I cut from the bottom in. Just be careful to cut an area similar to the one I show. It was carefully chosen to avoid wiring and keep from harming the integrity of the casing. You might be able to turn the + shape into a rectangle of the same size, though, if you don’t care about being able to screw the metal plate in again. It sits just fine in the bottom without being screwed in.

Unfortunately I only have one GF and didn’t take video of the process. Hopefully the images help, though!

Hi there, @coalakida! I’m just wondering if you proceed on the doing the mod? if so, did you have a video of it? I’m still in the contemplation phase of myself to doing this mod.

Thanks!

Friendly Neighborhood PSA:

Word of caution to anyone intending to modify their machine in any way. It might make it ineligible for repair if there has been any modification made to the case.

So don’t do it unless you feel qualified to handle any future repairs yourself.

This PSA brought to you by a roving neighborhood hedgehog.

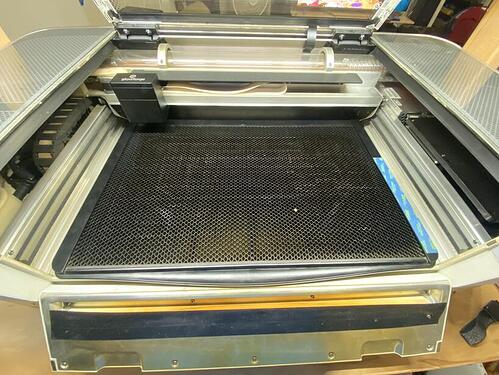

Here is my attempt. I now have ~8" of depth and nearly the same engraving area of the X & Y as the crumb tray.

Nicely done, @MechanicalGoose!!!

What tools did you use to do it, or did you just use the old, handy-dandy, dremel rotary tool?

Thanks for sharing your pictures! I’m close to doing it myself, a little more encouragement, and i’ll do it… hehehe

A little nudge the other way, the Glowforge repair facility will undoubtedly deem your machine a total loss if you ever send it in for service. (See above for a prickly PSA.)

I definitely don’t encourage doing it until at least after your warranty is up as Jules mentions and you are not worried about repairing anything yourself.

The problem is that there are a LOT of parts they don’t make available to the end user. So if you cut the bottom out and you blow a power supply… There ain’t no repairing it yourself and you have yourself… a paperweight.

True they don’t offer everything but that doesn’t mean it can’t be acquired or substituted elsewhere. For your example the power supply is an 800w power supply made by Neosen. There is also already a 3rd party control board in the wild.

Where were you about 4 months ago when my powersupply died?

You got a url or part number for that? Googling, let’s see if I can find it.

Hmm nope. google was not being forthcoming.

I found the info online but it doesn’t give a manufacturers part number. I understand the high voltage connection to the tube is difficult to transfer so hopefully it never comes to that.

To the best of my knowledge, it’s not a part you can buy. They may be the manufacturer that sources the part for GF, and it may be based on a generally-available product, but it’s not a plug-and-play “off the shelf” part available to the general public.

This comes up many different applications. In the automotive world, people are hunting down (for example) replacement turbos, and find part numbers on OEM stuff, but the actual components are custom built for that specific vehicle and not sold in that configuration, only supplied to the vehicle manufacturer for distribution through their parts supply network.

One of the original delays was they had to redesign the power supply. Until one is actually sourced outside of a repair I would be cautious on assuming it can be obtained.

^^ that’s true. As I recall the first of the 6 month delays was due to the company struggling with a source for their requirement, which suggests one with the needed specs wasn’t readily available.

At the time Dan said it was the continuously variable control of the power output - required for “vary power” handling of engraves (& 3D engraves).

That doesn’t surprise me, I remember marveling at that when I was engraving @mpipes Diamond knurl pattern watching it ramp up and down sculpting that file at full speed.

HELP!

I nicked one of the tubes, how do I figure out what that tube was for and how to fix

Hi, that is unfortunate! What do you mean by tube? Can you post a picture?

There is only one “tube” in the Glowforge, and that is the one that houses the laser. If it is damaged, the machine will have to be sent in for repair.

You might want to open a technical support case in Problems and Support instead of posting here.