The short version of my question: will the Design Catalog have parametric customization? (Something similar to the the McMaster Carr site or the various “parts” sites out there, like GrabCAD.)

Long version…

I’ve been playing with my laser cutter and one of the projects I’ve been working on is an organization solution for the board game “Small World”. For any board game players out there that have not tried the game yet, I highly recommend it!

I imagine that many people who have played it, especially if they also have some expansion packs, have noticed that the factory box was apparently designed by a jackass. The molded plastic tray in the box has slots that the pieces sorta fit into, but very few of those slots are sized appropriately. They’re either too big, too small, too shallow, or something else. The core game fits OK, but once you start adding expansions you start running out of places to put all the pieces. Some of the expansions come with additional trays, but they are far from perfect as well. I set out to make something better.

Here’s a pic of a prototype… (I’m only posting this somewhat-low resolution pic because I have a better design in the works)

I cut this one out of baltic birch, but I’ve also experimented with using acrylic (I threw a few boxes into the pic). Of course, these two materials may be different thicknesses (in this case, the acrylic is 2.8mm and the baltic birch is 3.1mm). The little boxes have tabs to help hold them together and align them and those tabs introduce a bit of a problem when designing something intended to be cut from different thicknesses of material: in order for the edge of the tab to be flush with the side of the mated piece, the tab must have a length equal to the thickness of the material.

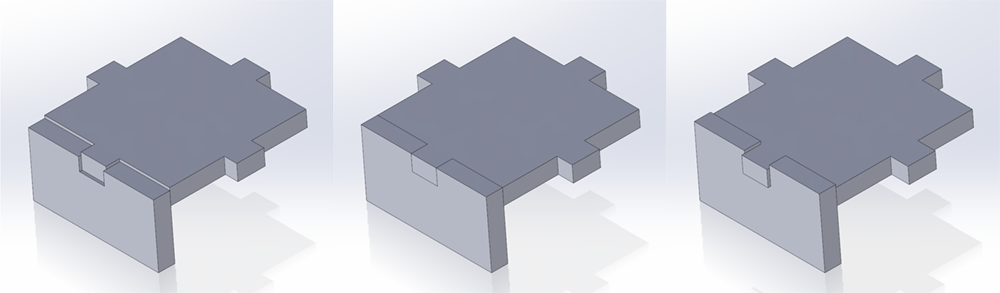

A lil’ image to show what too short, correct, and too long tabs look like.

If I were to buy a design like this in the Design Catalog, I would prefer that the tabs be the “correct” length for whatever material that I’ve chosen to cut it from. Are there plans to incorporate some parametric customization options into the Catalog?

If parametric customization is in the works, I’d be interested in hearing some details about it. A couple questions that come to mind are… (1) When will customization be available to customers? (2) Can a chosen parameter influence the price? (3) Can things other than dimensions be specified?

-

When?

Basically, I mean: pre- or post-sale? I can come up with reasons why only pre-sale customization and why only post-sale customization would be preferable. Letting the designers decide would prolly be best, but I could see that causing confusion. I’ve tried to write out my rationales for each case, but they ended up being pretty convoluted. I can attempt to expand on this question if anyone wants… -

Parameter = Price?

This is easy enough. If someone designs a box or something, maybe the price for the design could be based on the total volume of the box, or some other parameter. A jewelry box would cost less than a shoe box. -

Other stuff?

Say someone makes a… I don’t know… little rack for test-tubes. It would be nice if customers could pick how many test-tubes the rack holds. This, combined with the answers to 1 and 2 have big implications, IMO. Another thing that designers might want to customize using the store/software UI is text. Adding some simple text is easy enough, but it could be made easier within the store interface. For instance, maybe someone might want a word printed on all six sides of a box, it would be cool if there was a provision, provided by Glowforge, to place that text for the customer. Even if six instances of text sounds like something that would be “easy” to do by the customer, imagine the label being printed on all four edges of all six sides of the box.

Sorry for the long post!