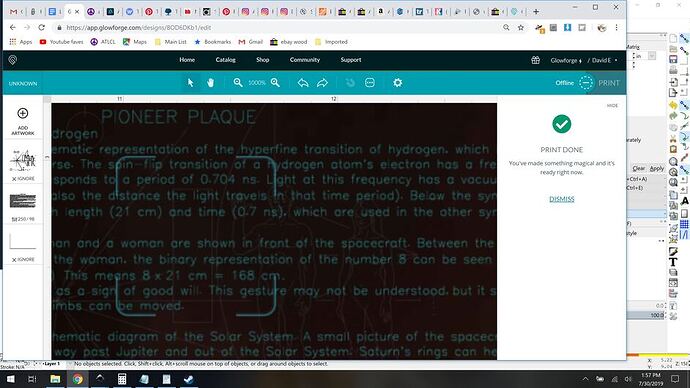

I’ve been seeing some issues with complex vector scoring [not engraving], resulting in inconsistent results. It seems that my machine is slipping or skipping steps, especially at higher speeds.

I ran two of the same engrave at different settings, first at 350 speed, then at 200 speed (thinking that the higher speed may have been the issue), and finally at 100 speed. It was only at 100 speed that I saw proper alignment, is this to be expected?

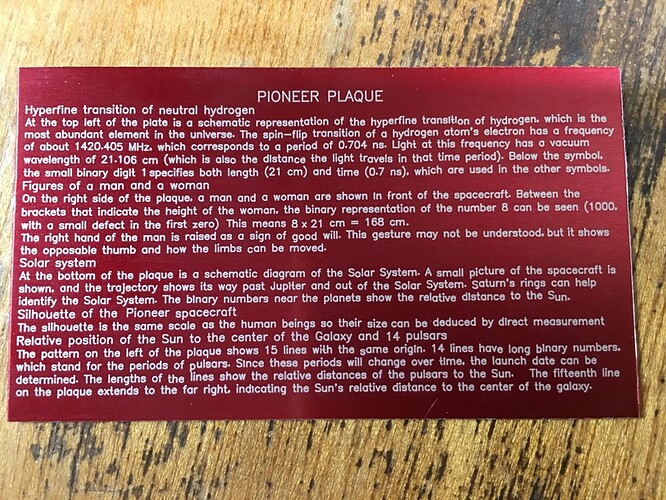

Here’s the 350 speed:

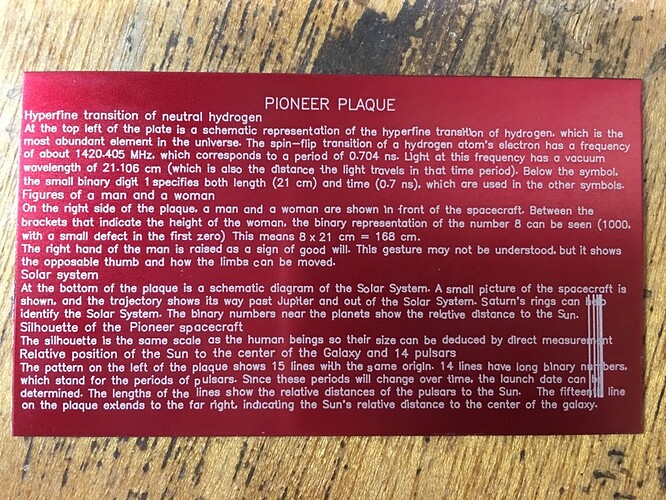

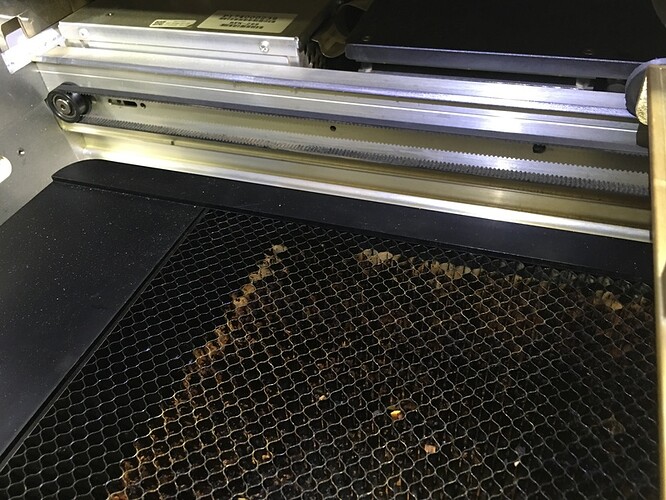

and the 200 speed [the vertical lines in lower right were from a previous score test to dial in settings and resolution, and are not part of this]:

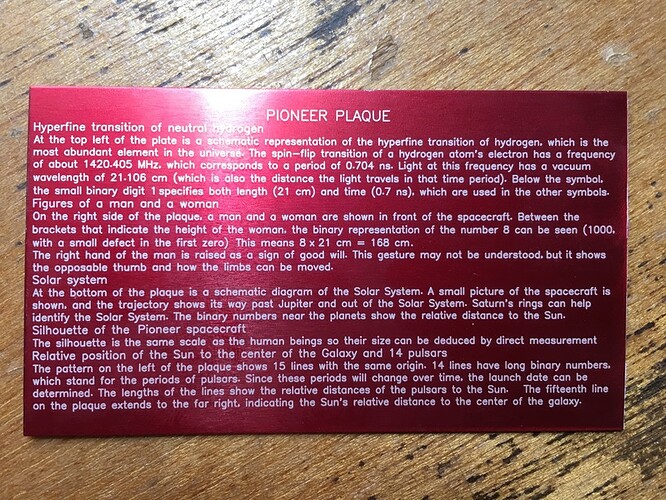

and the 100 speed:

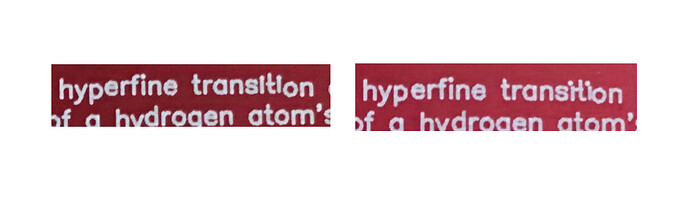

These are single-line hershey text fonts and look great until you spot the details. Note the words “hyperfine transition” in the first line of text:

If you look closely in the larger screenshots of the first two examples, more inconsistencies can be found, this is the tip of the iceberg.

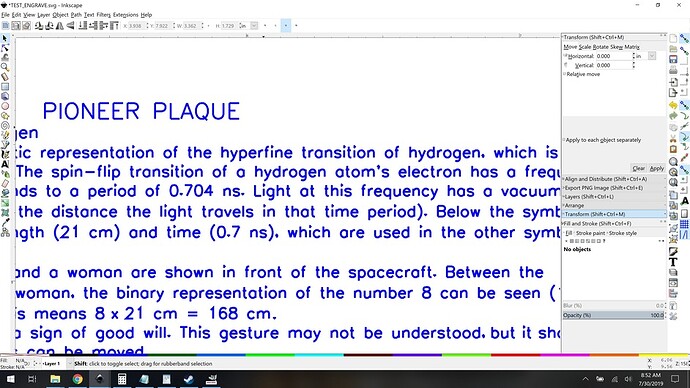

The original artwork can be produced upon request, but here’s a screenshot:

As you can see the “hyperfine transition” path is clearly properly aligned, so there’s either some sort of inconsistency in GF’s software, or there’s a physical problem with the machine.

Things I have done:

I manually moved the laser head and gantry through their full ranges of motion, feeling for inconsistency or noticeable resistance. It was fine.

I inspected the belts carefully for debris. There was none, but there is a light coating of typical laser grime.

I checked the belt tension. I am not sure what the tension is supposed to be, but the three belts I knew to look for had consistent “twang” to them, so it doesn’t seem like any of them are particularly loose compared to the rest.

I checked the crumb tray for wiggle or debris, there was none.

My materials were held in place very securely, there was no movement of the material.

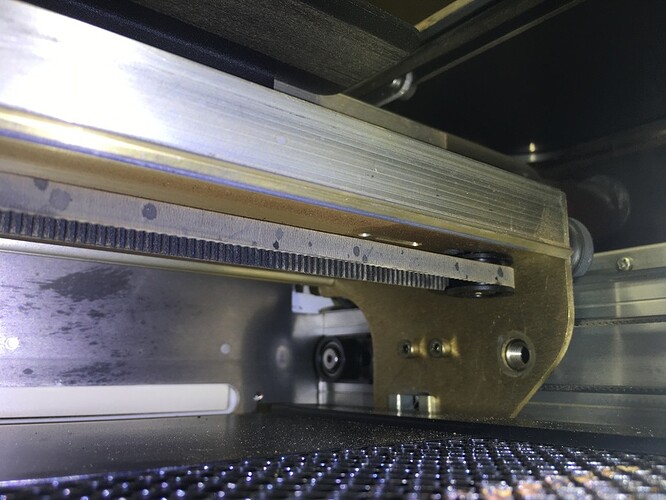

I’ve seen similar reports, they end in requests for specific pictures in other threads, so here you go. Closeups of the belts and wheels:

Left side:

Back

Front

Right side:

Back

Front

Gantry belt:

Is there any way to improve this situation or is it a limitation of the hardware? Can you give any guidelines about this sort of thing?