The chase:

So I made a fullsize tray replacement vacuum table. The idea is that it allows me to cut very lightweight materials without worrying about flyaways.

A quick disclaimer: It’s possible that this is a fire risk, airflow and contained spaces and all. I feel as though it isn’t, but I’m just a dude with a laser who thinks he’s got decent risk assessment skills. Use your noodle if you try something like this ![]()

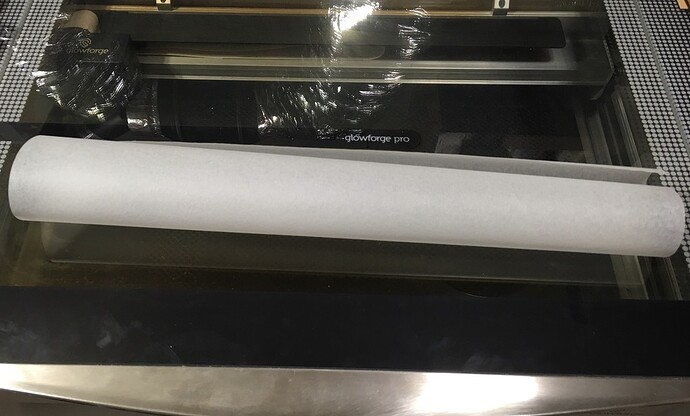

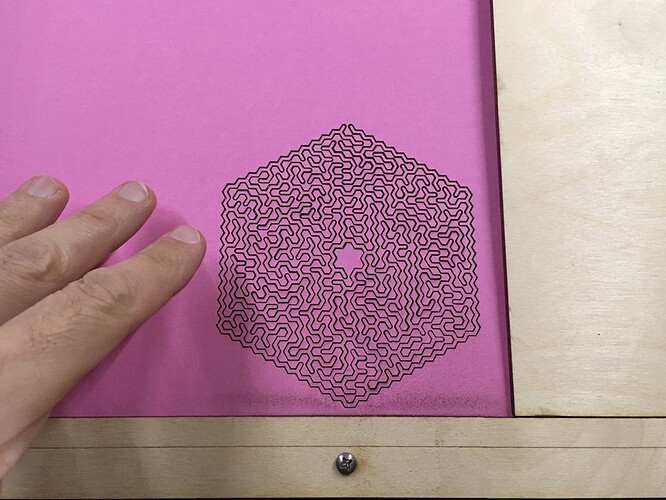

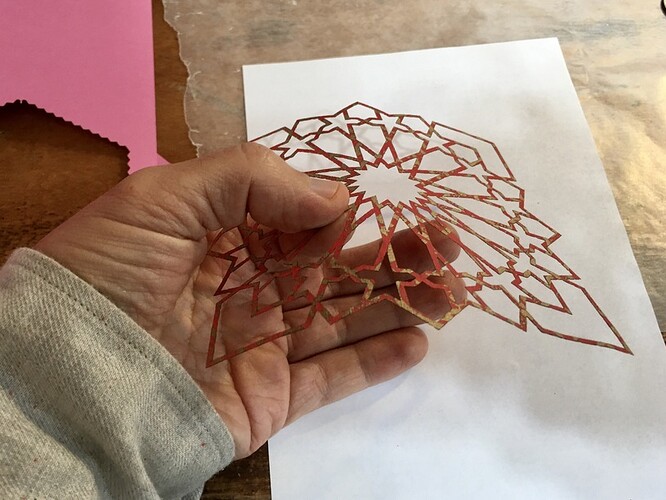

Say you wanted to cut some rolled trace paper:

When you cut it you would worry about the air assist picking it up and ruining your job or perhaps starting a fire. The typical advice is “get a seklema mat”, but as an old Cricut guy, I learned to really dislike sticky mat cutting solutions, and really wanted a better solution.

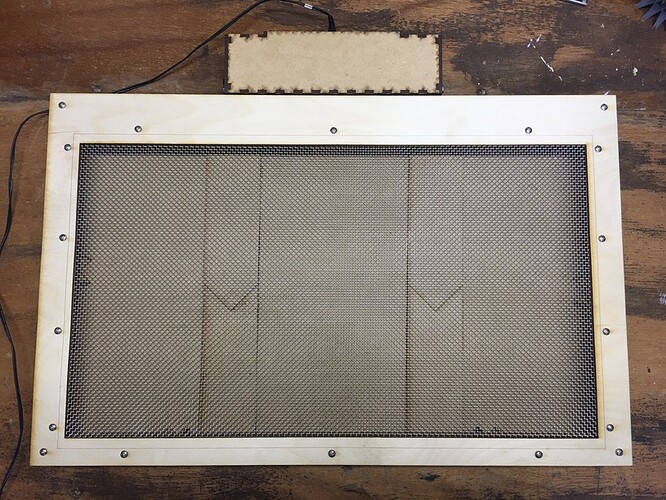

Enter the vacuum table project. Like most of my bigger projects I’ve been thinking about doing this for literally years, and only now getting to it. Check it:

Tahdah, secured, and ready to cut.

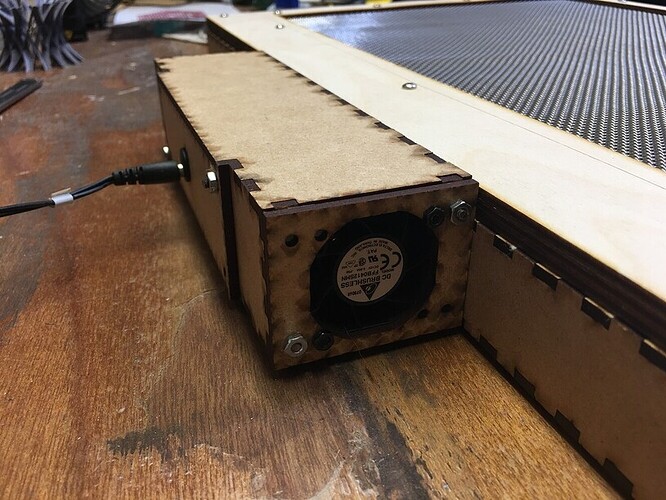

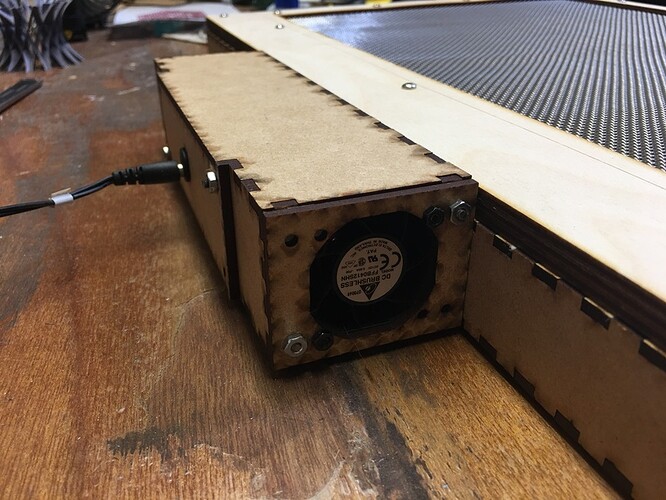

The vacuum is provided courtesy a small fan (very similar to the air assist part):

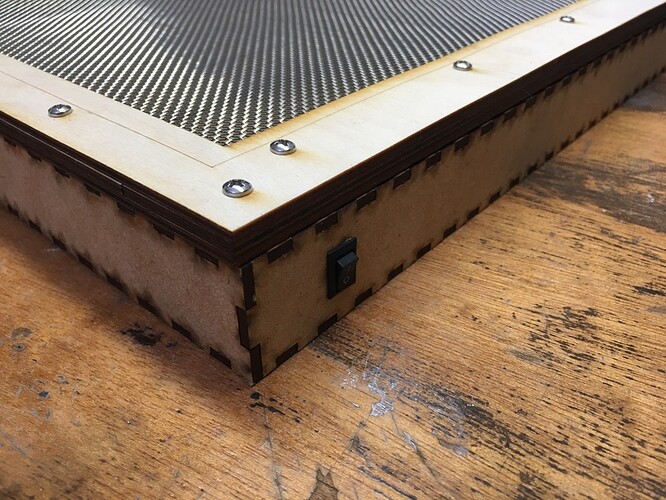

Power enters in the rear, so I ran wires up to the front corner switch to make powering on and off easier when the vacuum tray is in place. The screen is a 3 layer Baltic Birch ply construction with a heavy duty stainless steel mesh:

I didn’t take pictures before I assembled things, but I made a power distribution board inside the case so that I could add a second fan later. All I’d have to do is plug it right in to the extra red header on the board. Apologies for the terrible picture, but if you’re the sort of person who is thinking “huh I should do this”, chances are you know what you’re looking at.

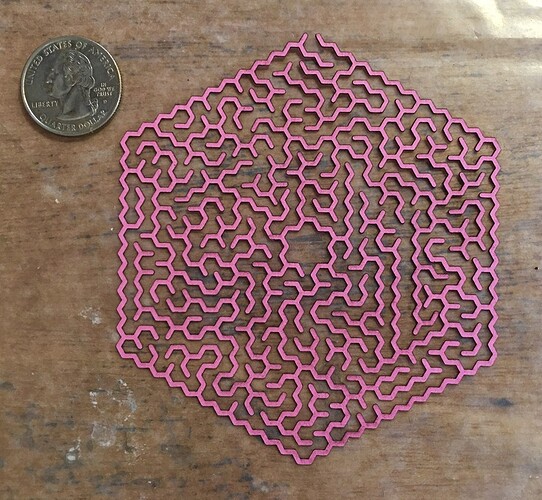

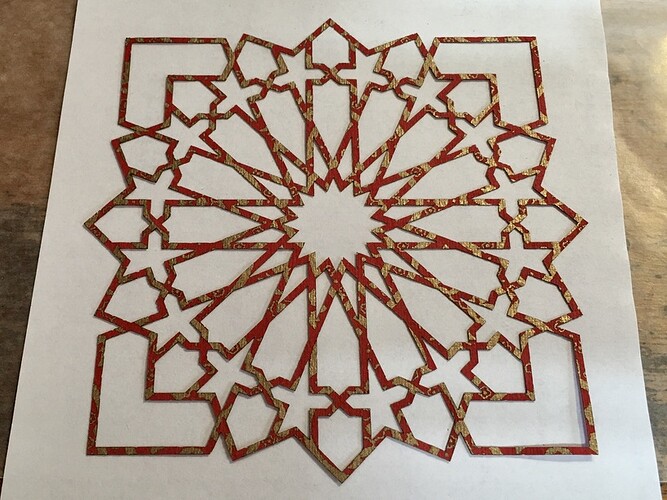

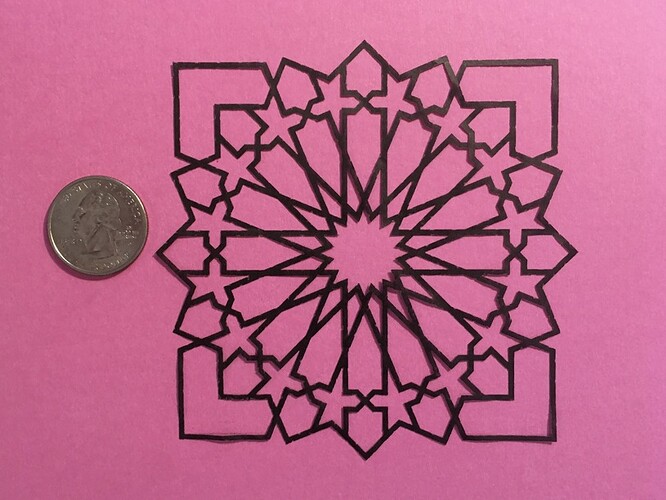

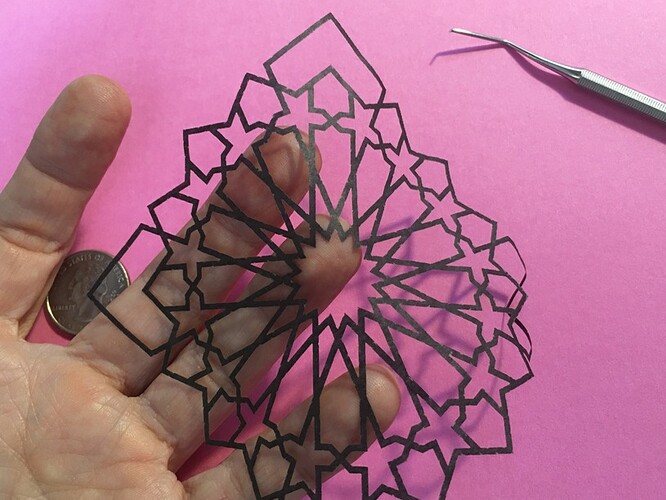

And finally, a few things I cut as part of testing:

(Cardstock, maybe 80lb? Fairly heavy.)

(Washi paper, much lighter.)

(Tissue gift wrap paper. Flimsiest stuff… it cut flawlessly, zero flyaways.)

Anyway, I have a lot more to say about it but I won’t bore you here, I’ll reply to what people want to know instead.

front door - and the power comes in the back…where? You comment somewhere about removing your fan - but isn’t there still an exhaust hose covering that opening? I also see your comment about the cable being able to go under the lid - I’m just curious what your solution is.

front door - and the power comes in the back…where? You comment somewhere about removing your fan - but isn’t there still an exhaust hose covering that opening? I also see your comment about the cable being able to go under the lid - I’m just curious what your solution is.