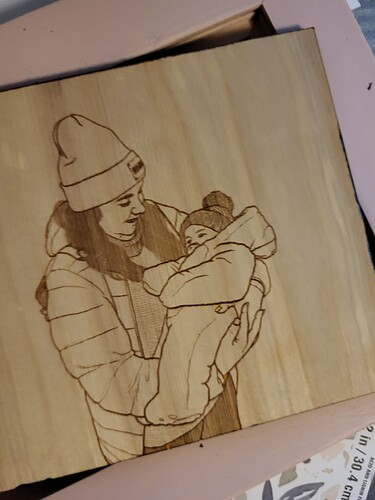

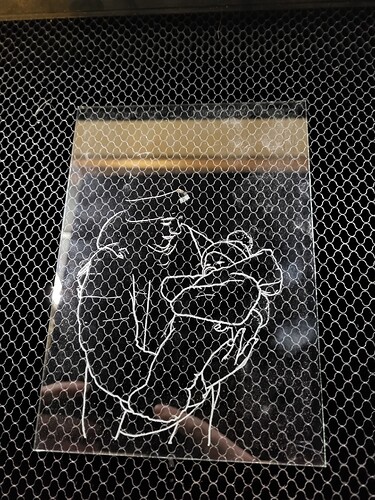

I am having trouble getting the results I am hoping for with my glass project. The image I am using is a line drawing with a separate layer for the fills. I got it to work great with wood, but decided to go for glass instead. I tried to alter the settings to fit the glass but its not going through as easily. What settings does every one use and what material or thickness??

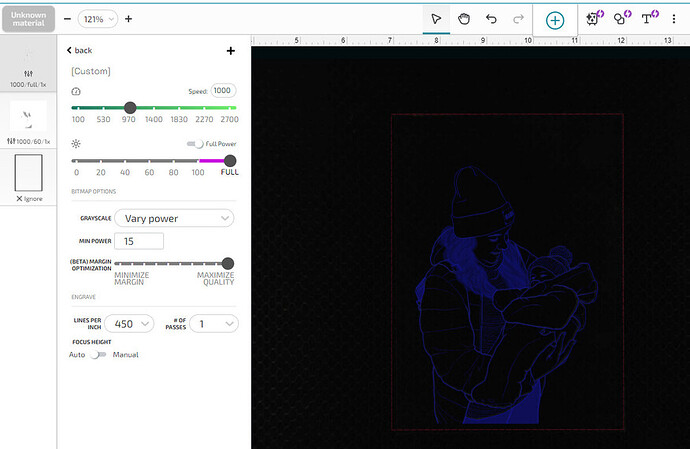

I don’t really do glass, so hopefully someone that does will chime in with tips. I just notice that part of the design is set to engrave at 60% power. Your image isn’t black and white line art, it’s shaded in various shades of blue, that are mostly around 50-60% brightness. So they’ll engrave at half of 60% power, which isn’t a lot of power compared to the parts that are coming out clearly. Maybe a more crisp line art style, or at least turning it black and white and darkening those lines, would help?

Yes that is the layer I wanted at a lower power to show up lighter. That is the fill layer, which didnt print at all ![]() so maybe I will need to turn that one up. But I dont understand why her hat and sweater lines are not coming through??

so maybe I will need to turn that one up. But I dont understand why her hat and sweater lines are not coming through??

Glass doesn’t really do “lighter” - you’re microscopically shattering the glass. Possibly change those fills to convert to patterns or dots, at that way the lighter will be further spread out.

FYI, ![]() doesn’t acknowledge layers, if you want to change the settings on things you only have to make them different colours

doesn’t acknowledge layers, if you want to change the settings on things you only have to make them different colours ![]()

I know some folks have had better luck coating the glass with a thin layer of liquid soap, so that might also help.

Try these:

I seem to remember a while back that glass required masking on the front or the back, because it distorted the laser beam and passed through vs doing what was expected

Glass just isn’t going to do clear sharp thin lines like wood. You’ll need to adjust that artwork to fatten the thin parts, and lower your expectations.

The good news is since this project looks like it’s a flat piece, you can use LazerMask and recreate very fine details with an abrasive etch process.

The bad news is, it’s expensive. You’d need an air compressor (>$75) and abrasive blaster tool ($75). And LazerMask itself is expensive. They’ll send you free samples but a roll wide enough for that piece of glass $200-250. So… Figure out some other glass projects to make use of it all. ![]()

This is the way…

Another thought is that you could try reversing parts that you engrave.

When I engrave the shot glasses I put dawn dish soap on there and let it dry.

Unless actual glass is critical green glass acryllic is indistinguishable for most folks and engraves very much better. If you go to dots and a high LPI and full power regular soda-lime glass should work. A little experimenting will still be needed for all the other settings. There is also an adjustment at each end of the light to dark so you get enough dots at the light end and enough space between dots at the dark end. The fact that glass will transmit any color you can see makes no difference to a CO2 laser as at those wavelengths all glass is black. That is why greenhouses work.