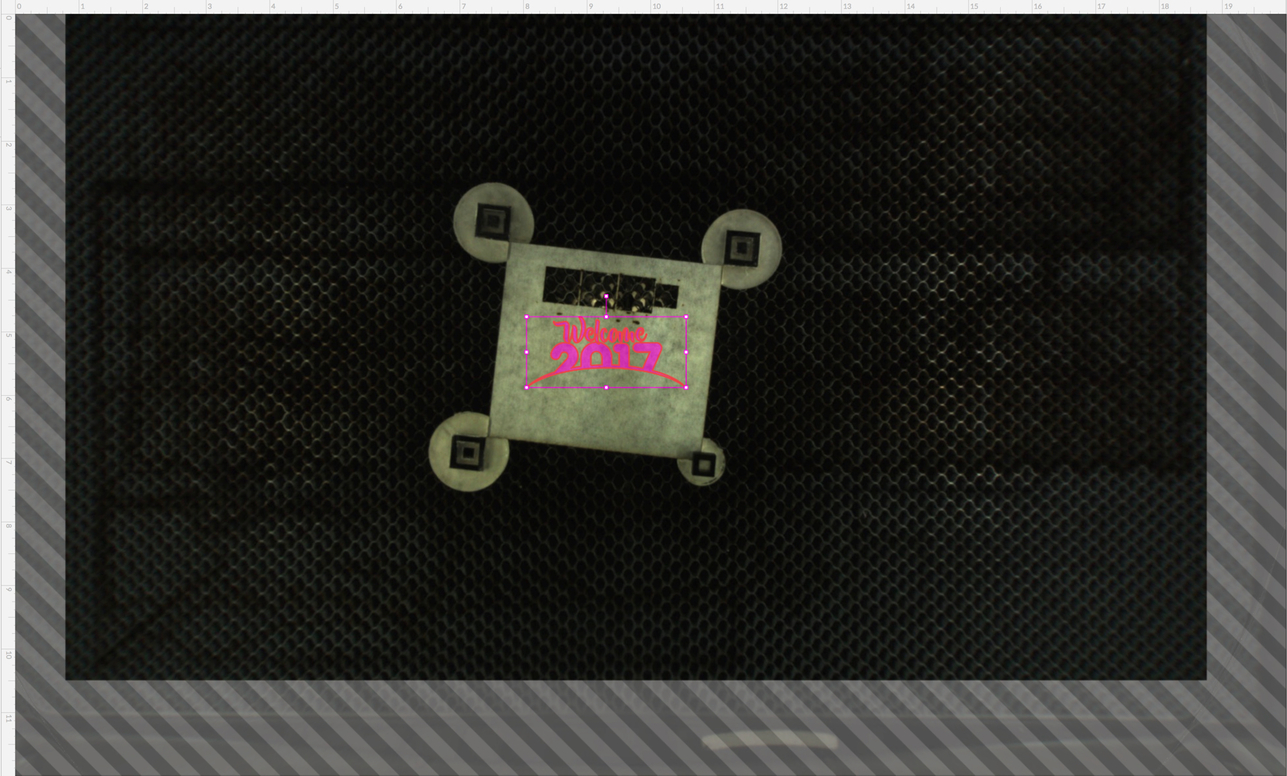

What this thread is about is single one off ops not really worthy of a jig. The idea is to have physical targets that the UI can see and align to without having to edge detect the actual material itself. QR codes have an alignment/orientation correction built-in. The glowforge already has QR detection capabilities. Classic ‘You put your peanut butter in my chocolate…’ Though this suggestion is a mod of that function. Specifically the orientation function. Once again. This is a theory.

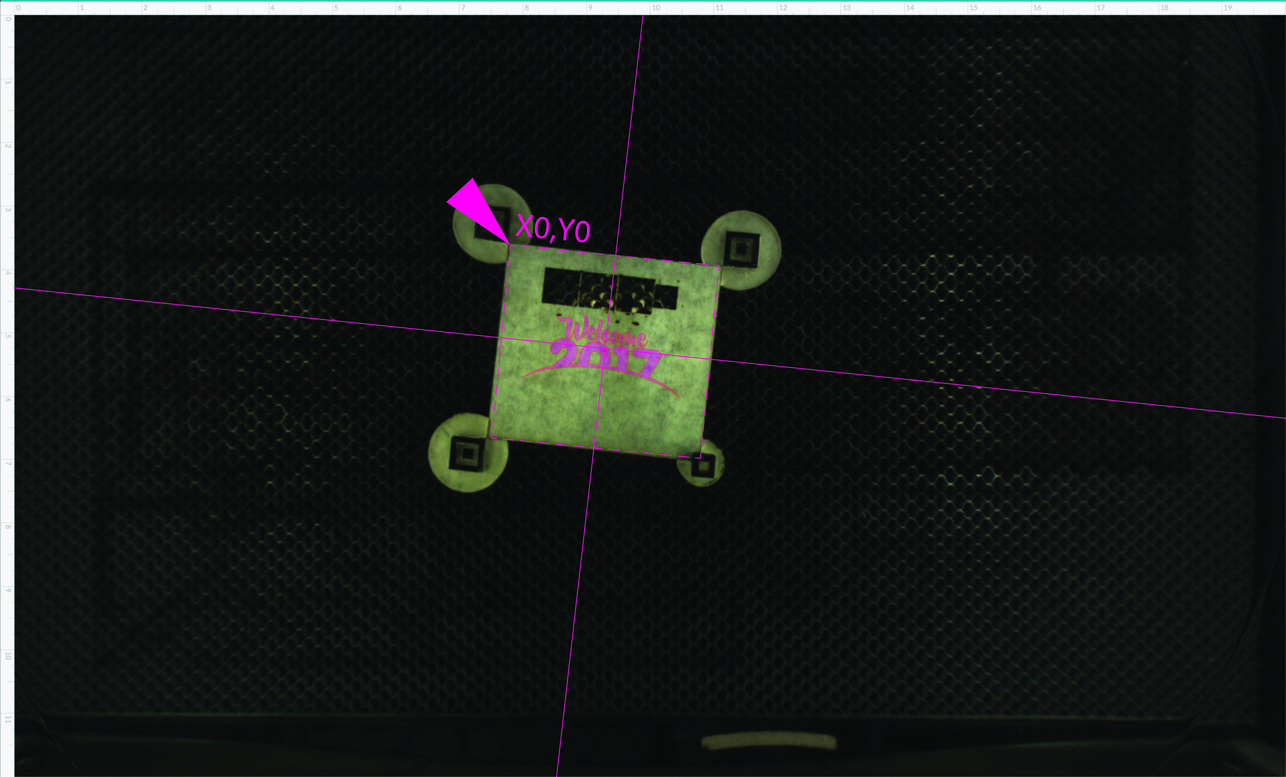

The blue ‘boxes’ in the image above marked ‘AP’ are called the alignment pixels.

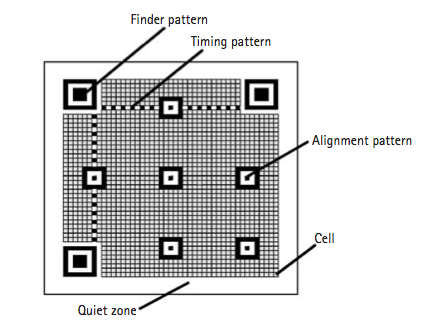

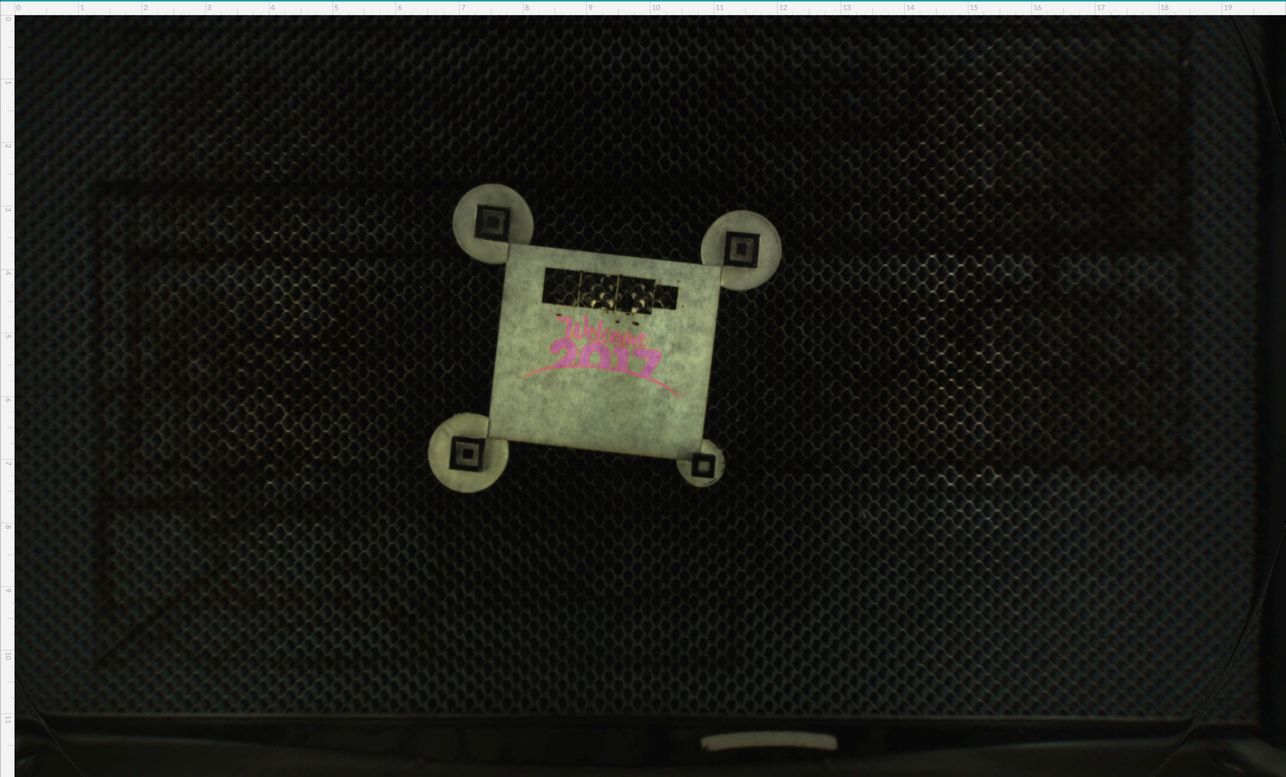

Another example.

.

.

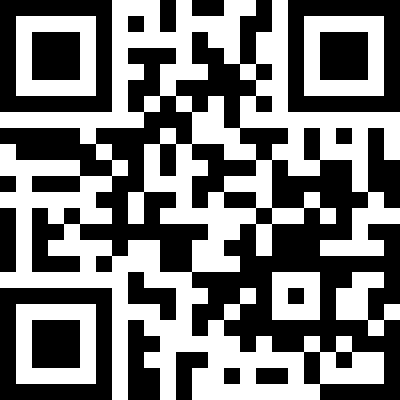

Example of an actual QR code.

So here is the idea. Use a QR code minus the ‘data’ portion of the code.

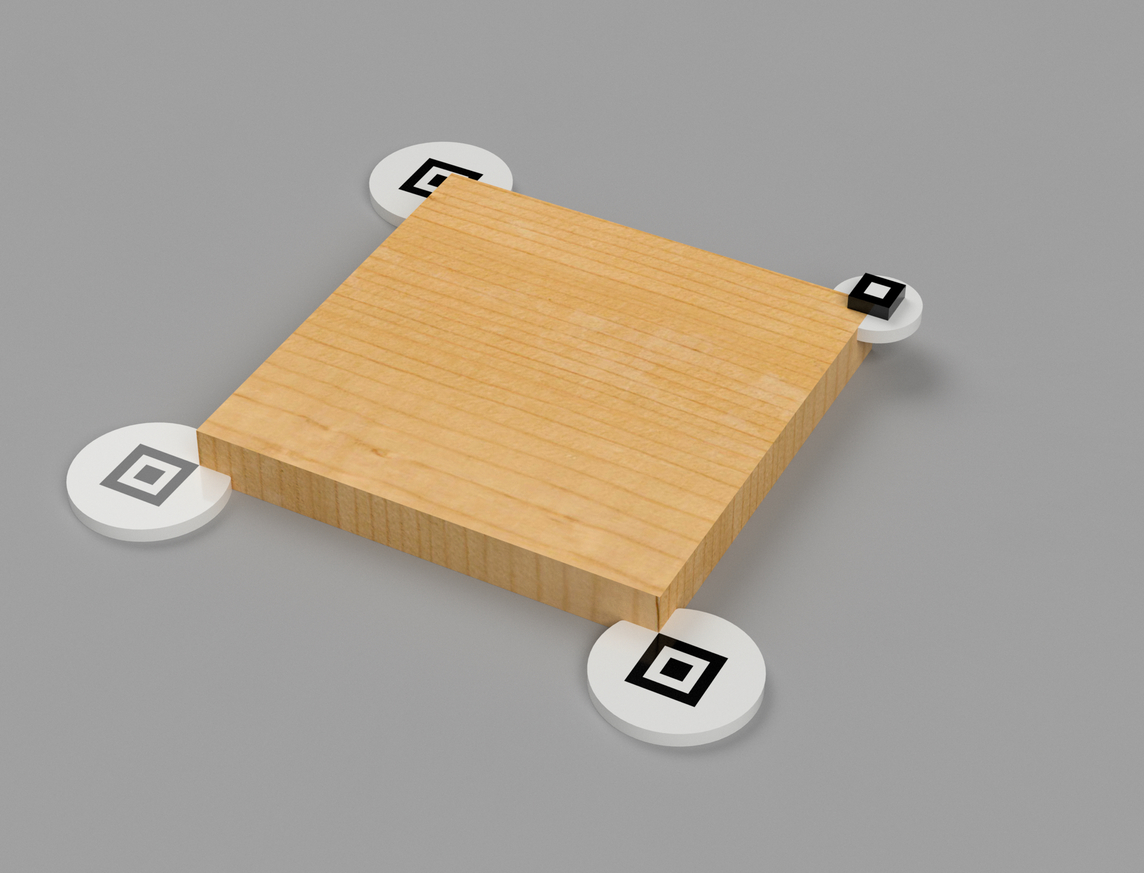

Use case. You drop in a small piece of a material. And import a design.

On the backend of the UI it sees the alignment patterns and works it’s magic.

Once the shape is discovered it would take the two sides (X & Y) and divide it in half and make a snappable location in center in the UI for the enduser. The side effect of this now that it knows shape and and the where the center is, it could assign a 0 orign. So you could just make the file about the size of the material it would figure out the orientation and snap to known zero. Theoretically.

What the end user would see. (or more?)

Hopefully this helps Team Glowforge.

Anywho, Here are the parts getting cut out.

Fun fact. Both proofgrade frost and black were cut out at the same time.

Here’s a picture of the setup I use to take the videos.