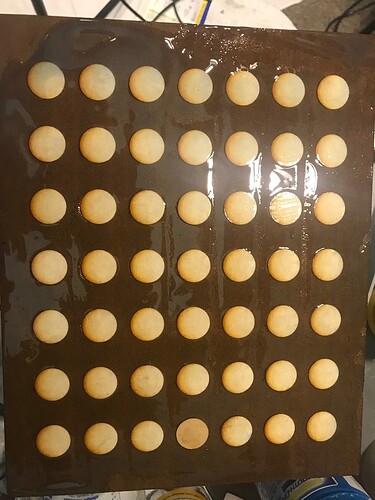

So if you saw my post about the Strangest print failure ever, the molding actually worked. I produced a fenestrated 0.5mm sheet of silicone (this is for a medical device). This stuff is insanely thin, and very hard to peel off the draft board despite gobs of mold release compound… (haha the silicone picks up some of the char)

Just think what you could do with fruit roll ups…lol

Seriously though…thats super cool!!

Oooh, sounds like a stop at CVS on my way home… What to cut into it?

Ha ha. Was just trying to add this comment

Wonder if now I’ll hear Challenge accepted on the fruit roll up…lol

So my grandmother’s friend’s son was part of the team that developed fruit roll ups. Several boxes wound up at our house during testing as my sister and I were in the target demographic age. I thought they were awful; she loved them. Pretty much sums up our tastes.

That silicone material is fascinating - where do you source it? (thinking minimally-reactive lab equipment that isn’t glassware)

It is Dragon Skin 10 from Smooth On which I get at the Reynolds Advanced Materials store near the lab (disclosure: they also partly sponsored my booth at MFNY).

I  Reynolds! I wish their hours were better for hobbyists, but life goes on.

Reynolds! I wish their hours were better for hobbyists, but life goes on.

How do you get such a nice, thin, even layer of the platinum-cure stuff?