Wow, that one turned out great. Did you modify your picture to get everything so clear?

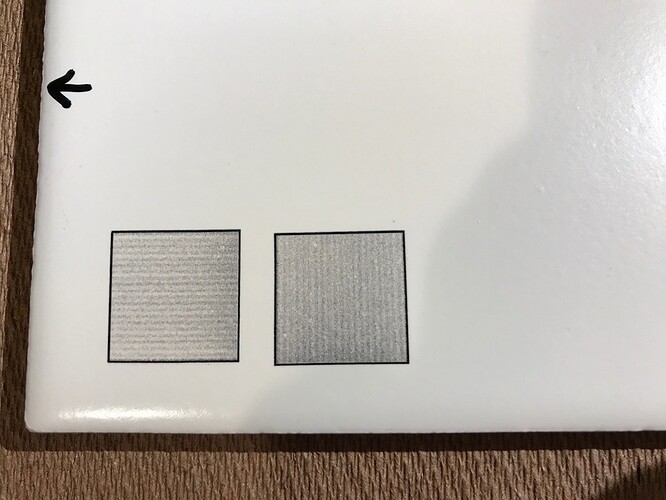

Engrave a solid square, then rotate tile 90° and engrave the same square on a different part of the tile. If banding is oriented the same on both, it’s the tile. If it’s rotated 90° on the second square, it’s the Glowforge.

Well, like I said in the post, I fiddled with the levels to make it very contrasty, as that’s what typically works on wood where there’s not much color difference between burned a little and burned a lot. This tile is a different beast, it allows for some subtlety. But instead of the shadows being crushed, it’s the highlights. The shoulder strap and hat is a good example. I’m used to things like cork, where that would be just solid charcoal on the bottom, but you’d be able to read the logo on the hat. Here the strap almost perfectly matches the source file but the hat is completely blown out.

I’m out of time but I think the next step would be to determine the lightest grey that shows up at all, and the darkest grey that is distinguishable from black, and map everything to that range. After a closer look, that banding occurs in the nearly white areas, so if I can avoid that tone it may be less pronounced. Of course I’ll try the experiment of rotating the tile too.

Here’s the exact file I uploaded:

Wow is right

just ordered the sampler pack of these. It’s your fault.

No, I do enough bad stuff on my own.

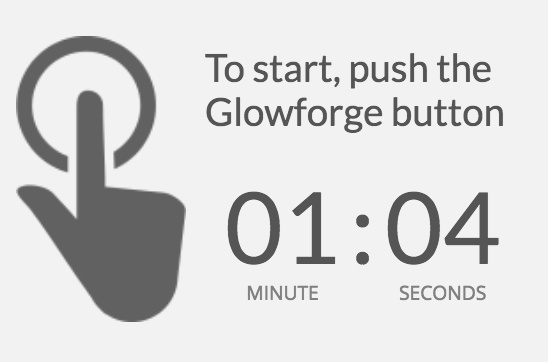

Here’s an update on those stripes. I did the test that @tim1724 described, and it indicates that the pattern is not in the tile, it’s coming from the Glowforge. Maybe something about the way the power is modulated at low levels? I hope this can be improved, because these tiles look great apart from that artifact.

Here’s the file if anyone else wants to try it. 1000/100/450. Vary power, min 0.

light_rectangle.svg.zip (717 Bytes)

I figured it was most likely the Glowforge, but I’m glad you tested it.

I really hope they can improve that.

The laser does that with engraves on acrylic. (More material impacted in the center than at the edges of the beam, depending on where it’s focused?)

I believe @takitus and @mpipes had excellent results with defocusing the beam a bit.

Not sure how that would lead to vertical stripes.

My earlier post demonstrates a variety of focus adjustments, with thoroughly un-excellent results. For now, if I do anymore tiles, I’m going to either avoid “vary power”, or avoid light grey.

The plot thickens!

Even though the head is moving left to right, it is doing fire-stop-move-fire correct? Every horizontal pass should stop to fire at the same spot on the x-axis. The beam is surely overlapping, but as it is being fired into a highly photon sensitive material I think you could still get vertical banding. Or am I thinking wrong again?

I may be wrong, but I would think that the beam would be modulated assuming continuous motion during the engrave.

However, all of the motion is controlled by stepper motors, and if the timing of each step is even a little off, there may well be some flutter in the horizontal motion. That would lead to some parts getting a little more dwell time than others. It could also be related to the tooth width on the belts…just guessing.

That was my first thought. I think it was in a video of that retired British engineer who turned one end of the drive belt over to the smooth side and got rid of banding that was exhibited.

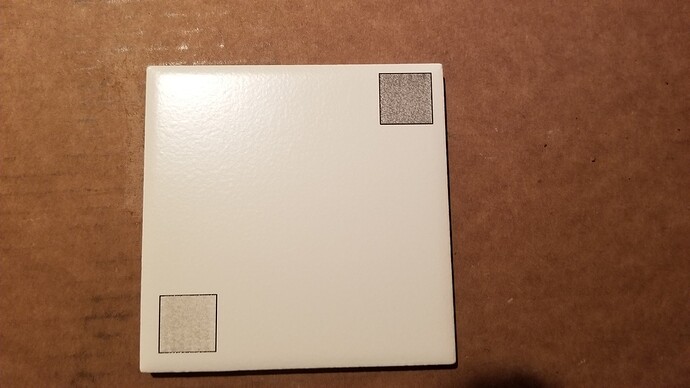

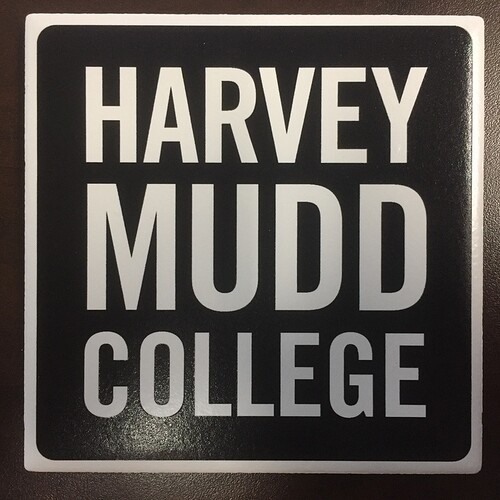

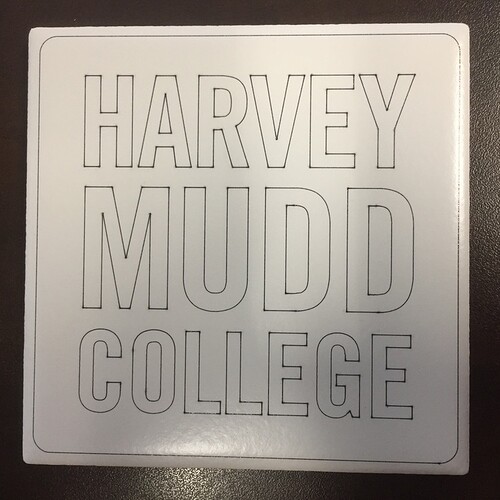

I just got my LaserTile today and gave it a quick try. On my Pro I get gorgeous solid blacks at speed 1000, power 100, focus height 0.290. I did this one at 340 lines per inch and it looks great, but I think I might score the path next time to give it a crisper edge. (Bumping it up to 1355 LPI would probably also get the job done, but I don’t want to think about how many hours that would take! Scoring the outline will probably be just as good and much, much faster.)

This is the 4.25"×4.25" tile in case it makes any difference.

That looks pretty crisp from here!

How long did that taske t o print, @tim1724?