Understanding the interaction between your tools and materials is critical to making parts that fit well. A key metric to understand is kerf: the amount of material removed by a cut. Compensating for kerf is the difference between joints that are sloppy or that fit with just the right amount of force.

Even though a laser cutter removes only a fine amount of material, that slight difference in dimension between your plans and the physical material adds up. It’s worth noting that your kerf can vary between batches of the same material, power and speed settings, and over the lifetime of the machine. Because a laser beam is only in focus at a specific point, the kerf also varies throughout the thickness of a cut.

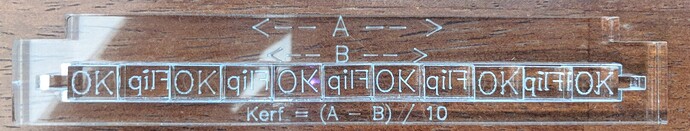

Here’s a jig you can use to measure kerf (right-click, save as):

It works by comparing a reference length (A) to the length of a set of blocks (B) which have been cut from the same stock. That difference, (A-B) is the sum of the kerfs of each cut. It’s much easier, and more accurate, to measure this compound kerf than to try to measure the kerf directly by cutting a square of known size.

Assemble the jig

Each block has OK or Flip engraved on it. This allows us to compensate for the vaguely trapezoidal shape of the blocks due to divergence of the laser beam. We’ll flip every other block left-over-right. This example is made with Proofgrade Thick Acrylic to show you how the jig should be assembled. You’ll notice that the Flip marks are backwards and on the bottom of the block when inserted into the jig.

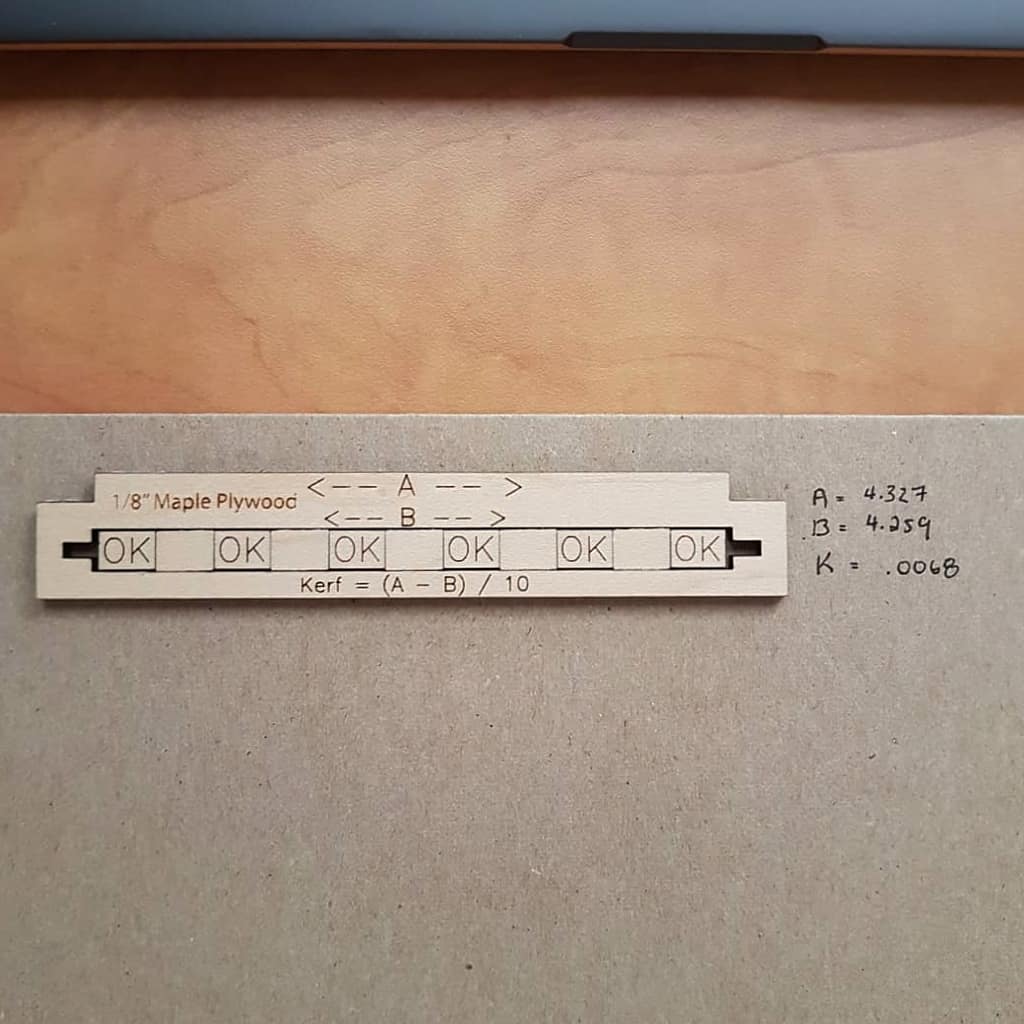

Measure the reference

If we had an ideal cutter that could make perfectly planar cuts down at the molecular level, the reference portion of the jig and the blocks should have exactly the same length. We’ll start by measuring length (A), the top-most width of the jig. You should take several measurements and average them together.

Measure the blocks

The jig has a couple of cut-outs to make it easy to insert calipers to measure the width of the blocks. Again, you should take several measurements and average them out. If you’re feeling adventurous, you can measure the blocks outside of the jig.

Compute the kerf

In this case, my average (A) value was 109.64mm and (B) is 107.5mm. This gives us (109.64 - 107.5) / 10, or .214mm / 0.0084in. This is a starting value that I’ll use, adding an extra thousandth of an inch for joints, or subtracting one or two thousandths for clearances. Please note that the acrylic used in this example shrinks slightly when laser-cut and will have a larger kerf than wood or other materials. In general, though, you can expect your kerf to be a few thousands of an inch.