You beat me to it! I used for the starting center .85 for the ratio and outer ring .950. Did 14 steps. Inner is 4" and outer is 11". Any tips for aligning the inner and outer correctly? [SVG here:]

Your all making me jealous right now as I am stuck at work

Thanks @mpipes for doing the test validation. If your laser is powered up what is the opt time estimator say for pg maple ply? At 11inch diameter

Is there any information on how big of an image the software can handle?

Not Rita, but I can take a shot at explaining it if you would accept my word for it…we had the same trouble with the digital cutter files created in CAD programs.

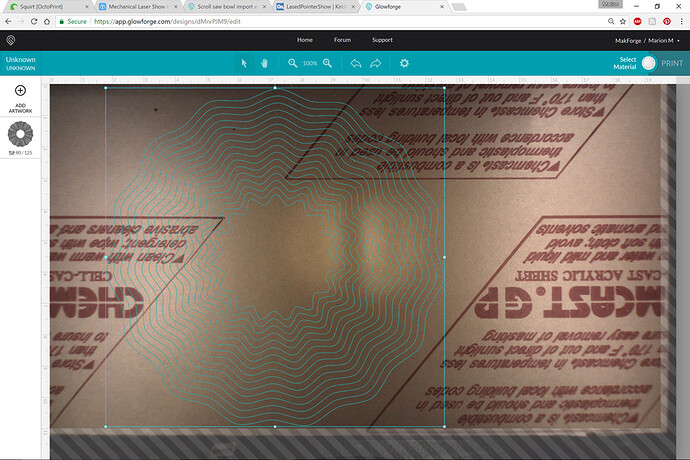

From @Clone 's original file that came from a CAD source you have a file that looks like this:

That has something like 30,000 nodes or so.

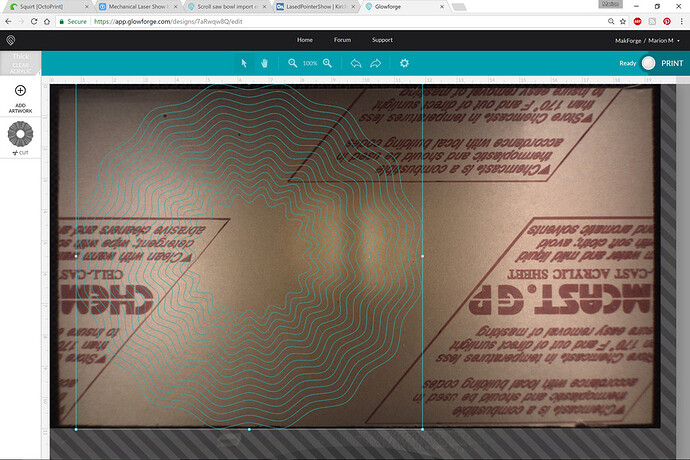

From the 2D vector drawing software you get an equivalent result that looks like this:

Haven’t counted them, but it’s a lot less than 30,000.

Most software has trouble with the first one. Not so much the second. You just want to keep the nodes to a minimum where you can.

The 2D vector programs have routines that can simplify the number of nodes if they are joined. The problem with a lot of CAD programs is that they don’t always export the paths joined. And if you’ve got that many nodes, joining them becomes impossible.

It’s generally more of a problem with curved lines though - so if you can design for curves in the 2D software you’ll have a lot less trouble.

I created the inner path. Hit Control-D to duplicate it directly in place. Then hold down Control and Shift while you scale it. Shift causes it to scale about the center point, Control constrains the aspect ratio, so the larger one stays aligned to the smaller one. Then adjust the curviness/ratio of the larger version as needed.

I’m getting 12:42 for time. The path display is showing it will cut the largest ring first. Might see if there’s a way to make it cut the inner first to avoid any possible shifting, particularly if you have any warp in your material. Maybe Inkscape has a “Change Direction” function for paths but I’m still green enough I’m not seeing one right off. I know other design packages have the feature, I’d expect Inkscape would too.

Nevermind I found it. Have looked at it a hundred times. Hahahahaha… They call it “Reverse”… but now the server/app is timing out so I can’t see if it changes the cut order.

Or you can manually switch the cut order in the GFUI. Tedious, but it would do it

If all the paths are the same color you only get one cut object in the GFUI.

However, if you make each line a different color, then it splits them all up into individual operations. In this case, there is no need to order them manually. The GFUI will automatically order them the way you want if you use the Inkscape color palettes that forum users have put together.

OI. you are completely correct, I just automatically assumed that each “ring” was a different color. And even then, didn’t think about the specific ordering of colors.

OK, so “Reversing” the direction of the path in Inkscape WILL reverse the direction the laser takes on that path, but does not impact whether it cuts the inside or outside ring first, so it seems it’s up to using color to change the order.

Ok. That is simple enough. I was making a new object and the points rotate in relation to the first one. Duplicating then makes it exact.

Book this one done! Thanks for everyone’s help.

Looks like the outer circle at 10.75" is about as big as you can do at one shot for the GFUI sizing limitations.

Add or remove one more star point and you’ll be able to eek just a wee bit more size out of it. See how the top has one point at the edge of limits, but the bottom has two points at the limits? If the Top had two points directly mirror-image of the bottom, you can maximize it.

I was thinking about that, but didn’t think to start with an even number of starts to get a better top and bottom.

Edit: Yippee. It goes to eleven! with careful alignment of the points top and bottom, 11 is spot on with sixteen points.

And the actual outside diameter tip to tip is actually larger than the 11" “flat” to “flat” dimension.

thank you all wow you guys where busy well I was at work.

using your method I created a new file and did a 2 min cardboard job

That’s a nice looking bowl. I like the cardboard too.

now I am in a debate PG plywood, or hard wood but PG hard wood is only 6 inch’s so maybe get some good wood together and do a glue up of something

Looks great!

I owe the credit to you guys, despite me having designed it in fusion you guys instructed on how to make it work in inkscape. hopefully some day GF will be able to take fusion / cad with out having to re work everything.

I thinking it will have to be a hard wood glue up, because I don’t think that wood glue will get a proper bond on the finished PG

Now you need a cut pattern which stays together and doesn’t require manual gluing! A hanging bowl with layers held together with tabs, like a collapsable bowl.