Extending the discussion from:

I picked up some all-purpose chipboard from Dick Blick (All-Purpose Chipboard | BLICK Art Materials). This isn’t archival quality but it will do really good for testing. (Related: I’d really like Eska Board, but it’s impossible to find and their USA Sales doesn’t seem to reply… ) I ordered enough of the .10" and .05" to meet the $35 minimum for free shipping. Seventeen sheets total of 28x44" chipboard, weighing 40 lbs - shipped for free. They must have one helluva deal with the FedEx folks.

I have a Logan Mat Cutter with a straight cutter on it and this stuff isn’t impossible to cut, but it takes more effort than you standard matboard (or double-ply matboard for that matter). I’m sure it will wear out some blades but blades are cheap. The .10" described material, calipered out at .102" - not too bad! I haven’t calipered the .05" described material.

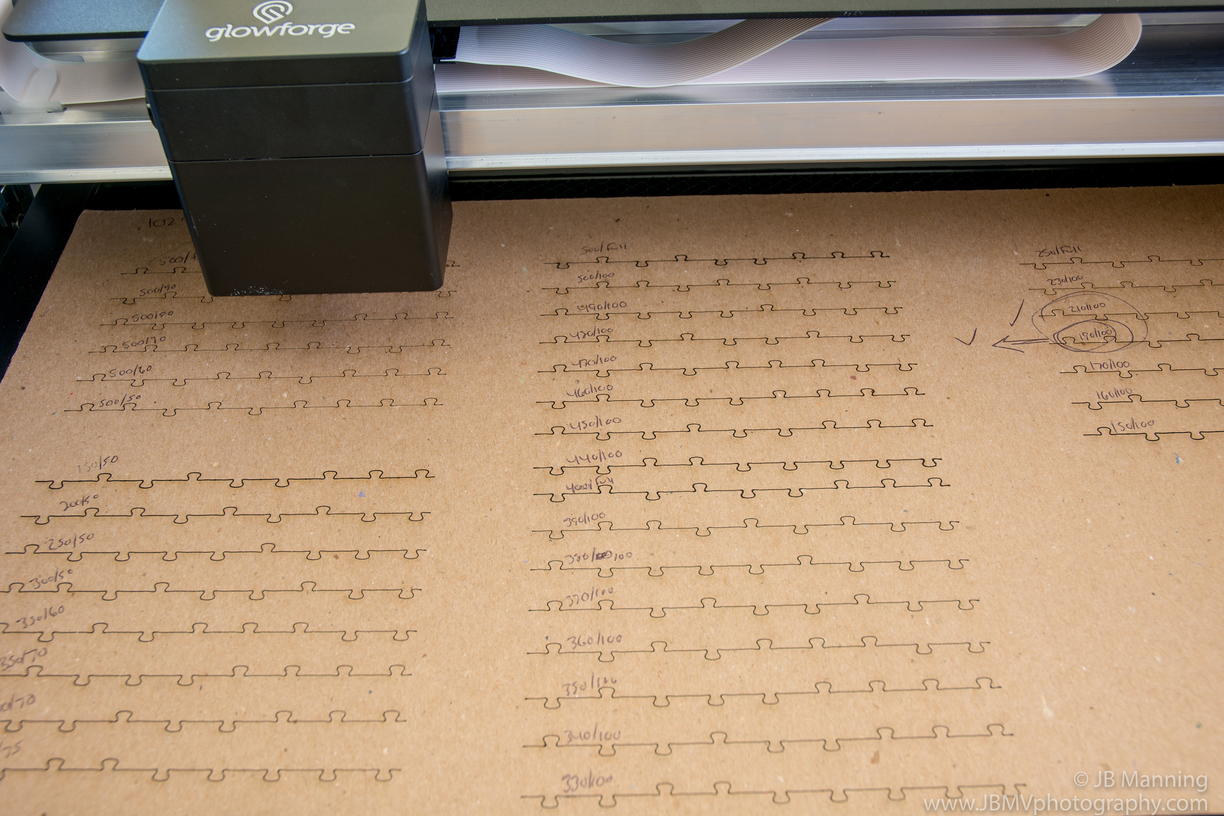

First, I needed to do some testing.

There is definitely a difference between “100 precision power” and Full Power. Full power really gets after it! I’m using this material unmasked and Full Power was leaving a little too much surface char and side char. I ran through a bunch of settings to see what would work best for getting through but leaving the material in as good of a condition as possible. Ultimately, I settled on 190/100 for through cuts. I’m going to refine this a little bit and feel that somewhere in the 180’s will make a perfect cut. It cuts very nice where it’s at, just barely kissing through with my photopaper on. But, a hair slower might make it easier to disassemble. Or maybe the Glowforge is just too damn good ![]()

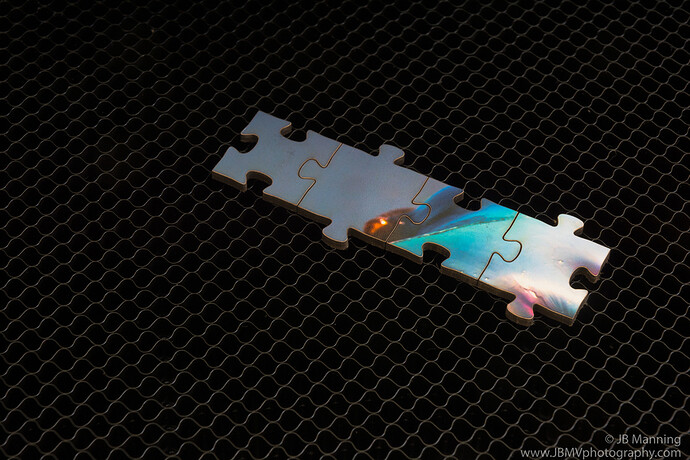

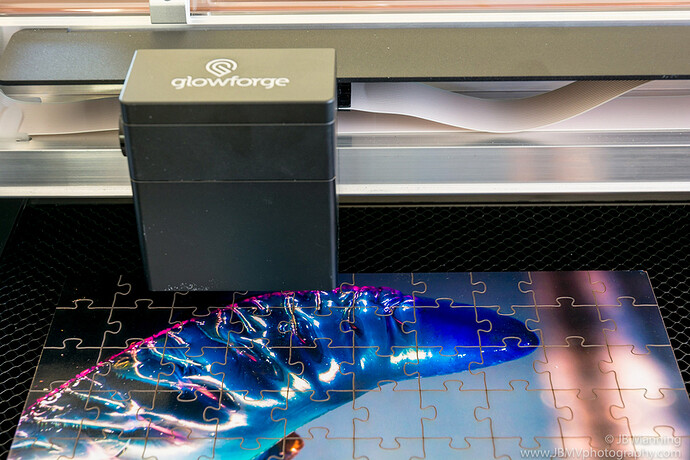

I have a bunch of prints laying around so I grabbed an 8x10" and hit it with 3M Photo Mount adhesive. A very light layer across the width, and then another light layer that runs across that first spray. I let it sit for about 90 seconds and adhered it to chipboard. No problemo.

The chipboard and photo mount calipered at .106". My calipers are cheap - but the paper oughta be a hair thicker than that.

I used the same 190/100 cut settings and used no mask on the photo paper. I don’t remember if I had a sealant put on these photos or not but the paper picked up zero smoke stain. I’m going to switch adhesives next week so my cut settings may need to change. The 3M stuff is great for doing this on a small scale - but for larger prints, it just costs too much per square foot.

The puzzle template came from:

http://www.wolfiesden.com/Laser/PuzzleCreator.asp

Regarding that template - it lays everything out nice in rows and columns that are groups and compound paths. I uploaded it “as-delivered” initially but the Glowforge really wanted to jump all over in making the cuts.

I separated out the rows and columns and assigned them different stroke colors. The Glowforge still didn’t run each consecutive line like I was hoping, but it turned out just fine.

One problem with the puzzle generator is that the interlocks and pieces are definitely not unique and will fit into several different places. I’m planning to draw more coordinate puzzles for my images (corresponding better to elements, colors, etc.) but the generator is great for testing.

One problem with the puzzle generator is that the interlocks and pieces are definitely not unique and will fit into several different places. I’m planning to draw more coordinate puzzles for my images (corresponding better to elements, colors, etc.) but the generator is great for testing.

(Gosh, you’ve got some gorgeous papers.)

(Gosh, you’ve got some gorgeous papers.)