@artoftheprose Thank you SO much for sharing this! I’ve been intimidated by boxes until now because I could never get my joins / kerfs right. I needed a custom box last night and am so glad I searched the forum and found your post. This took me all of 10 mins. Thanks!

Excellent.

Oh good! It’s saved me MUCH heartache as well!

Is there a way to use box-o-matic (or other program) to make larger boxes that wouldn’t fit in a glowforge? For example, design two smaller halves of a larger box that fit together to make one big box?

You could make a box where the largest panel is 10.9x19.5". Then take the resulting PDF and move the individual pieces into the cut area one at a time.

Same with Festi. with a bit or work you can even use illustrator and setup glue ups. What’s your end goal?

My end goal is to make some planter boxes. I want to make one specifically for grass for my cats. I have a space that would be perfect but need a longer size box than I can make with my Glowforge basic.

Butt two pieces together and make longer parts… it’ll work nicely.

Wow, I hadn’t seen that post. Those are gorgeous!

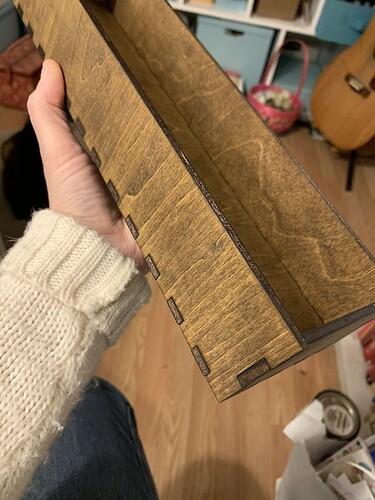

Just started using box-o-matic and it’s definitely easy to use. My first box had came out really well except that the tabs were a little loose. Definitely not a tight fit. What drives that in the app? I thought it might be the kerf so I started shrinking that but it didn’t get me where I wanted and in the end the tabs started being too long. I’m using home depots 1/4 purebond birch that’s precut for the GF. I used my calipers and came up with a thickness of 0.1995" and a kerf of 0.006"

It’s defiantly the kerf setting you want to play with, but I think you have the direction backwards. Imagine if you were to tell the program there were 0 kerf, when there really is one. This is equivalent to doing no kerf compensation, and you will a loose fit cause by the kerf. To tighten up the fit, you need to tell the program you have a larger kerf.

I always get this backwards too. What you have to remember is that the kerf is the kerf – that is caused by the laser and the material. What you can adjust is the kerf compensation in the various programs. I have suggested to the author that he put something about this in the program, but he hasn’t gotten to it yet.

Can anyone re-upload the file for me please?

So, I want to try this to make boxes. If I want to add artwork to the sides of the boxes do I just create the box using the app then place it in a different design software such as Affinity Designer, AI, or Inkscape? Is it really that easy?

Create the box. Open the box in the interface. Drag your artwork onto the box in the interface. Done.

Just go to the website: http://getboxomatic.com/

Awesome! That’s my next project. I have a bunch of ideas that require a box. Hoping I can speed things up because trying to make those little tabs…well, I’d rather not!

Two years later and you are still the MVP. Good grief. I can’t believe I just found this post.

This app is grand! Definitely has helped in box designing!

Thanks this will save the time of trying to Butt joint them by eye.

I can’t get this to download. Does anyone have an updated link to box-o-matic?

Thanks so much!