numeric positioning would be a much better solution to this. the worst is snapping to a boundary that is just a fraction off of where you really want to be and cant get to it because of the ‘snap’.

i agree, i’m just thinking of solutions that would be relatively easy to implement and still mesh with the overall obfuscation theme that they seem to rely upon.

I think this is great for a general use case.

For a specific use case, it would be awesome if you could combine this with the jig approach @dan has above.

If you can tell the Glowforge “This is a jig”, then you place fiducials it will etch for you. Then, next time you make those part, tell it “I’m using that jig”. It should then look for the fiducials, and automatically align to the parts. That way, it doesn’t matter if your jig is perfectly positioned.

FYI, this is what we do at work with the LPKF laser. (It also does not have a 0,0 position)

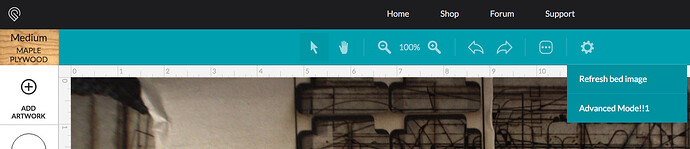

Its funny because by using some development tools you can do this in the UI right now to a degree, and it becomes apparent that the implementation of this feature would be incredibly simple. I know theyre trying to knock out the promised functionality now, but im hoping this is something that would be a quick add down the road. If they want to hide it a bit more they can always add an ‘advanced mode’ in the little gear menu that only has one item right now…

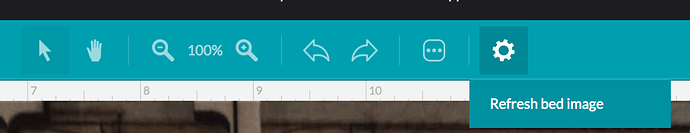

I wonder why they use that icon. That’s usually used for Settings. A refresh would seem to want the two-arrowed circle icon that is usually used for repeat or refresh.

The GF would need to use the head camera to find fiducials because the lid camera doesn’t seem accurate enough. We have never seen the head camera do anything other than measure the depth. However it needs to find edges very accurately for pass through and double sided mode, so once that is working I don’t see a need for a jig with fiducials.

I agree

Yes, my point is if the head camera is working then jigs aren’t needed and jigs with fiducials need the head camera to be working. It would be very odd if GF got the head camera locating fiducials before they got it working to find edges, so I don’t see why they would ever need to implement this.

It’s going to have to find a lot more than edges to make pass-through work! It also has to sense how far material has been indexed between cuts, and that may not be evident from the material edges alone.

Yes indeed, and it might be a very light engrave rather than a cut. Not an easy task at all, so I will be surprised if we see it this year or even next year.

because some things you want to engrave on dont have square edges

Will pass through and double sided need square edges?

trying to do a double sided cut on a circle will be troublesome to say the least

This could work. It would be great if GF would adopt this.

This might be my favorite line of the week.

It should be able to locate the edges of the L shaped jig, so all you need to do is put a placeholder for it in your project. Still no need for fiducials.

Great workflow.

Another benefit here is that one could make various jigs for different jobs which GF could pick up automatically using, say QR’s as fudicials. One could insert a jig, nest the parts to engrave and just press the magic button. GF would read the fudicials, align to the relevant 0,0, set the material and engrave settings associated with the jig and complete the job.

The whole thing could involve an automated workflow which also could solve the alignment cufveve…

If we get alignment that’s good enough to do double-sided cuts, then we have the means to align objects against material. If we have that, 0,0 isn’t necessary and, in some cases, could eliminate the need for a jig.

sure but isn’t the whole point of this discussion that that may happen at some undefined point down the road?