We’ve all thought it: Why doesn’t the laser just follow the shape when engraving?

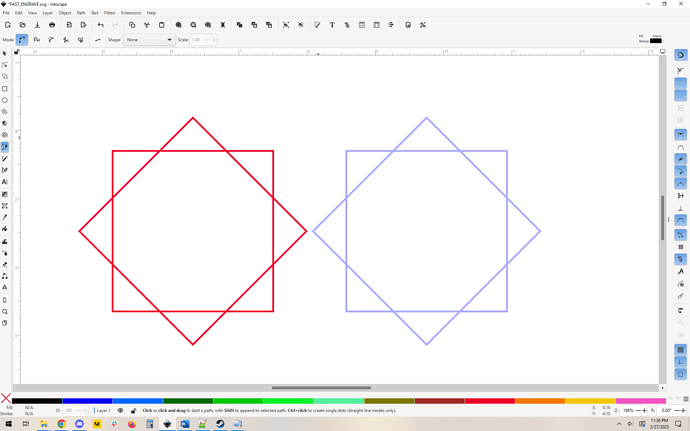

So I thought I’d manually try to make it happen. I made 2 shapes, line art with 0.025 stroke width. Traditional filled shape in red, parallel lines in blue:

I’m calling the blue technique a “score engrave”.

Details:

These are both “engraving” at roughly the same LPI: 340 for the traditional and 333lpi for the score. (In the score engrave, the lines are 0.003" apart)

1000 speed for the traditional engrave and cut 400 speed for the score engrave. These are kind of guesses, but they seem fair.

The short version: The blue method is far faster.

I ran it in two sizes, about 3" tall and about 6" tall.

Here’s the result:

| Size | 3 inch time | 6 inch time |

|---|---|---|

| Traditional Engrave | 9:25 | 32:12 |

| Score Engrave | 2:13 | 4:12 |

| Time Ratio | 4.29x | 7.67x |

The results are pretty clear, in terms of time. What do the results look like? I cropped the test images down and engraved Baltic birch.

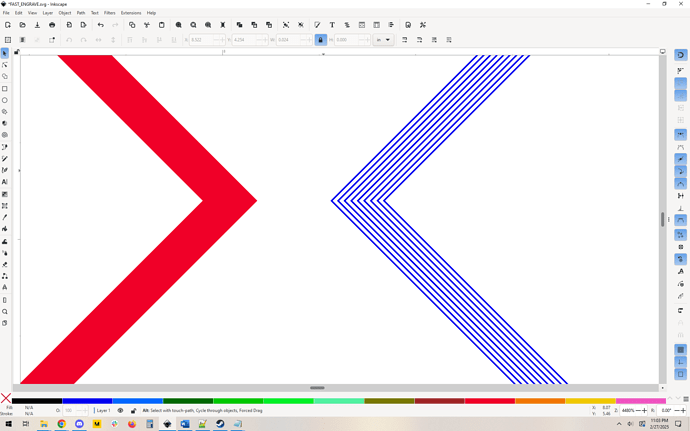

Side by side:

You can see there’s a little difference in how dark the engrave looks, that’s just me not getting the settings exactly matched. What is more important is the slight overburn in the corners. It’s more pronounced in sharper corners, but not too bad either way.

Also of note: The right side “score engrave” is slightly wider than the engrave. I think this was my fault, I didn’t take kerf into account, so I would expect the score engrave on the right to be about 0.006" too wide, so 0.025 versus 0.031. I haven’t measured it but that looks about right. Next time I would adjust for that.

Traditional engrave detail:

Clean, but you can see the clear “U” shape of the engrave. The edges are not as crisp as you get with a score engrave. See the next picture.

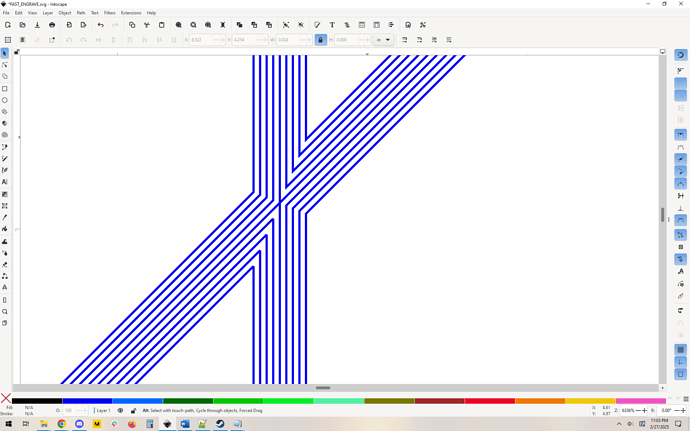

Score engrave detail:

Flatter bottom, more consistent depth.

Score engrave detail (2):

Sharper edges, the points of the tight corners are sharper than the engrave. Not by much, but it’s there. Might matter if rendering text at small pitch.

My conclusion: the technique has merit. Whether it is worth the work to expand the strokes depends on your use case and aesthetic needs. I think they look pretty good, and at larger sizes the speed increase is profound. I’ll be curious to see if anyone tries to replicate this and uses it in a high volume workflow.

Why not just defocus to get wider lines? Defocusing does exactly that: defocuses. YYour corners will be softer by definition, the laser isn’t in focus. Also, it’s not the most predictable technique – with practice you might get a dialed in line width with a defocused engrave – but this is 100% consistent. I think this technique has an edge on those two points. Defocusing will be faster because it’s just one pass or fewer passes depending on how wide your desired line has to be, but this may be worth the tradeoff.