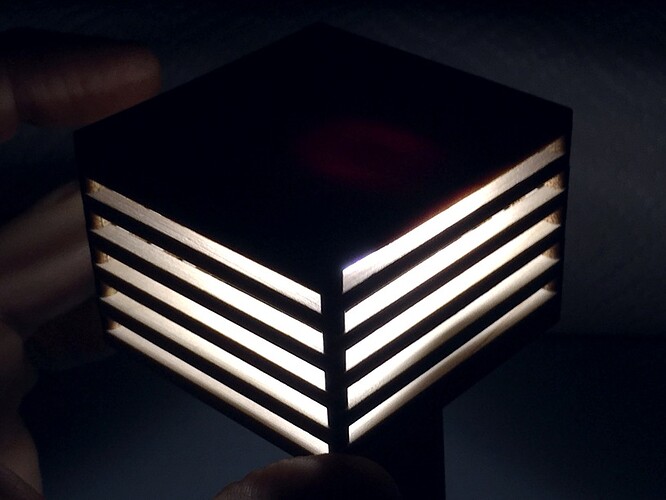

Hello, I apologize for my state of undress. I’m Slatbox.

Maple, 1/16" Brass pins

I started thinking about this idea recently, and this is a first prototype. Some notes.

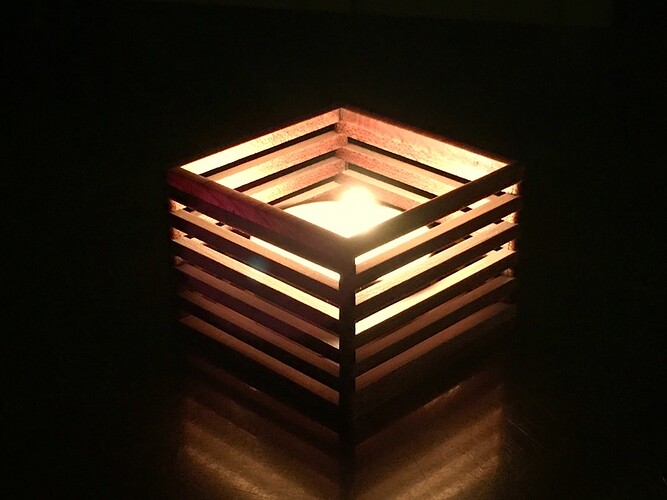

- The beauty of this design is that it’s really only three parts: a top solid piece, a bottom solid piece, and 20 copies of the side slats. It would scale up well.

- I went for a tight friction fit on the brass. As such, getting it through the holes was a bit of a bear. Solution: put the brass pin in a drill chuck. Spinning the brass slowly made it much easier to slide the wood pieces on.

- Cut the brass pins as close to the wood as you can, sanding them down is a pain, and messy. Metal dust wants to discolor your pretty maple.

- Cut all your slats with the grain of your wood, they will be far too weak otherwise.

- This is especially relevant with the top layer (a hollow square). The cross-grain sides must be supported by a slat directly below. I found this out the hard way.

- I didn’t glue it up in general but I did glue the top layer to the support slats, and the bottom is glued to the first slats. The pins could be tapped loose (or you could yank the box apart), but they shouldn’t work themselves out on their own. As such, this is not as strong as a solid wood joint in some ways.

- All wood is 1/8", non proofgrade solid hardwood.

The slats are cut to be 1/8" wide, with a 1/8" diameter round end. The end result is a pretty clean corner joint that feels natural.

Maple, 1/16" Brass pins

You can see how the bottom slats are glued to the base, on opposite sides from the support slats on the top layer. It was an aesthetic choice, I suppose there’s no wrong way to do it, but I wanted it to be equally “slatty” on each side. You could theoretically cut hollows on the bottom piece to make it even slattier, but I didn’t go that far.

Maple, 1/16" Brass pins

I decided to leave the edges of the slats “lasery”. I initially intended to sand the sides down and expose the bright maple, but in the end I liked the contrast so I went with it. Sometimes you choose the design, sometimes the design chooses you. That being said, I don’t like to oil/finish the lasered edges until the sticky residue has set – it can smear and make nasty discoloration. I will probably come back and oil this box in a few days.

Maple, 1/16" Brass pins

As for what kinds of applications there are for this, who knows. It’s kind of fun when you light it, so maybe it would make a good shade?

Final thoughts…

This technique could be used to make arbitrary overall shapes. Cut a star-shaped base and top, and voila star-shaped box. Cut an octagonal base and top, voila, octagonal box. Cut 2 sets of slats long, 2 sets short, voila, rectangular box. I think the only limit for this technique as is would be that the design would need to have an even number of sides.

With proper short pins, you could also make woven surfaces, or use pieces to make a sort of negative space design. With various length links, it would be easy to make a dimensionality or surface texture to things here. If I were to do that I would look for fixed-length pins that you could just slot into place. As a proof of concept, I think it worked pretty nicely.

Also, yes, “slattier” is now a word. Zip it, word nerds!

A quick bonus: scale of the slats.

Maple, innovation? New to me anyway.