This kind of thing is why I absolutely can’t get anything done, but curiosity drives me like a cat…

/uploads/db6859/optimized/3X/6/d/6decb4a2c5527dfbcb7b26abb3f27c1e55457fb5_1_371x500.jpg

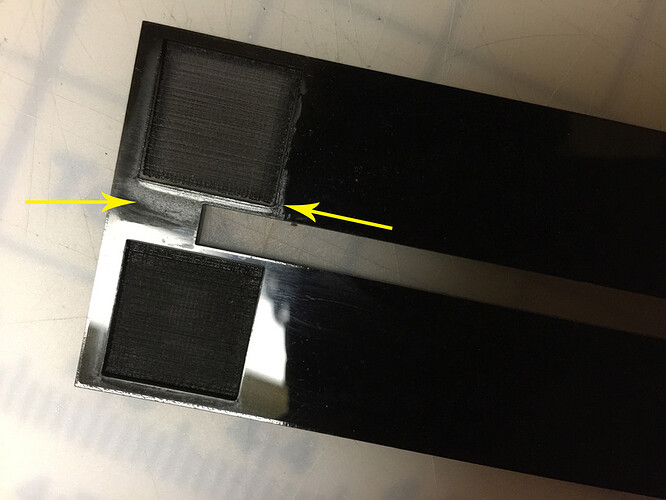

I wanted to see if I saw the same problem with the striations that you saw on that non-Proofgrade opaque acrylic, so I broke out the black Proofgrade and engraved a couple of little squares on an offcut.

From a distance - nicely smooth at 340 LPI. I had peeled off the masking before the engrave this time, and there was a lot less white striations and buildup on the material, but there was still a fine white ashy powder that must have been residue from the acrylic. It was equally distributed.

The good news is, it washes off with an application of 50/50 vinegar and water. (There must be oils of some kind in the acrylic, or it wouldn’t require the vinegar, but it does.)

So I washed off the bottom square and left the top one as it came off of the machine for comparison.

This was focused right at the top of the acrylic again. I’m just not seeing those striations. Definitely no ripples. The bed of the engrave is as smooth as the cast pattern allows. (And I still see the vertical lines more clearly from the acrylic.)

Up close on the bottom square you can see the vertical lines even more clearly. (Still a little bit of vinegar in the edges - didn’t see it, so it’s a little shinier there.)

That smutty smudgy residue on the shiny surface is caused by the air-assist blowing the smoke across it - it scratches off with a fingernail, but it’s stuck on there pretty thoroughly. It doesn’t just wipe off.

I can think of only a couple of reasons why it might be happening on the machine you’re testing and not on the one I’m testing.

It might just be due to differences in the material. The PG stuff seems to work pretty well, even the black opaque. It’s completely smooth. (If you’ve got some left it might work better if you want to try an engrave on that.)

It’s possible that we have different tubes in our machines, and that this one is one of the more powerful ones. (I don’t know.)

(If that’s the case, it’s definitely one of the better arguments for going with the Pro model.)

If you try an engrave on some of the black Proofgrade though, and you still get the striations like that, you need to hit the GF team up with a report. Maybe the unit you’re testing has a focusing issue or something that they need to know about.

Oh yeah…good one!

Oh yeah…good one!