I’ve been thinking that as well. It seems like using the existing standard would be the logical choice.

Even if it’s not that exactly, it’s probably something similar as a brief intermediary. GFcode. :V

Yep! 3D printers use gcode to move the bed and print head and extrude and retract filament. CNC machines use it. Digital cutters use it. Plotters of all kinds use it. Lasers too, or something similar.

And 99% of the people using the machines to print, cut, zap and shave things don’t know that. They don’t need to. What Glowforge is doing for us keeps us from having to learn it. (good thing…i don’t have time…i can knock out some simple commands and that’s about it.)

If some of you guys who are interested in the more technical aspects of how the machine actually moves are up for some further reading… I have a link to the source that I use for writing 3D printer G-Code commands…over on the RepRap Wiki.

It’s a good read if you’re bored and have nothing else to do for an afternoon:

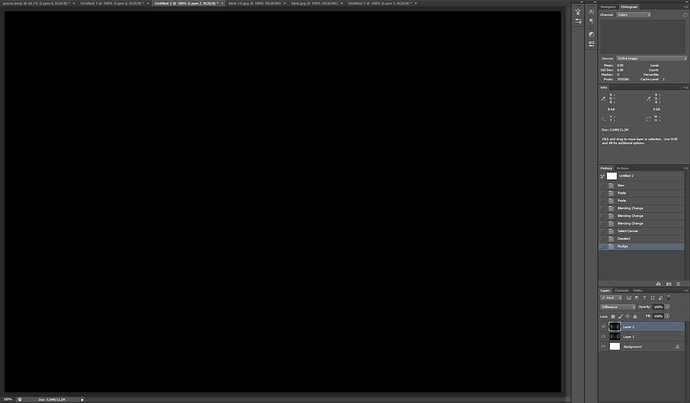

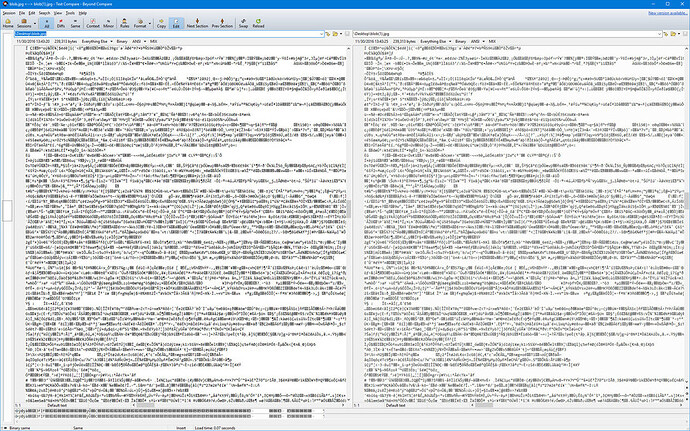

Wow, from these two images there is 0 deviation. I ran a diff on them and it came out solid black. They are visibly EXACTLY the same. The histogram is blank and std dev reads at 0. So either you uploaded the same image twice, or somehow you managed to get the exact same shot with incredible accuracy. I dont know if thats actually possible… but if it is, damn impressive

so… yeah… .wow

Not all of them do. I have a Zortrax M200 3D printer that uses their proprietary slicer (and only that slicer) to produce what they call “Z-code” for the extruder and motion control. Apparently Z-code is an encrypted version of G-code making it a closed system. Glowforge seems to be using a similar approach to machine programming. That makes for a well-defined system at the cost of allowing users to program outside the approved company boundaries.

A 3rd party has started making available hardware that allows Zortrax users some flexibility in how they print, but we are still stuck with that encrypted G-code. Despite my appreciation for tinkering, the closed system works pretty well for me and I don’t miss the open aspect of most every other printer too much because I can almost always get a good print, or at least as good as the printer is capable of producing without the need to futz with many variables. I’m hoping that the closed nature of Glowforge will work like that for me though I realize that it may limit what or how material can be cut or engraved.

tbh the times ive had to enter gcode manually are incredibly slim. most of that has been extrapolated to the interface where you move virtual knobs or sliders. Only when I upgrade my firmware and have to set the offsets of the print heads do I ever have to issue any commands.

Ive heard great things about zortrax printers. theyre obviously trying to keep tight reins on their ecosystem, but its still essentially running on gcode.

I use simplify3d, and its by far the best slicer ive used. it has a console window to manually enter stuff, but like I said I usually just use the GUI as its so much easier.

Oh, I agree, it was just the common proprietary nature of Zortrax and Glowforge that prompted my reply. One of the reasons that Zortrax stays proprietary may have to do with the fact that their slicer only recognizes Zortrax filaments so they are probably getting a significant revenue stream from that. You can still use a generic filament, like ABS, but results might not be as good if the generic needs a slightly different temperature than is hard coded by the slicer. A 3rd party device helps there, but you still can’t change retraction or a whole host of other features.

There are certainly times when I wish that Simplify3D was an option for me - it seems like an excellent slicer.

It is. ![]()

Sure - rub it in!

MakerGear M2s are on sale for the holidays , and available as a kit if you want to build your own…just sayin’. (Since they were the ones who sent me here, i figure turnabout is fair play.)

Thanks but I have to get my money out of this $2k Zortrax first. Here’s my latest print, an R/C truck fitted out with a technical gun that shoots Nerf bullets. It’s a design by MrCrankyFace on Thingiverse.

No doubt it would have been cheaper to just buy something similar at the local hobby store.

Awesome! (And yeah, we don’t think about the actual cost per unit with 3D printers…not allowed.)

With modern CAM and controllers we already don’t have to learn it. I’d say what Glowforge is doing against us is preventing us from utilizing it. That’s just me though.

The files are not only visibly exactly the same, the files are identical.

They are except the meta data says one is 5 mins older than the other. Could have been modified by the forum on upload though. But yes, I hashed them and they came out exactly the same.

Probably uploaded the wrong file by accident I’m guessing

I hope so.

But what if it’s not…either the wrong file uploaded, or a deliberate duplication with intent to defraud?

What if it’s….just that good?

Ooooh! Aaaahhhhh!

Ooooh! Aaaahhhhh!

.

.

.

.

And I’m messin’ with 'ya…I’ll bet he uploaded the wrong jpeg. I do it about half a dozen times a day.

Do you have the second picture? I was genuinely curious as to how much of a difference there was between the two

We don’t have any evidence of long term drift, so it’s the same thousandth of an inch or so as far as we know so far.

Indeed. Early versions of the software used it exclusively but we’ve been slowly working to eradicate it from our codebase, as it’s a source of inaccuracy and inefficiency.

I believe so (although honesty I haven’t tried it) - Tony and I have been discussing this thread and thinking about ways to simplify what everyone’s trying to accomplish.

JoshForge broke - a hardware problem caused the microprocessor to reset. It’s something we only saw after many hours of use but have fixed on recent builds. But as a beta customer, we’ve asked Josh to defer questions to us because… well, he said it best.

Hm - I did a visual diff and there’s a ~1 pixel halo around the head. (I wouldn’t put it past me to actually upload the same image twice by accident). I’ll see if it’s still on Photoshop on my other machine so I can share.

I grabbed two more head images from the same machine. First, for scale, here’s the dimensions of the engraving. This is the actual file used to engrave the head.

Now, the two files.

Finally, here’s a diff.

As you can see, it’s not offset, which would come from the head being inaccurate - it’s warped so one’s a little bulge-y relative to the other. That’s probably because there’s a crumb in the lid, keeping it from closing all the way. We will be able to compensate for that eventually, but for now, it appears to be our biggest source of error.

Easy solution: add 15000 micro nozzles to the lid to gently blow dust and dirt out of the way.