I know I am very late to the vacuum tray party but, I finally got around to making one. This project owes a lot to the previous examples here.

I did the design in Inkscape. I used one of the tabbed box generator extensions ( GitHub - paulh-rnd/TabbedBoxMaker: Inkscape tabbed box generator plugin - quickly design complex "finger jointed" boxes ) for the two main bodies: the tray and the fan box. I modified the output to break the pieces into sizes the Glowforge can cut and, to add additional features like holes for the fan and electronics and channels for air flow.

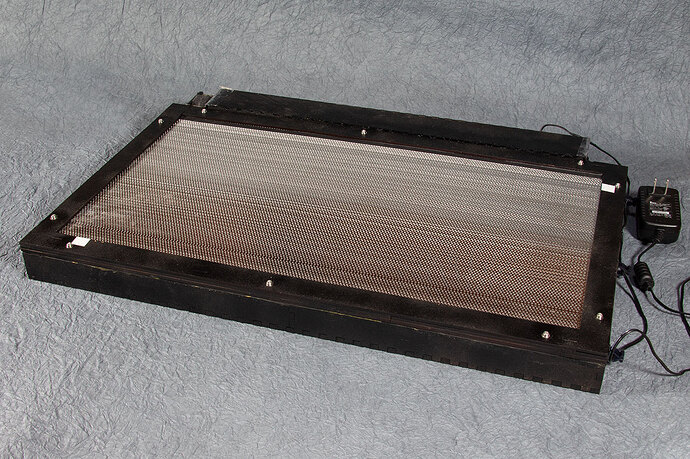

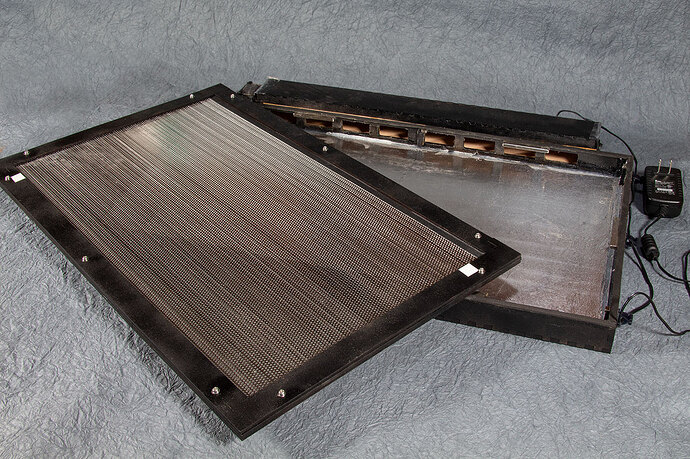

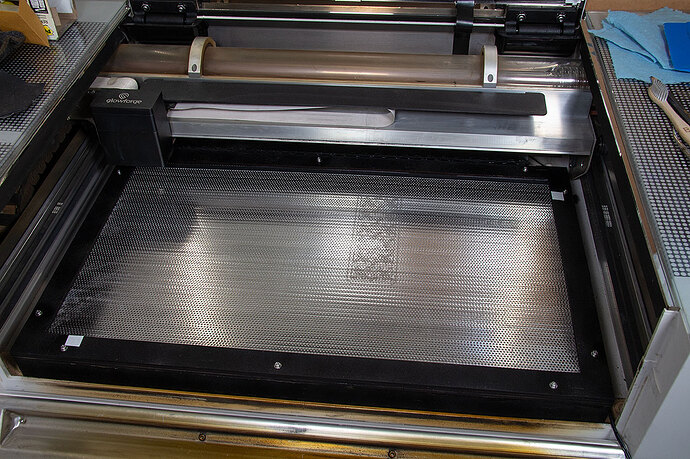

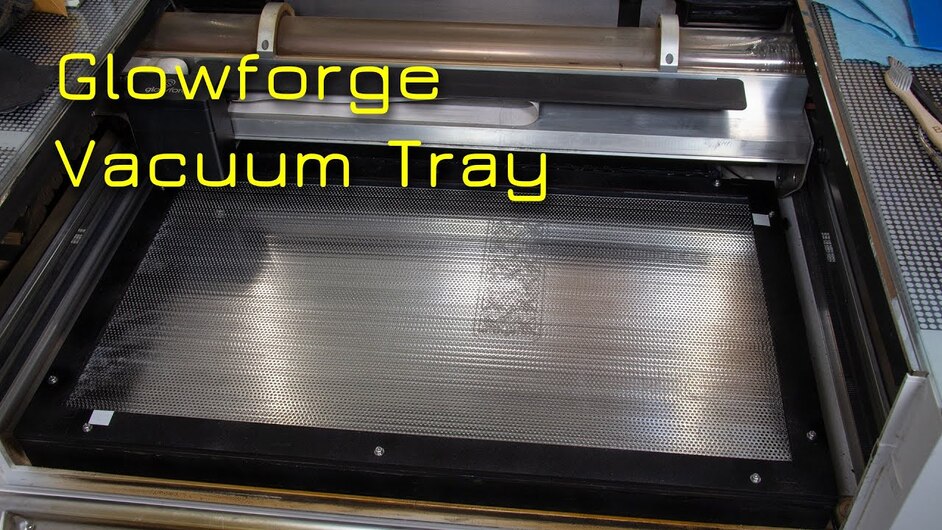

The tray is Thick Draftboard. I lined the bottom with aluminum foil for extra protection in case any stray lasering gets through. It’s probably overkill but, I sealed the seams with silicone caulk to reduce air leaks. The cutting surface is a piece of perforated stainless steel plate sandwiched in a layered Medium Draftboard frame. That is held down to the rest of the tray using magnets, with an EVA foam gasket to help with air leaks.

My original intent was to use the same mesh others were using. I couldn’t get it as flat as I wanted. So, I switched to the perforated steel plate.

The fan box is Medium Draftboard with press-fit holes for the power connector and switch. The fan is bolted on to the end opposite the switch. This uses a 12v fan and a standard 12v power supply. The cord hangs out through the front of the lid of the machine. The electronics are basically a summary of the recommended parts from this thread.

I painted all the MDF black so it would look more finished and less cobbled together.

Cutting the plate steel without access to a shear was a new adventure for me but, worked out really well.

The cutting surface is a little higher than the standard tray and, the air assist clears the fan box by a hair. If I were going to make another one, I am confident I could shave some height off both components. It works well. So, I probably won’t, unless I run into problems as I use it more.

Here is a 1.6-minute video of it in action:

Blog post with more photos: Vacuum Work Hold-Down Tray - Evermore Stud.io